A composite rust inhibitor for reinforced concrete based on natural gluten

A technology of reinforced concrete and gluten is applied in the field of reinforced concrete composite rust inhibitor, which can solve the problem of high cost and achieve the effects of inhibiting corrosion of steel bars and improving durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

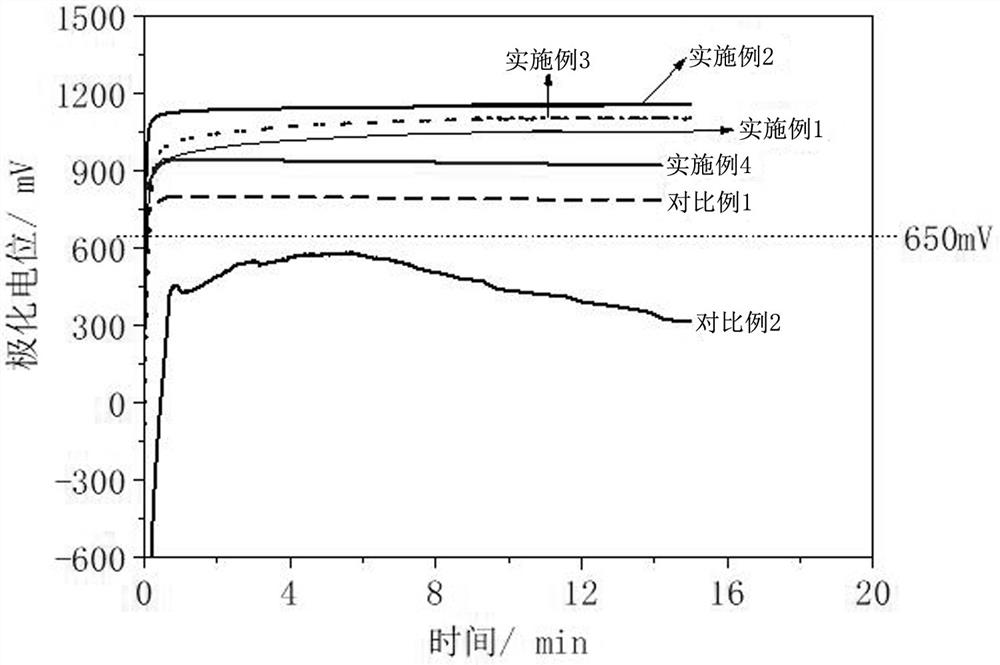

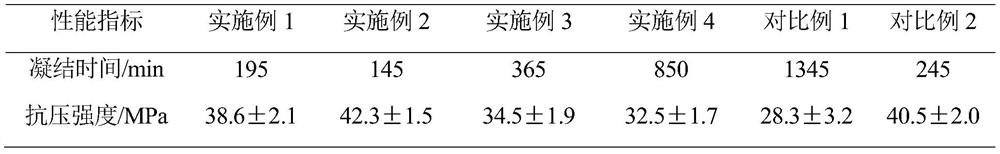

[0022] First, mix 3g of alkali-soluble glutenin with 5g of silica fume and 1.5g of calcium sulfate in a mortar to obtain a composite rust inhibitor; secondly, mix the composite rust inhibitor with 95g of cement and 300g of sand in a mixing pot After dry mixing evenly, introduce 60g of tap water containing 1.66g of sodium chloride and wet mix for 2 minutes, pour the prepared mortar into three cylindrical specimens and three cubic specimens. After being molded for 24 hours, it will be removed from the mold, and it will be raised until 28 days before use.

Embodiment 2

[0024] Firstly, mix 2.5g of alkali-soluble glutenin, 5g of silica fume and 0.02g of triethanolamine in an agate mortar and use it as a composite rust inhibitor, then dry mix it with 95g of cement and 300g of sand in a stirring pot, and then Introduce 60g of tap water containing 1.66g of sodium chloride and wet mix for 2 minutes, pour the mixed mortar into three cylindrical specimens and three cubic specimens, and standardize for 28 days for use.

Embodiment 3

[0026] First, mix 2.5g of alkali-soluble glutenin, 10g of finely ground slag and 3g of calcium nitrate in an agate mortar to make a composite rust inhibitor, and then dry mix it with 90g of cement and 300g of sand in a stirring pot, and then Introduce 60g of tap water containing 1.66g of sodium chloride and wet mix for 2 minutes, and pour the mixed mortar into three cylindrical specimens and three cubic specimens each. After 24 hours of molding, it is demoulded, and it is standard-raised until 28 days before use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com