Assembly type concrete building connecting structure

A technology for concrete construction and connection structure, which is applied in the construction of buildings, construction, and the processing of building materials, etc., can solve problems such as weak connection of concrete buildings, and achieve the effect of simple and convenient fixing method, improving seismic performance, and simple and convenient fixing method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

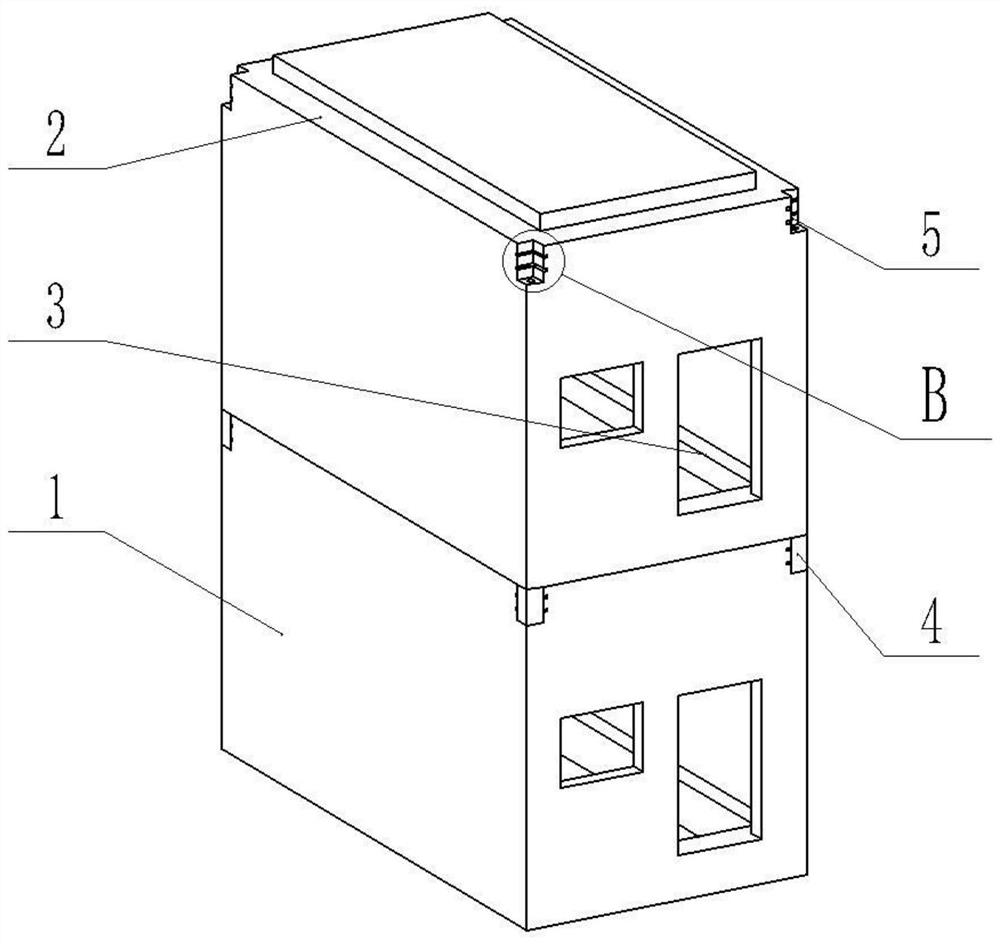

[0033] A prefabricated concrete building connection structure, combined with figure 1 , including the building body 1, and the building body 1 is stacked and connected sequentially from bottom to top. The upper end of the building body 1 is provided with a circle of step-shaped step grooves 2 along the circumference, and the bottom of the building body 1 is provided with an annular inner edge protrusion 3 matching with the step groove 2, and the inner four corners of the building body 1 are integrally formed with four 17 square seats.

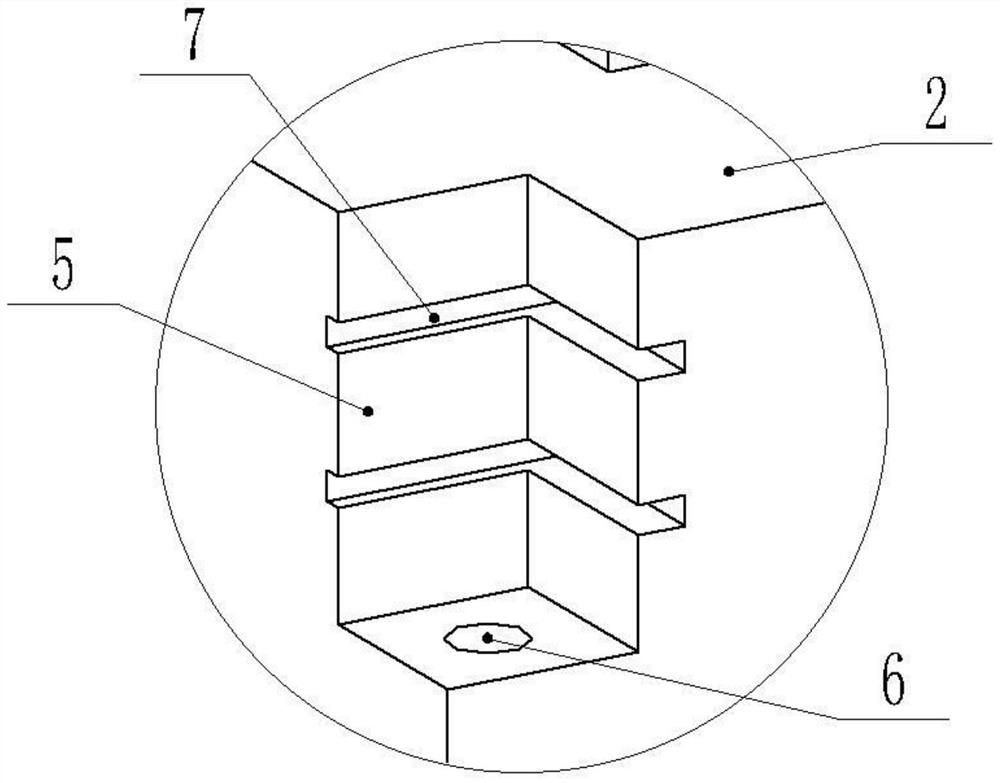

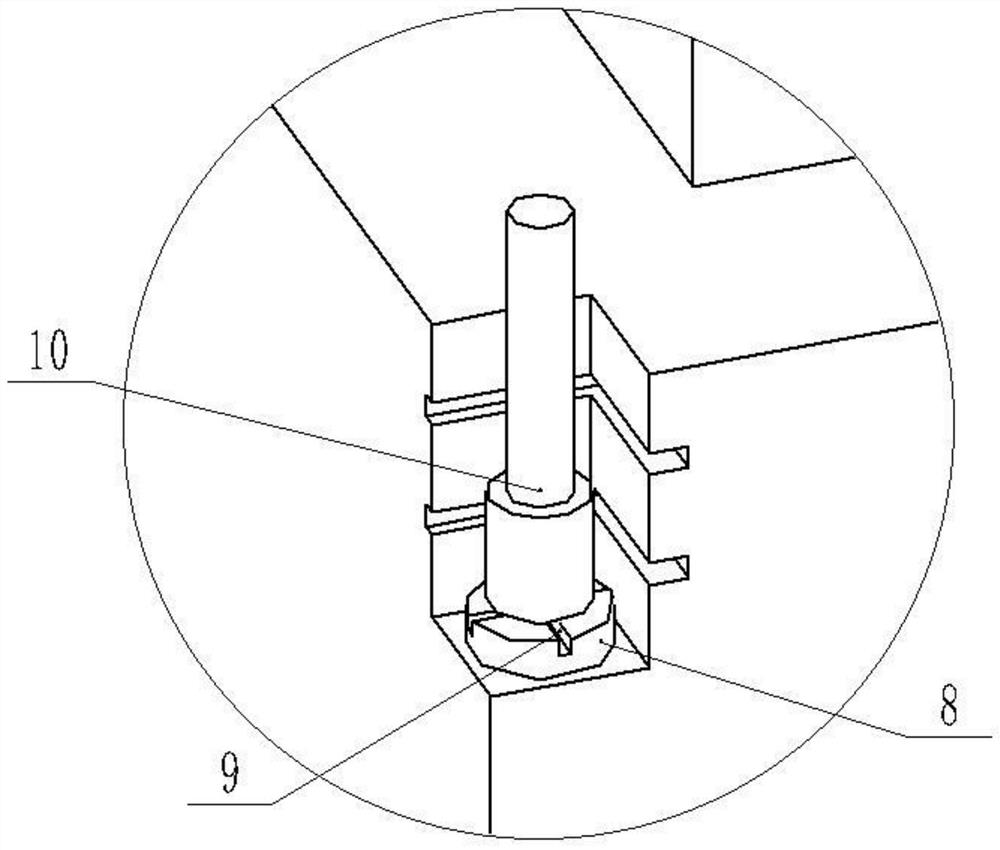

[0034] combine Figure 2-Figure 5 , the four corners of the step groove 2 are vertically provided with mounting grooves 5, and the mounting grooves 5 extend into the square seat 17 but do not completely penetrate the square seat 17. The center of the bottom of the installation groove 5 is provided with a first screw hole 6, and the first screw hole 6 extends into the square seat 17, and the two inner sidewalls of the first screw hole 6 are ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com