Connecting structure of waist beam and support pile and construction method of connecting structure

A technology for connecting structures and construction methods, applied in basic structure engineering, excavation, construction, etc., can solve problems such as difficulty in connecting waist beams and supporting piles, damage, etc., to improve construction quality and construction efficiency, and ensure overall stability. Easy and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

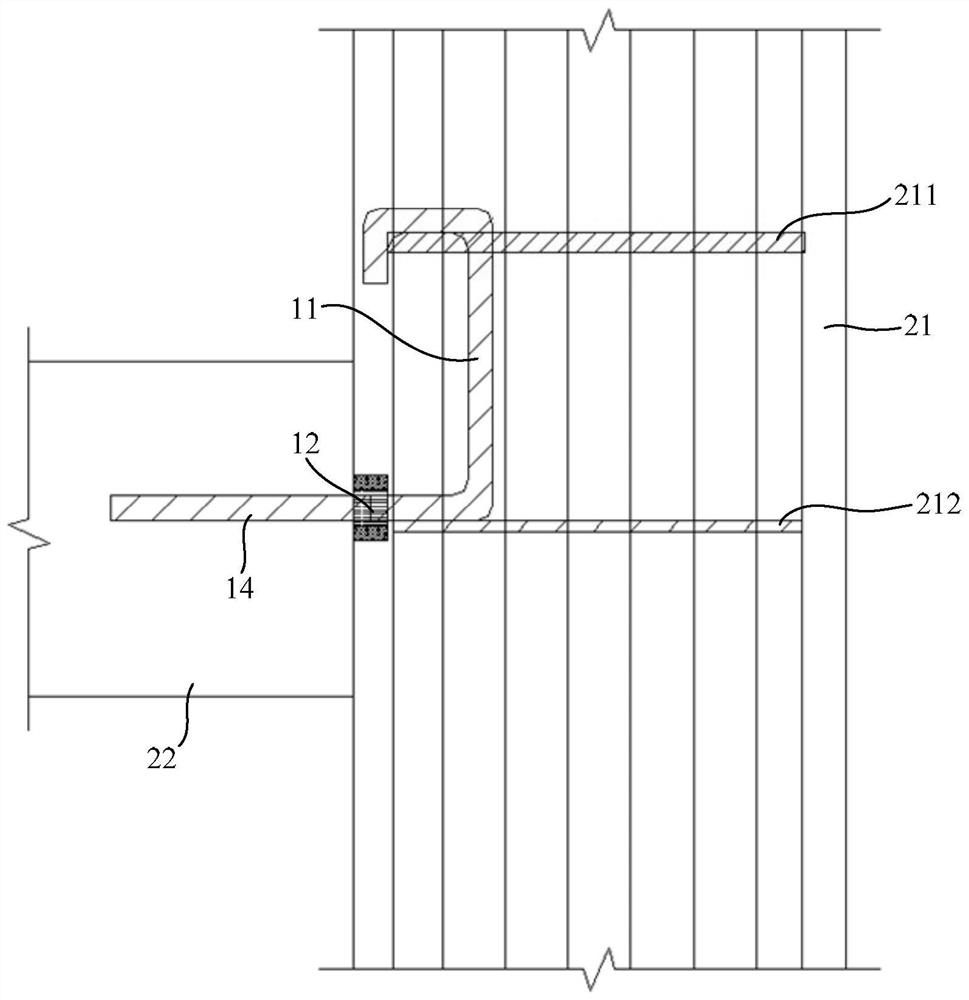

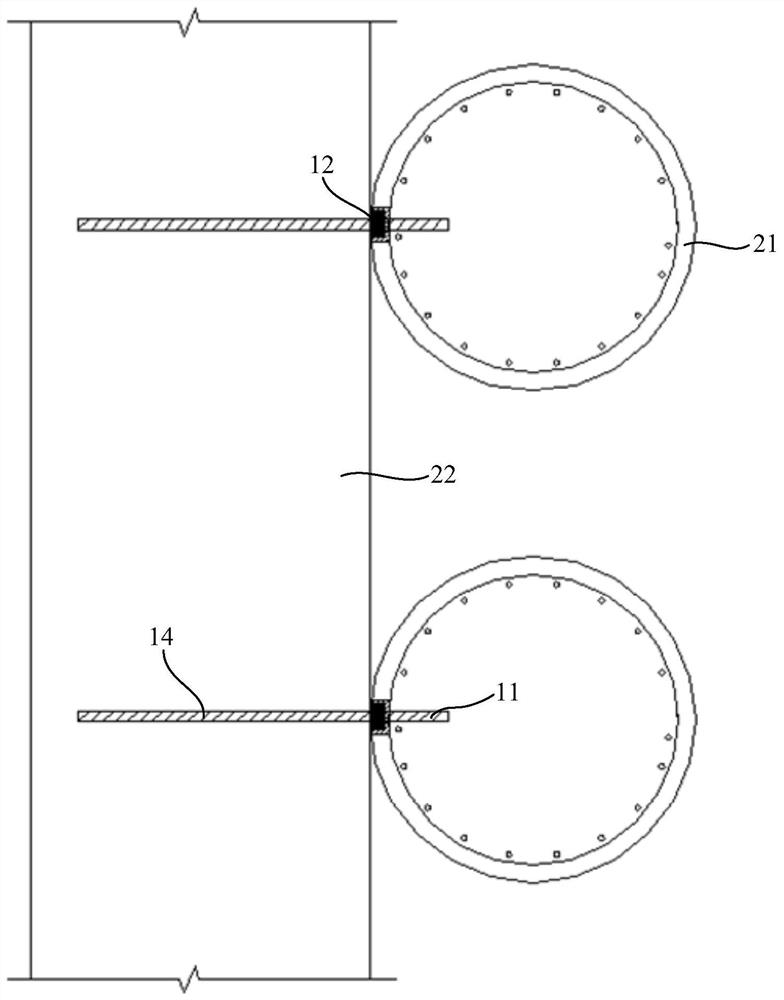

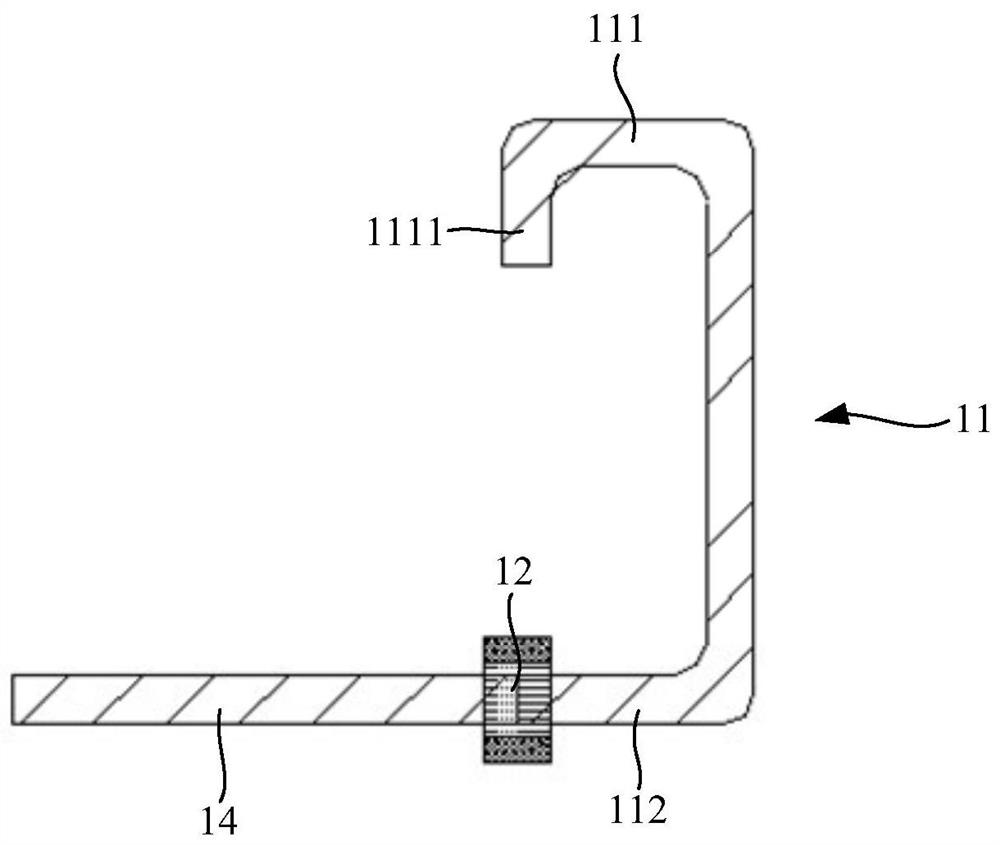

[0045] The specific embodiment of the connection structure of waist beam of the present invention and support pile is as follows:

[0046] After excavating and forming pile holes, before lowering the reinforcement cage, the embedded parts are installed in the reinforcement cage, that is, the bending part 1111 of the embedded reinforcement 11 hooks the stiffening hoop 211 of the reinforcement cage, and the bending part 1111 and the fixing part 111 are connected with each other. The stiffening hoop 211 is welded and connected, and the insertion part 112 is welded and connected to the corresponding spiral hoop 212. At this time, the end of the insertion part 112 protrudes slightly from the reinforcement cage;

[0047] The sleeve 12 is screwed on the end of the socket part 112, and the sleeve 12 partially protrudes from the end of the socket part 112, and the sealing plug 121 is inserted into the protruding end of the sleeve 12, and the sealing plug 121 is pulled The ring 1211 fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com