Anti-overheating cable

A technology to prevent overheating and cables, applied in the direction of insulated cables, flat/ribbon cables, cables, etc., can solve problems such as spontaneous combustion, damage to life and property safety, etc., to avoid excessive heat accumulation, achieve heat transfer, and rapid heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

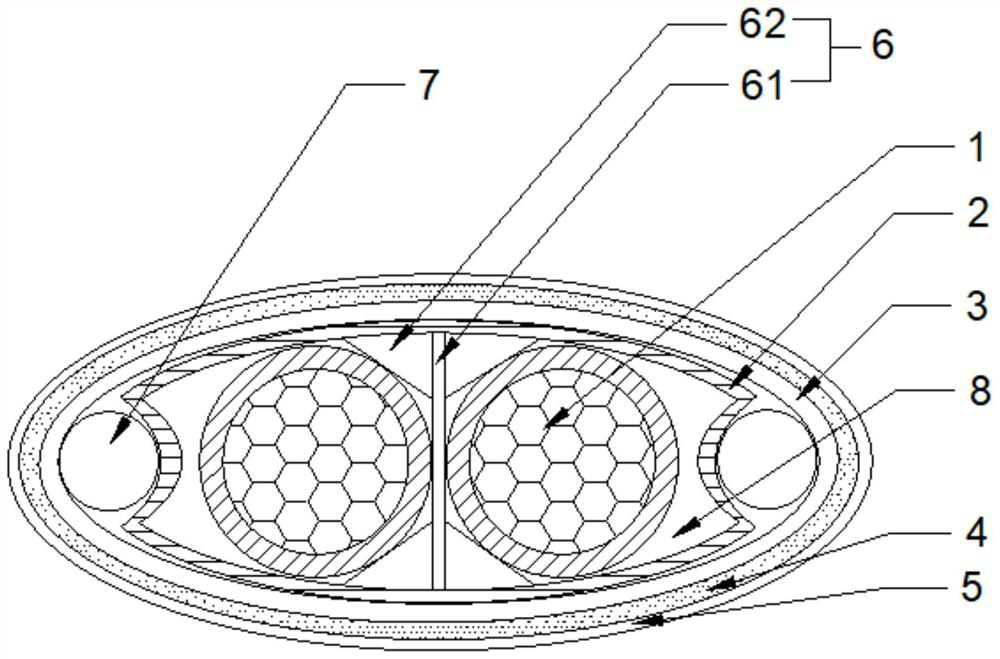

[0029] like figure 1 and 2 The anti-overheating cable shown includes: several cable cores 1 arranged side by side, and an inner lining layer 2, an outer insulating layer 3, a metal strip heat conducting layer 4 and an abrasion-resistant sheath layer 5 coated on the outer periphery of each cable core 1 in sequence;

[0030] An elliptical cavity is arranged inside the outer insulating layer 3, and an endothermic expansion strip 7 is arranged between the outer insulating layer 3 and the inner lining layer 2. The inner liner 2 is extruded so that the inner liner 2 forms an arc-shaped depression, the inner liner 2 is made of elastic material, and the inner liner 2 is provided with several holes at least in the arc-shaped depression, and the heat-absorbing expansion strip 7 passes through the thermal expansion control hole bit opening.

[0031] As a preference of the above-mentioned embodiment, a support frame 6 is arranged in the inner lining layer 2 to support the local position...

Embodiment 2

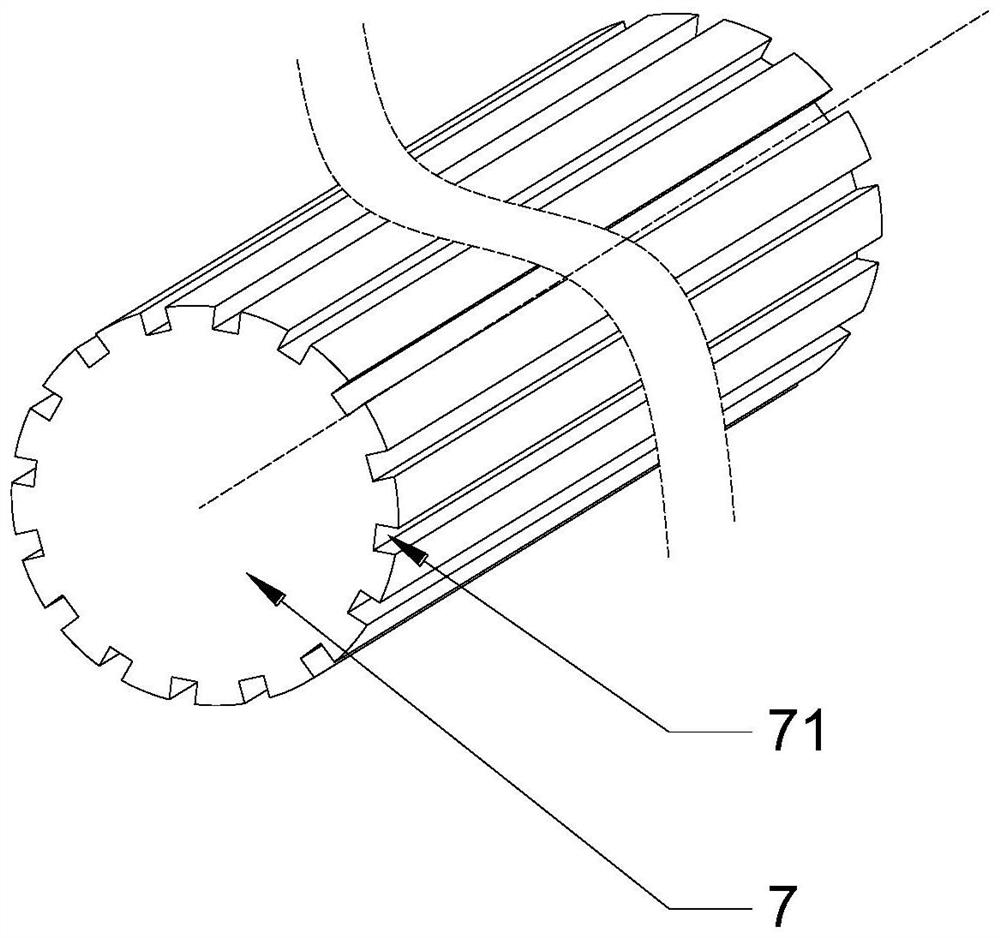

[0037] like image 3 As shown, the difference from Embodiment 1 is that the circumferential surface of the heat-absorbing expansion strip 7 is equidistantly provided with several protrusions 72 equal in length to the heat-absorbing expansion strip 7 , and heat dissipation channels are formed between two adjacent protrusions 72 . Reduce the number of heat dissipation layers.

Embodiment 3

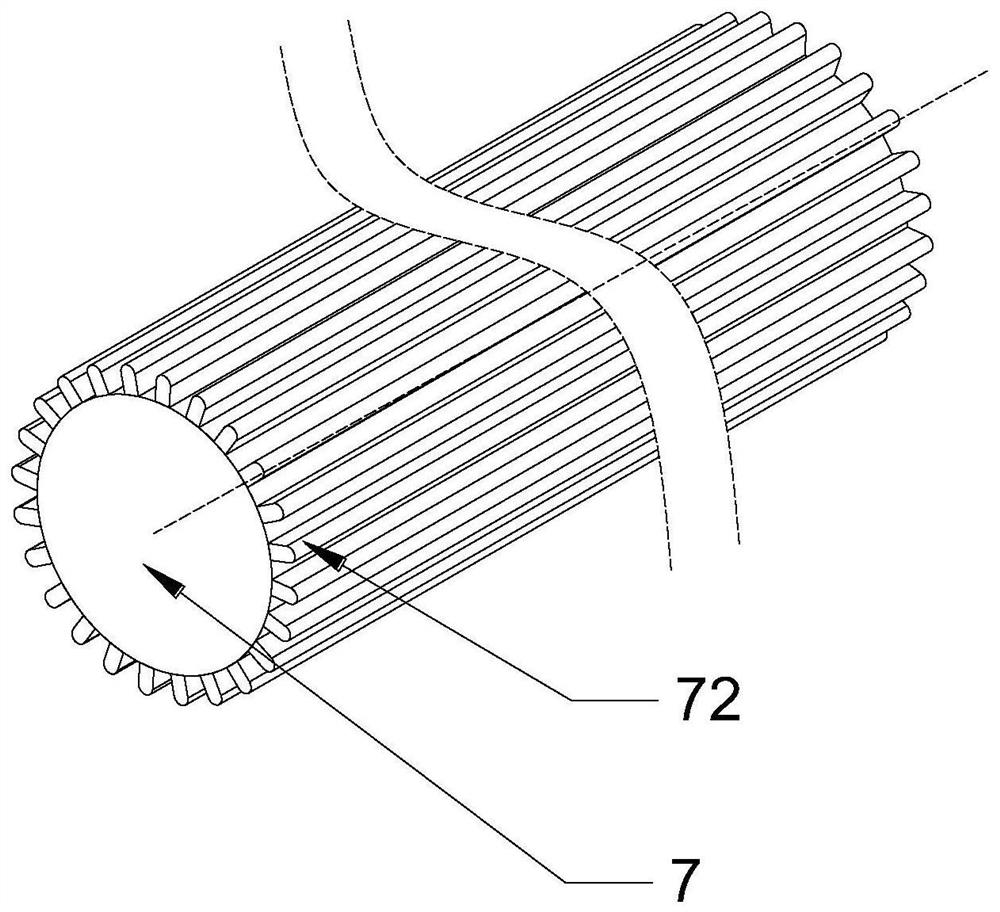

[0039] like Figure 4 As shown, the difference from the first embodiment is that the circumferential surface of the heat-absorbing expansion strip 7 is provided with a spiral groove 73, and the spiral groove 73 is used to form a heat dissipation channel and reduce the number of heat dissipation layers.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap