A wood connection method utilizing wood shrinkage rate

A technology of wood shrinkage and connection method, which is applied to wood processing appliances, manufacturing tools, etc., can solve the problems of poor connection strength, high use cost of connectors, and high requirements for drilling accuracy, and achieves the effect of reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

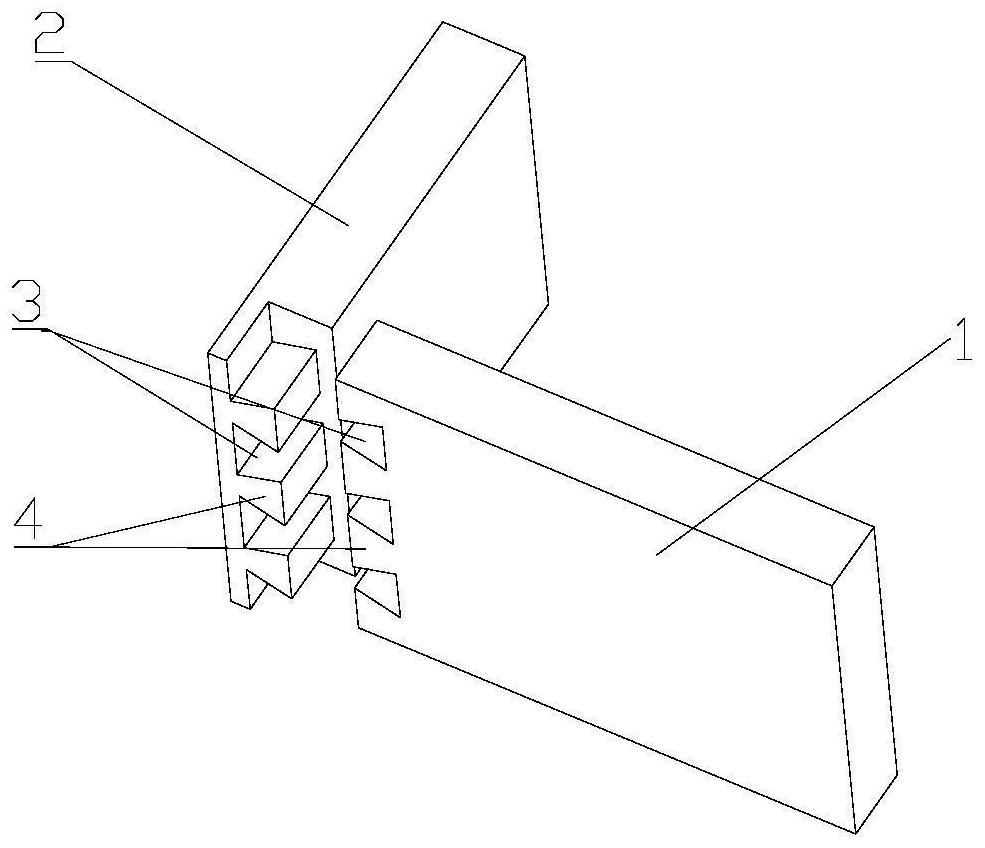

[0030] as Figure 1 As shown, a wood connection method using the dry shrinkage rate of wood, comprising a first wood piece 1 and a second wood piece 2, the first wood piece 1 taken from hardwood, the second wood piece 2 taken from coniferous wood (cork), the dry shrinkage rate of the first wood piece 1 is greater than the dry shrinkage rate of the second wood piece 2, comprising the following steps:

[0031] Step 1: Dry the first wood piece 1 and the second wood piece 2 respectively, drying to the same moisture content;

[0032] Step 2: On the first wood piece 1 and the second wood piece 2 are opened the same connection port 3 and the connection block 4, the connection port 3 and the connection block 4 have the same shape;

[0033] Step 3: Connect the first wood piece 1 with the second wood piece 2 through the connection port 3 with the connection block 4;

[0034] Step 4: Dry the connected first wood piece 1 with the second wood piece 2.

[0035] The method described in the prese...

Embodiment 2

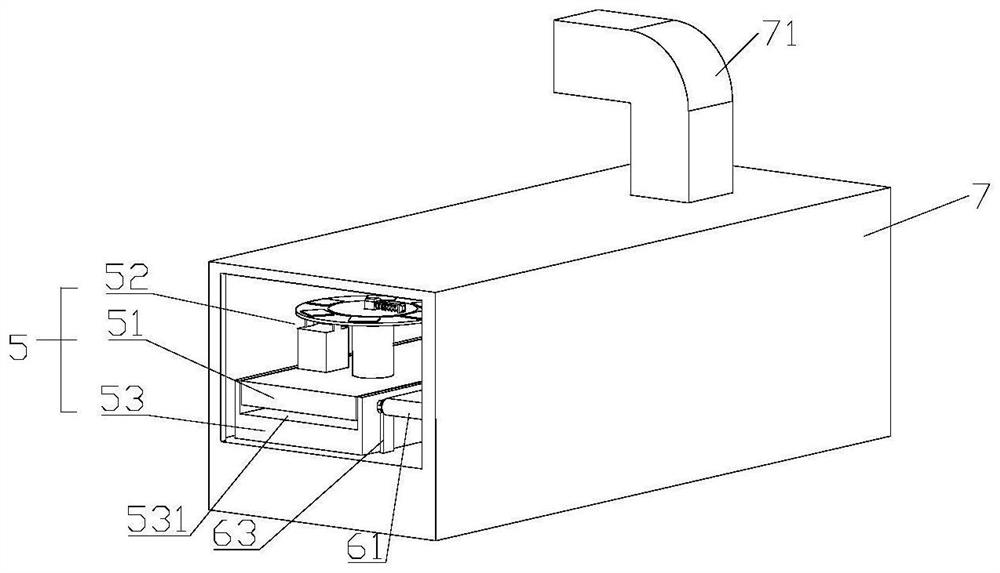

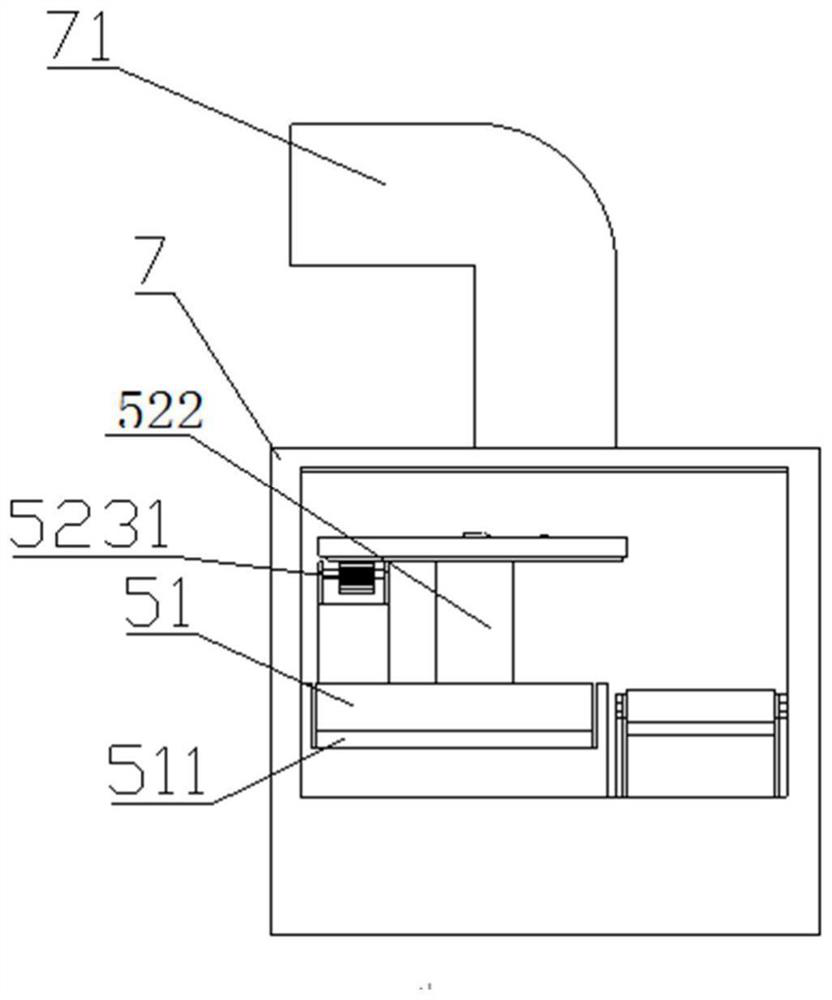

[0037] as Figures 2 through 6As shown, a wood dryer for drying the wood parts connected using the method described in Example 1, comprising a drying cadre 5, the drying cadre 5 comprising a mounting table 51, a drying table 52 and a base 53, the base 53 is provided above the chute 531, the mounting table 51 is disposed within the chute 531, the drying table 52 is fixed above the mounting table 51, the drying table 52 includes a drying plate 521, a support column 522 and a transmission 523, Support column 522 and transmission parts 523 are provided between the drying plate 521 and the mounting table 51, the bottom of the drying plate 521 is provided with a transmission groove 5211, the transmission 523 includes a transmission wheel 5231 that can be combined with the transmission groove 5211, the transmission part 523 is connected by the transmission wheel 5231 and the transmission groove 5211 and the drying plate 521 transmission, the drying plate 521 is set into a ring, the suppo...

Embodiment 3

[0043] The difference between the present embodiment and Example 2 is that: the drying tray 521 is provided with a sensor 5212 for detecting the moisture content of the wood.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com