Synchronous lifting device and load driving device for bellows coupling

A technology of synchronous lifting and coupling, which is applied in the direction of lifting devices, lifting frames, etc., can solve the problems of heavy workload, inability to ensure the unchanged posture of the load rotating body, and waste of labor, so as to liberate the labor force, simplify the structure, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

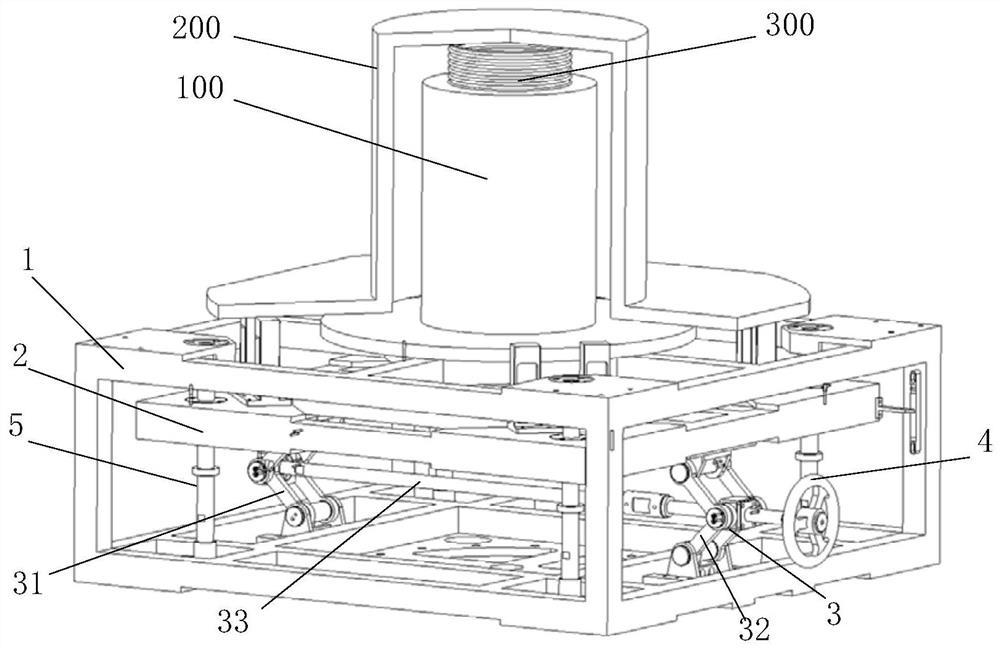

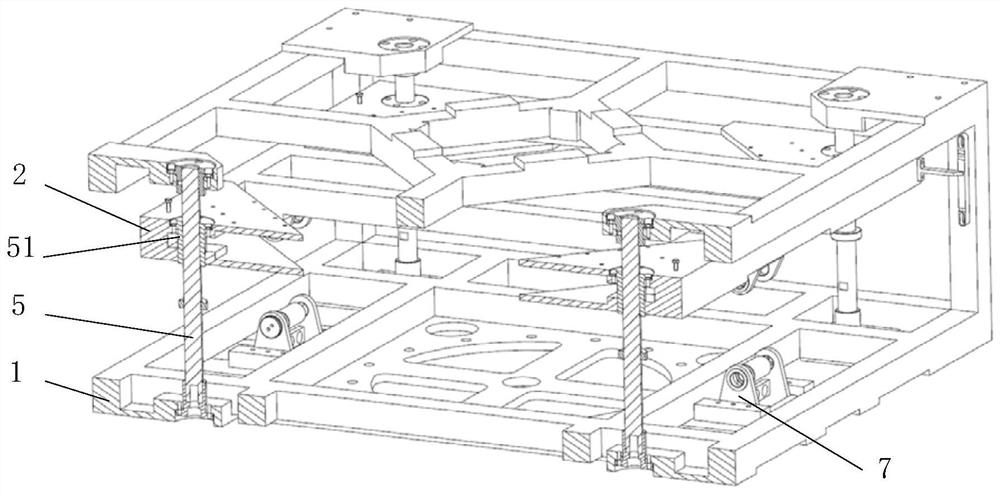

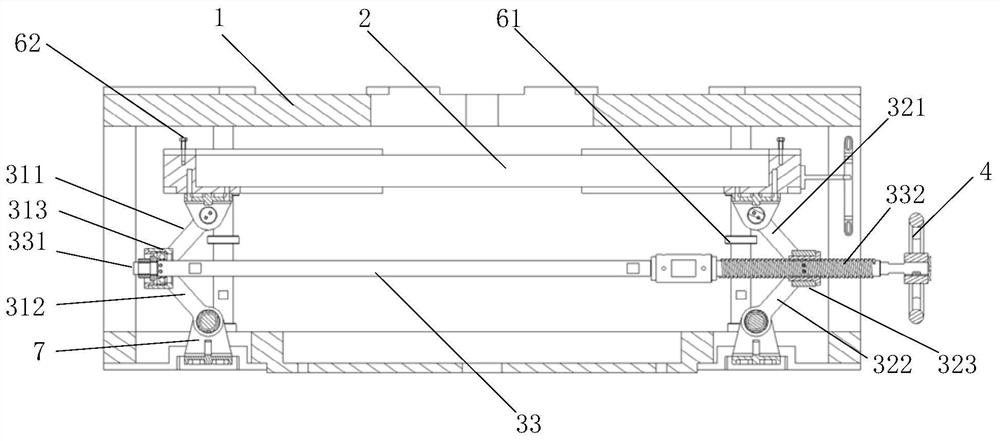

[0044] This embodiment provides a synchronous lifting device for a bellows coupling, see Figure 1-Figure 7 , the structural schematic diagram of the lifting device of this embodiment, the lifting device includes a frame 1, a load carrying mechanism 2, a link driving mechanism 3 and a manipulation mechanism 4: the frame 1 is used to install the load base 100, the frame 1 is a square frame, and the load base 100 is fixedly mounted on the top frame structure of the rack 1 . The load bearing mechanism 2 is a lifting plate for installing the load rotating body 200 . The load bearing mechanism 2 is arranged in the frame 1 and can rise and fall freely; the link drive mechanism 3 is arranged on the frame 1 and the load bearing mechanism 2 In between, one end of the connecting rod driving mechanism 3 is hinged on the bottom frame of the frame 1, and the other end of the connecting rod driving mechanism 3 is hinged under the load carrying mechanism 2; the operating mechanism 4 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com