Sampler capable of automatically adjusting sampling depth

An automatic adjustment and prototyping technology, applied in the direction of sampling devices, etc., can solve the problems of inflexible movement, high labor intensity, inconvenient use, etc., and achieve the effects of increasing overall assembly efficiency, increasing the upper and lower limits of height, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

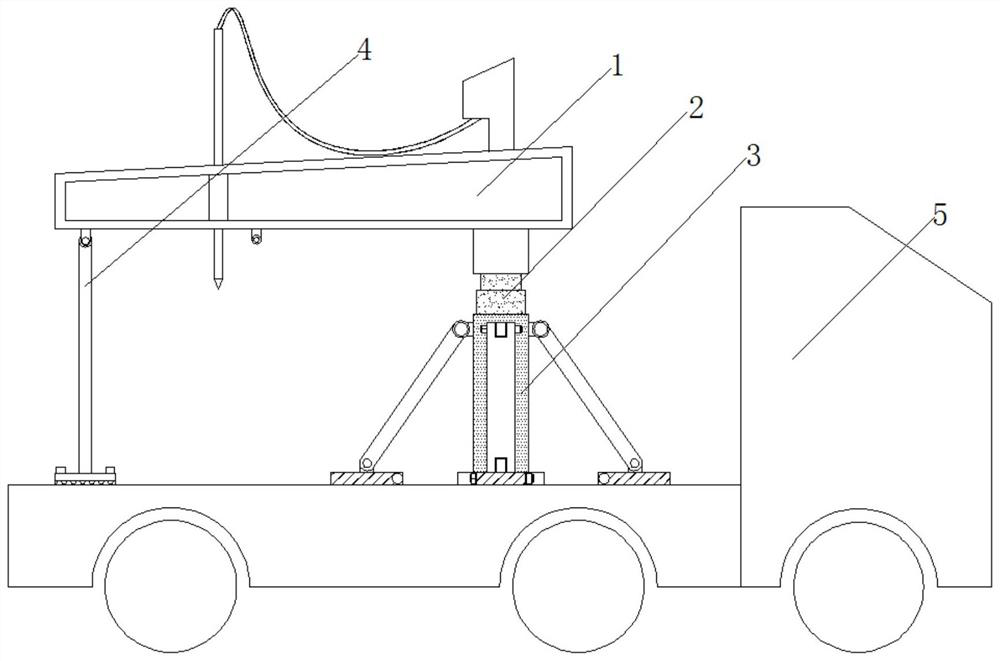

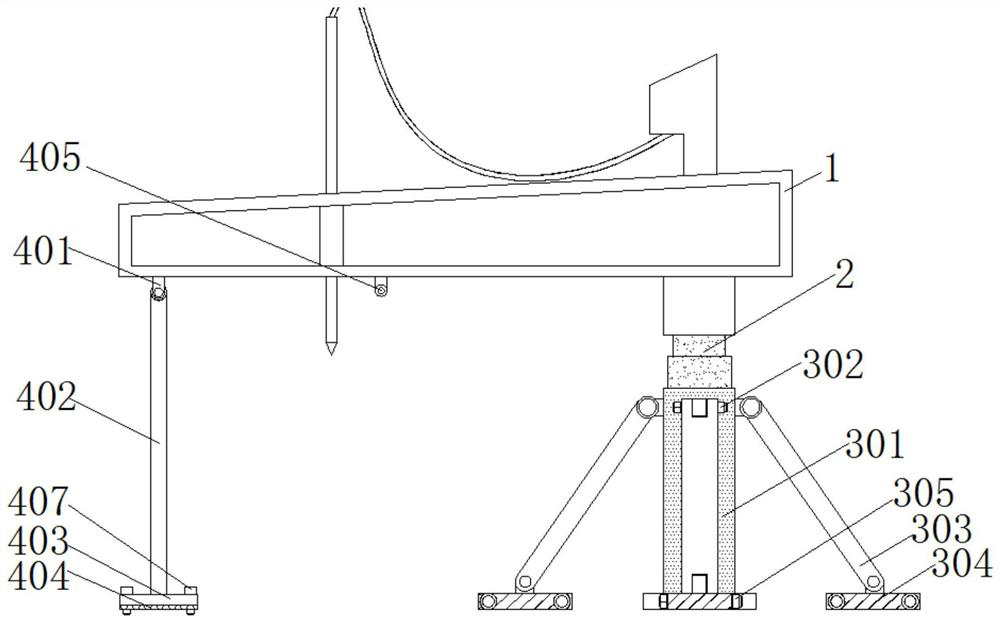

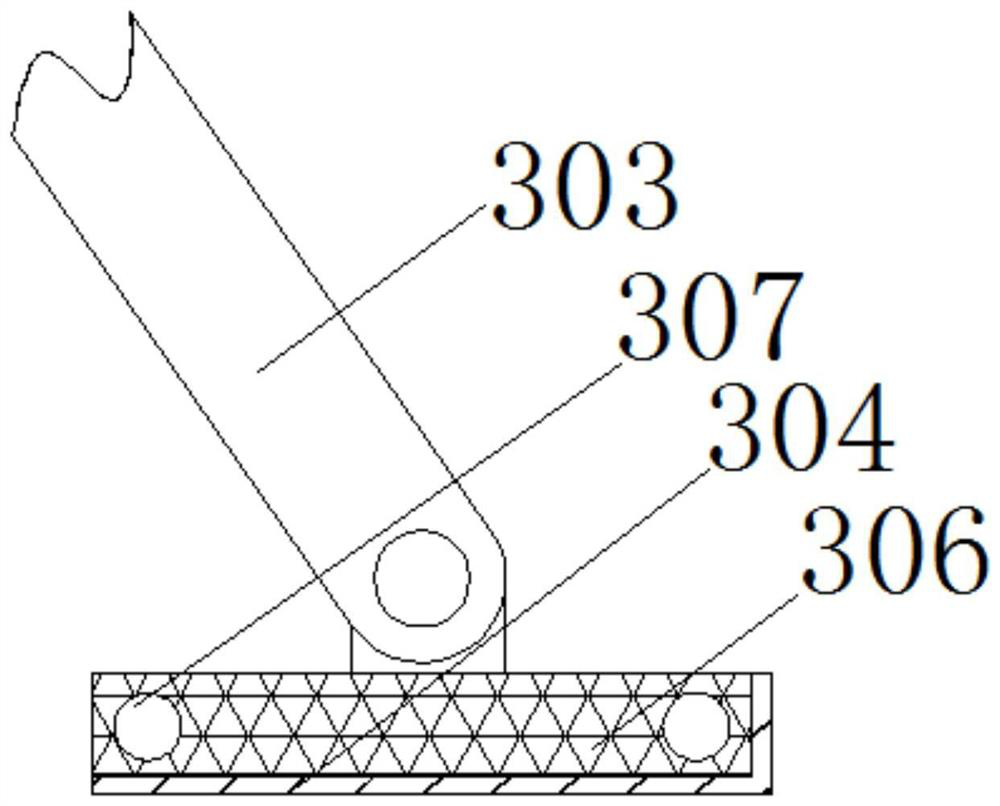

[0025] see Figure 1-4 , a cutting machine with automatic adjustment of cutting depth, comprising a cutting machine 1 and a flat motor vehicle 5, a first telescopic rod 2 is fixedly installed at the bottom of the right end of the cutting machine 1, and a support is arranged below the first telescopic rod 2 Mechanism 3, the support mechanism 3 includes a support column 301, a first bolt 302, a connecting rod 303, a sliding sleeve 304, a second bolt 305, a slider 306, a limit hole 307 and an adjustment hole 308; the bottom of the first telescopic rod 2 is fixed A support column 301 is installed, and the top of the support column 301 is provided with a connecting rod 303. The connecting rod 303 has four groups and is evenly distributed on the top of the support column 301. The top of the connecting rod 303 rotates with the top of the support column 301 through the first bolt 302. Connection, the bottom end of the connecting rod 303 is connected with the slider 306 through the rot...

Embodiment 2

[0028] see figure 1 , 2 , 5 and Image 6 , the cutting machine with automatic adjustment of the cutting depth, the left side of the cutting machine 1 is provided with an auxiliary balance mechanism 4, the auxiliary balance mechanism 4 includes a connecting piece 401, a bracket 402, a fixed plate 403, an anti-skid rubber pad 404, a second telescopic Rod 405, slot 406 and pin 407; the bottom of the left end of the cutting machine 1 is fixedly connected with a connecting piece 401, the bottom of the connecting piece 401 is rotatably connected with a bracket 402, the bottom of the bracket 402 is fixedly connected with a fixed plate 403, and the fixed plate 403 The bottom of the bottom is fixedly connected with a non-slip rubber pad 404; the lower left side of the cutting machine 1 is fixedly equipped with a second telescopic rod 405, and the front end of the second telescopic rod 405 is provided with a card slot 406. The interior of the left and right ends of the fixed plate 403...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com