Road paving structure based on municipal engineering

An engineering and road technology, which is applied in the field of road paving structures based on municipal engineering, can solve problems such as poor butt joint of pipe openings, difficulty in fixing circular pipes, and poor quality of joints, etc., to achieve firm fixation, easy connection, The effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

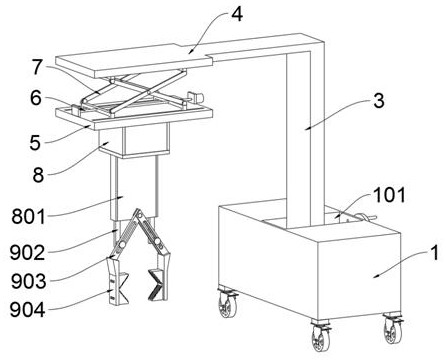

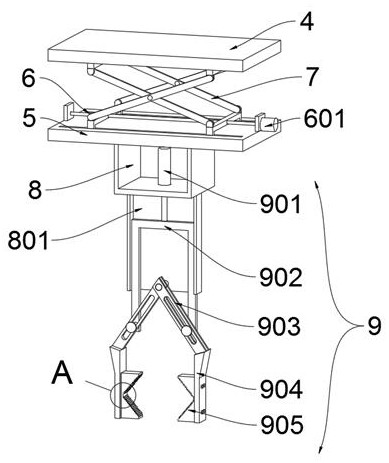

[0030] as attached figure 1 to attach Figure 6 Shown:

[0031] The present invention provides a road paving structure based on municipal engineering, comprising a vehicle body 1 and a scissor arm 7; In the chute; one side of the top of the support column 3 is provided with a fixed horizontal plate 4, and the upper connecting rod 401 is symmetrically provided with two groups and is slidably clamped in the chute on the lower surface of the fixed horizontal plate 4; The connecting rod 401 is hinged, and the lower end of the scissor arm 7 is hinged with the lower connecting rod 502. The lower connecting rod 502 is symmetrically provided with two groups and is slidingly clamped in the chute on the upper surface of the sliding base plate 5; Fixedly connected, and the lower end of the protective shell 8 is provided with a track box 801;

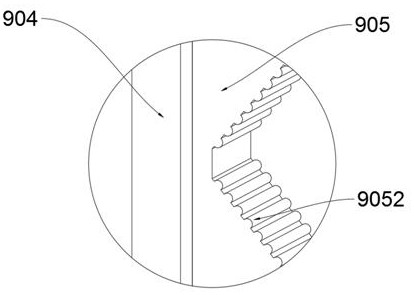

[0032] Wherein, the clamping device 9 includes an electric cylinder 901, a U-shaped frame 902, a rotating rod 903 and a clamping plate 904, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com