An electric welding machine with good heat dissipation

A heat dissipation, electric welding machine technology, applied in the direction of welding equipment, manufacturing tools, auxiliary welding equipment, etc., can solve the problems of air pollution, shortened service life of electric welding machines, poor heat dissipation performance, etc., to solve the problem of dust collection and purification, avoid using The effect of shortening the life and improving the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

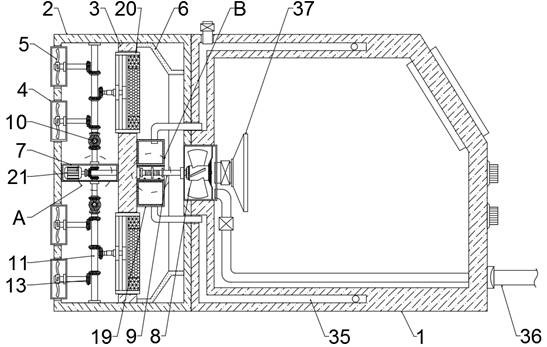

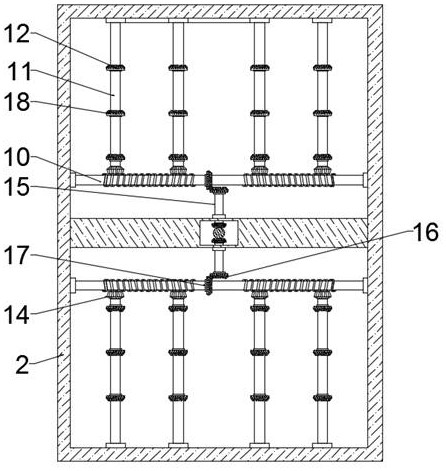

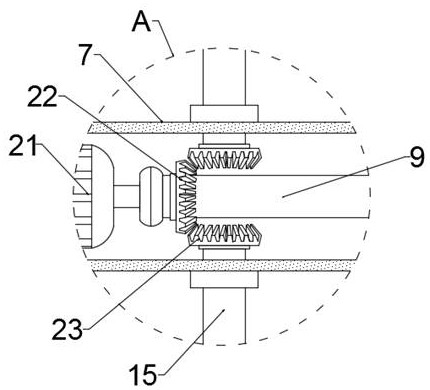

[0030] Embodiment 1: see Figure 1-9, an electric welding machine with good heat dissipation, including a welding box 1, a linkage mechanism, a driving component, a transmission component, a filtering mechanism and an induction component, and a cooling box 2 is fixed on one side of the welding box 1. A fixed plate 3 is fixed vertically, a number of installation openings are evenly opened on one side of the heat dissipation box 2, and a fan frame 4 is installed in each installation opening, and an inner wall of one side of each fan frame 4 is provided with air intake fan blades 5; a partition plate 7 is fixed horizontally between the middle part of the inner wall of the heat dissipation box 2 and the fixed plate 3, a drive cavity is opened in the partition plate 7, the drive assembly is arranged in the drive cavity, and one side of the heat dissipation box 2 The upper and lower parts are provided with linkage mechanisms; the top and bottom surfaces of the partition plate 7 are ...

Embodiment 2

[0035] Embodiment 2: In this embodiment, the present invention also proposes a method for using an electric welding machine with good heat dissipation, including the following steps:

[0036] Step 1: First, the electrical components in the welding box 1 are installed, and then the motor 21, the electric push rod 31, the first sensor 38 and the second sensor 39 are electrically connected to the controller in the welding box 1, respectively. Then the controller is electrically connected with the external power supply; then the cooling liquid is easily injected into the annular box 19 through the cooling cavity 35 through the liquid injection pipe, until the cooling liquid fills the annular box 19;

[0037] Step 2, when it is necessary to dissipate heat inside the welding box 1, the rotating shaft 9 is driven to rotate by the controlled motor 21, and the sixth bevel tooth 22 is easily driven to rotate through the rotation of the rotating shaft 9. The meshing transmission of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com