Compaction device for compacting moulded bodies from granular substances and method thereof

A compaction device, a technology for granular materials, applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of increased mechanical load, energy loss, large mechanical load, etc., and achieve high vibration frequency and reproducibility. High, quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

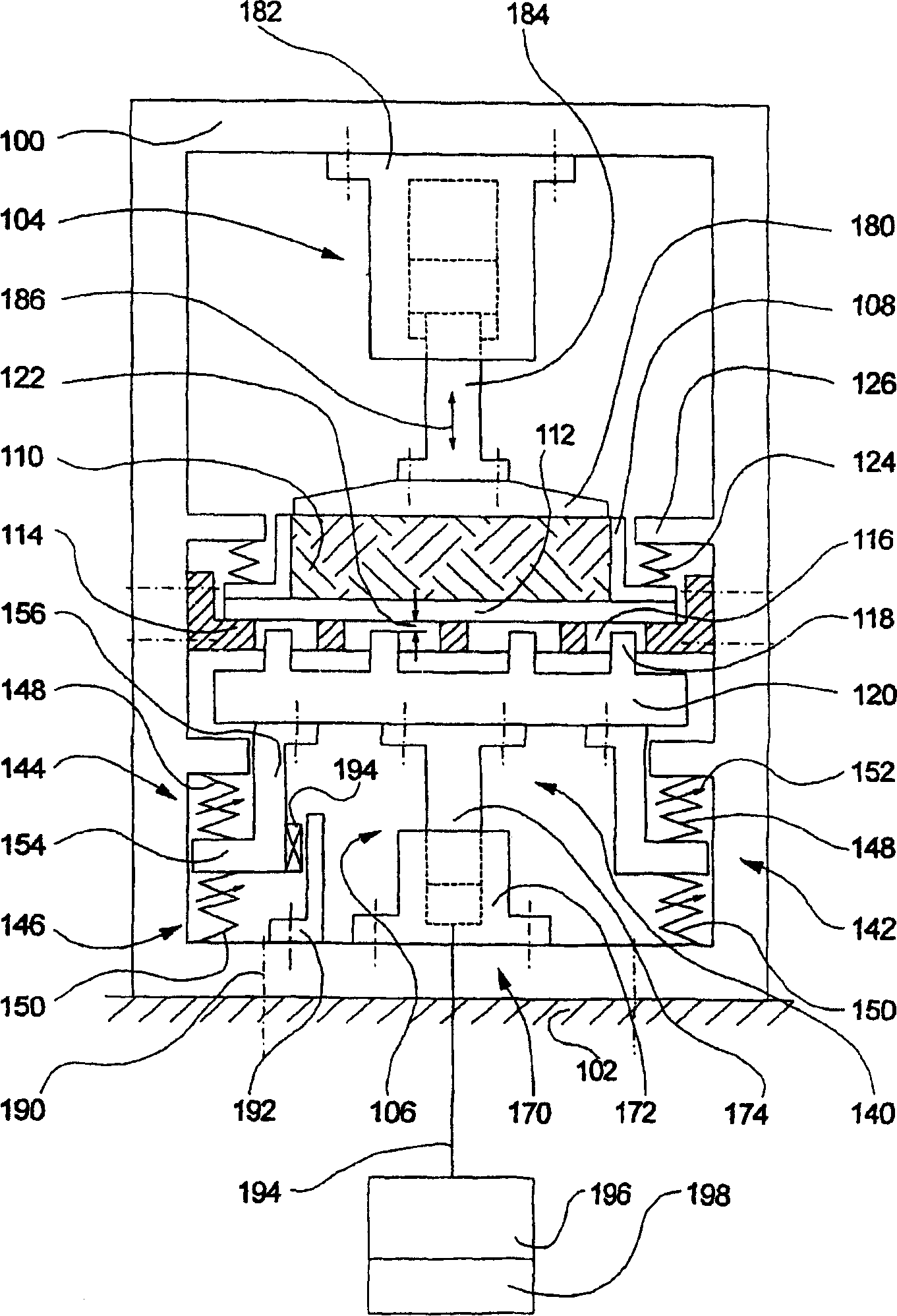

[0035] figure 1 Among them, reference numeral 100 denotes the frame of the compacting device standing on the base 102, through which the forces transmitted from the compressing device 104 and from the vibrator device 106 are mutually supported. In this case, the frame is firmly connected to the base by a connection indicated by line 190 . When the mass of the frame is small, the exciting force transmitted to the base is quite large. The lower end of the molded body 110 enclosed in the molding cavity of the molding box 108 is placed on the pallet 112 . The pallet rests on a bar 114 which is secured to the frame 100 (hatched for clarity) with a gap 116 . The impact rod 118 of the vibrating table 120 can pass through this gap and impact the underside of the pallet after overcoming the air gap 122 during the vibrating motion of the vibrating table. The molding box 108 placed on the pallet is firmly pressed against the upper surface of the pallet 112 by the spring 124 supported...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com