Double-stage ultraviolet sterilization heat pool device and water heater

A thermal and ultraviolet technology, used in water heaters, fluid heaters, water/sewage treatment, etc., can solve problems such as poor adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] The present invention is further illustrated below by means of examples, but the present invention is not limited thereto within the scope of examples.

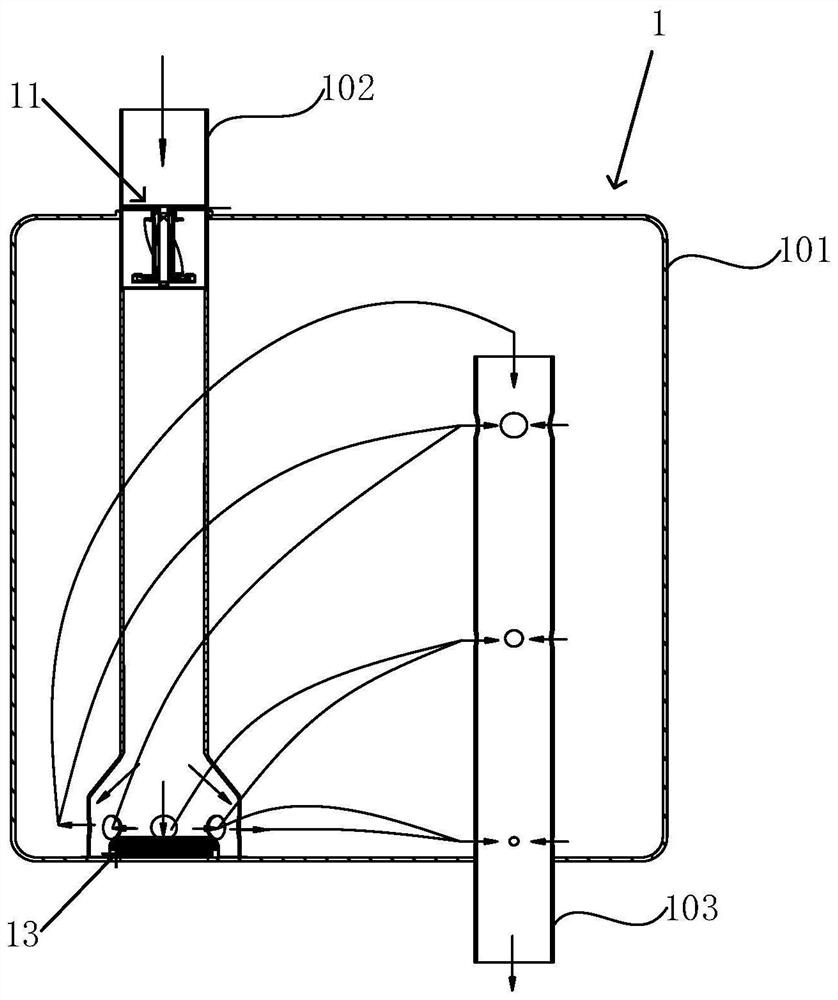

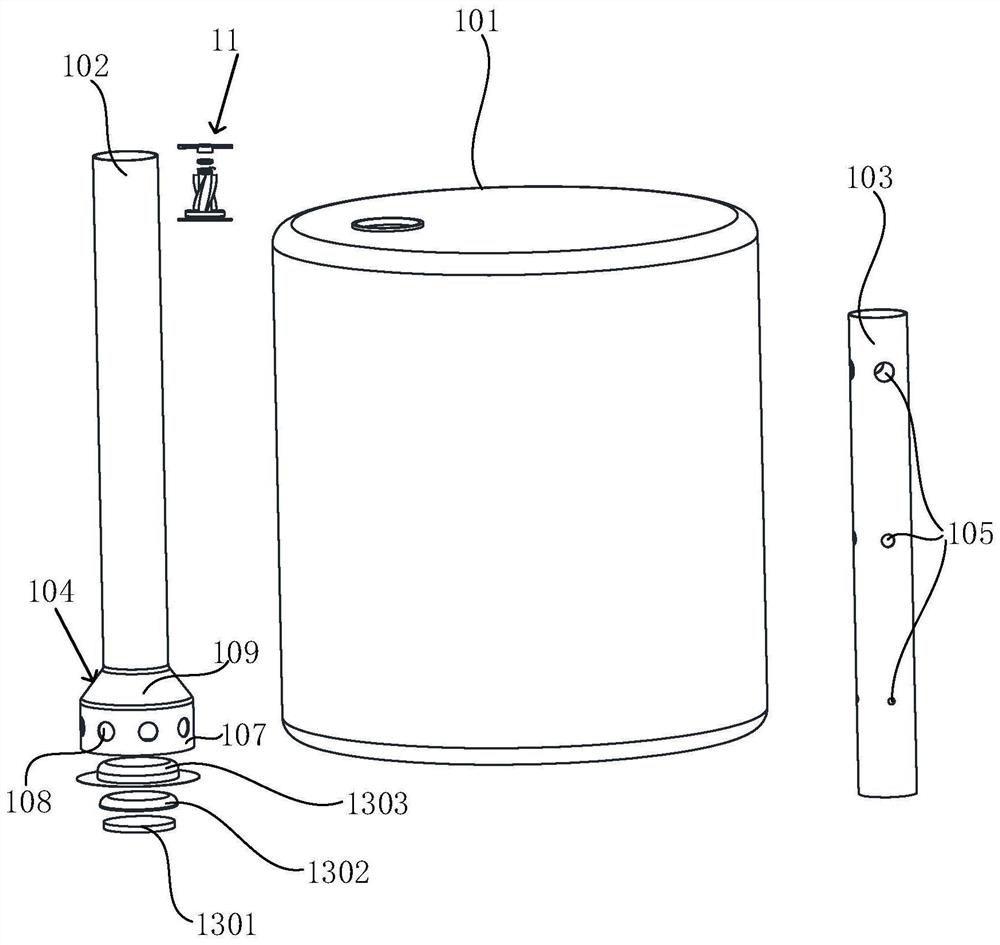

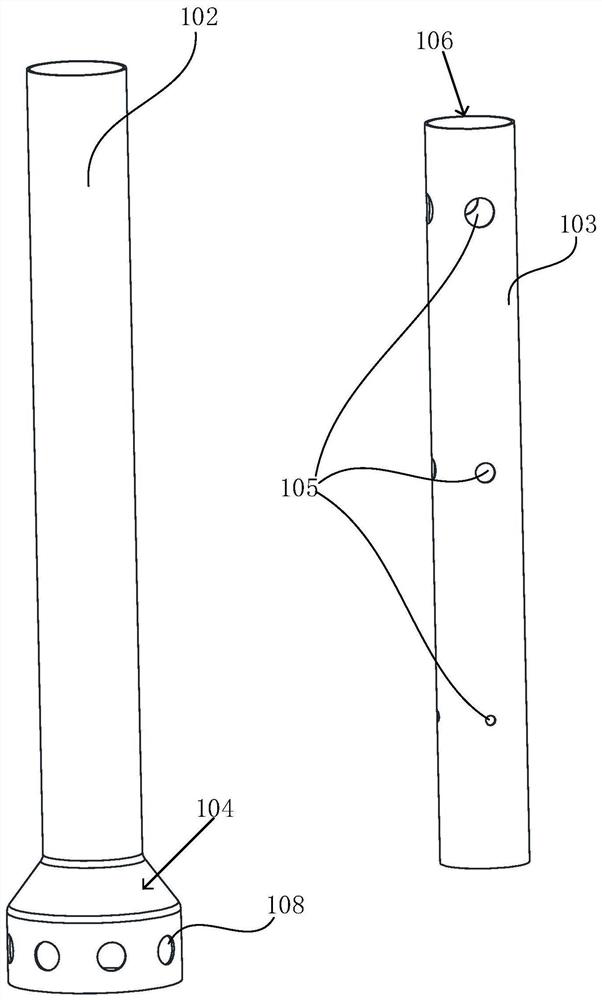

[0094] Such as figure 1 As shown, this embodiment discloses a dual-stage ultraviolet sterilizing thermal pool device 1, which includes a thermal pool inlet pipe 102 and a thermal pool housing 101, and the thermal pool inlet pipe 102 is fixedly connected to the thermal pool housing 101. The sterilizing thermal pool device 1 also includes a primary ultraviolet sterilizing component 11 and a secondary ultraviolet sterilizing component 13, the primary ultraviolet sterilizing component 11 and the secondary ultraviolet sterilizing component 13 are respectively arranged inside the thermal pool inlet pipe 102, and the primary ultraviolet sterilizing component 11 includes a spoiler component 1101, a first ultraviolet sterilization component 1102 and a speed measurement component 1103, the speed measurement component 1103 is ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com