Feeding and taking equipment for hardware electroplating

A technology for hardware and equipment, which is applied in the field of material loading and unloading equipment for hardware electroplating, which can solve the problems of messy overall screw angles, damage to the electroplating layer of screws, and reduced internal clamping area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

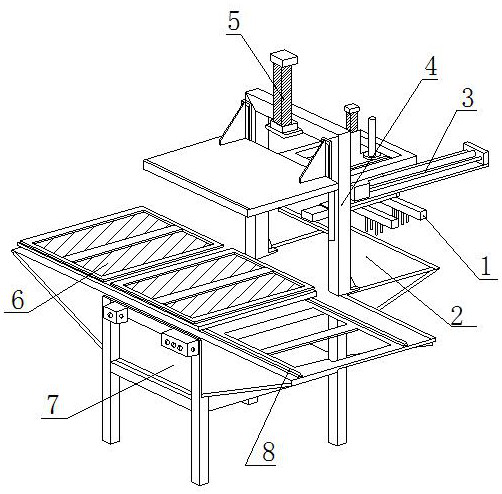

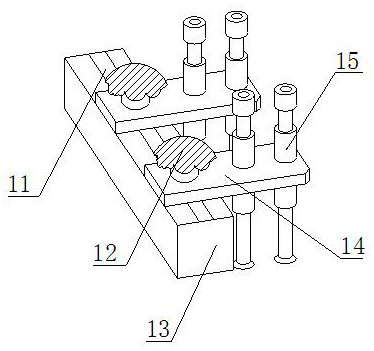

[0026] as attached figure 1 to attach Figure 5 Shown:

[0027] Its structure includes a suction frame 1, a stage 2, a slideway 3, a gantry frame 4, an air pump 5, a pick-up grid 6, a support seat 7, and a guide rail 8. The surface of the suction frame 1 and the slideway 3 are movable, and the The stage 2 is fixed on the upper surface of the support seat 7, and is embedded and connected with it, the gantry 4 is connected with bolts on both sides of the slideway 3, the air pump 5 is connected with the top of the gantry 4 with bolts, and the object picking grid 6 is fixed The upper end of the support seat 7 is clearance fit, the surface of the support seat 7 is embedded and connected with the guide rail 8, and the guide rail 8 is slidingly matched with the bottom end of the object picking grid 6. The suction frame 1 includes a positioning groove 11, an adjustment bolt 12, a frame Rod 13, fixed plate 14, absorbing roller 15, the inside of the positioning groove 11 is connected ...

Embodiment 2

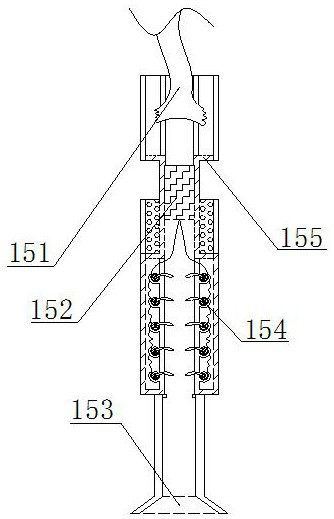

[0034] as attached Figure 6 to attach Figure 7 Shown:

[0035] Wherein, the storage opening 153 includes the inner wall b1 of the roller, the correction ring b2, the positioning rod b3, and the telescopic plate b4, the inner wall of the correction ring b2 is welded to the surface of the telescopic plate b4, and the positioning rod b3 is embedded and connected to the inner wall b1 of the roller , the inner wall b1 of the roller is embedded and connected with the expansion plate b4, and the correction ring b2 is movably matched with the outer wall of the positioning rod b3. Welding connection, wherein the correction ring b2 is conducive to swinging the sucked screw so that the big end is facing upwards, preventing the bottom from entering the interior of the device first.

[0036] Wherein, the correction ring b2 includes a rubber strip b21, a shrapnel b22, a slot b23, and a swing rod b24. The rubber strip b21 is in clearance fit with the top of the swing rod b24, and the sna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com