Eddy current axial damper

A damper, eddy current technology, applied in springs/shock absorbers, springs, magnetic springs, etc., can solve the problems of size interference, enlarged magnet frame size, difficulties in design, production and assembly, and reduce the cost of life. , The effect of reducing the whole life cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

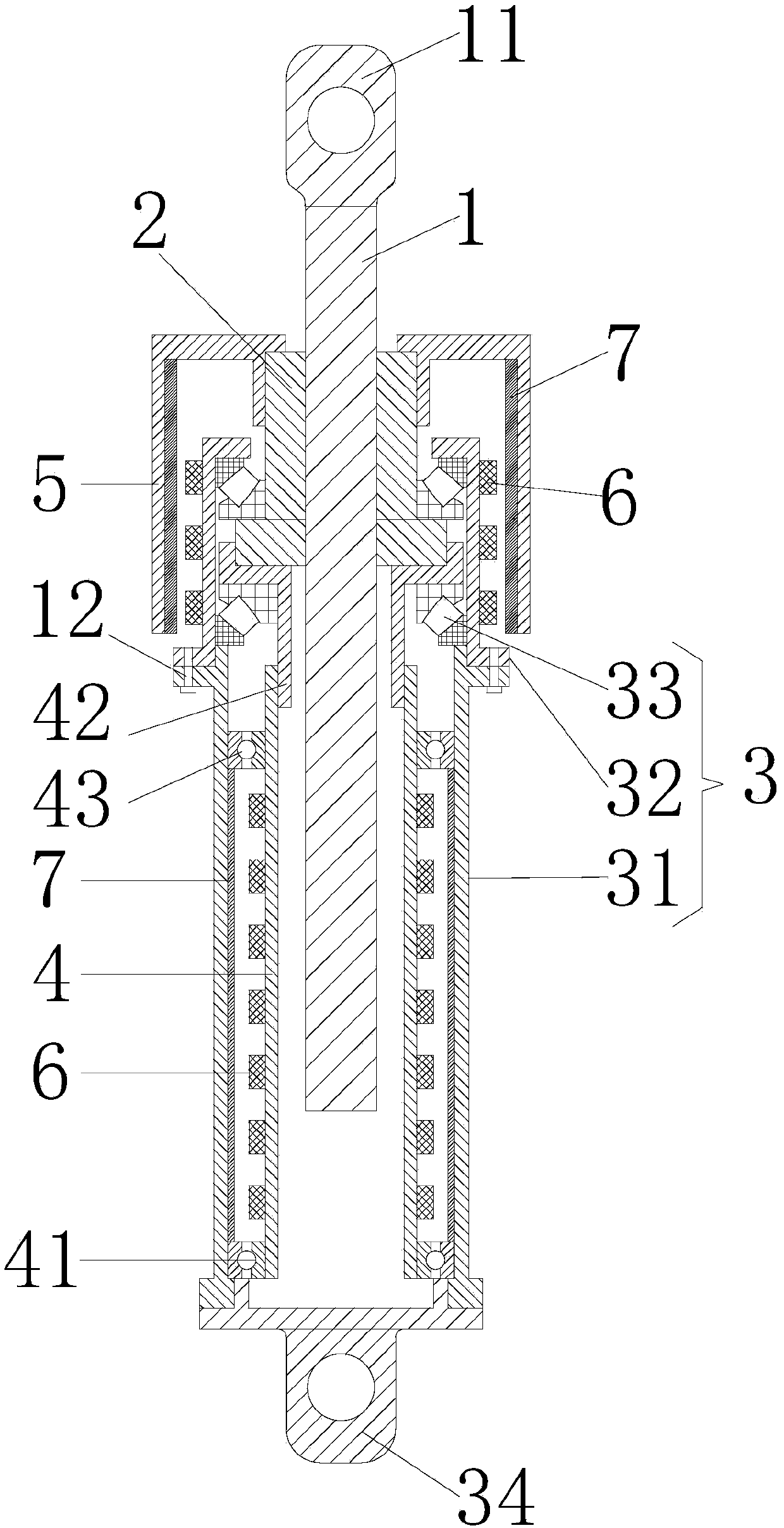

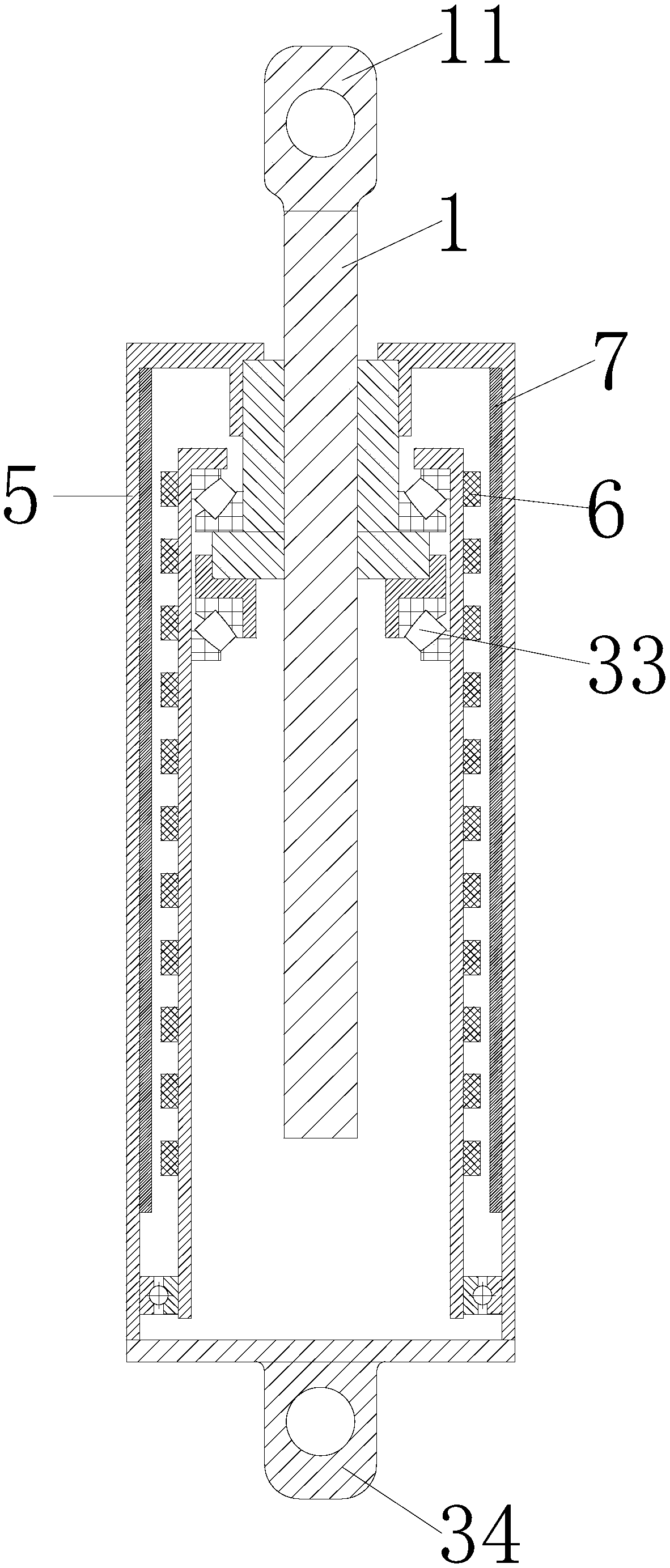

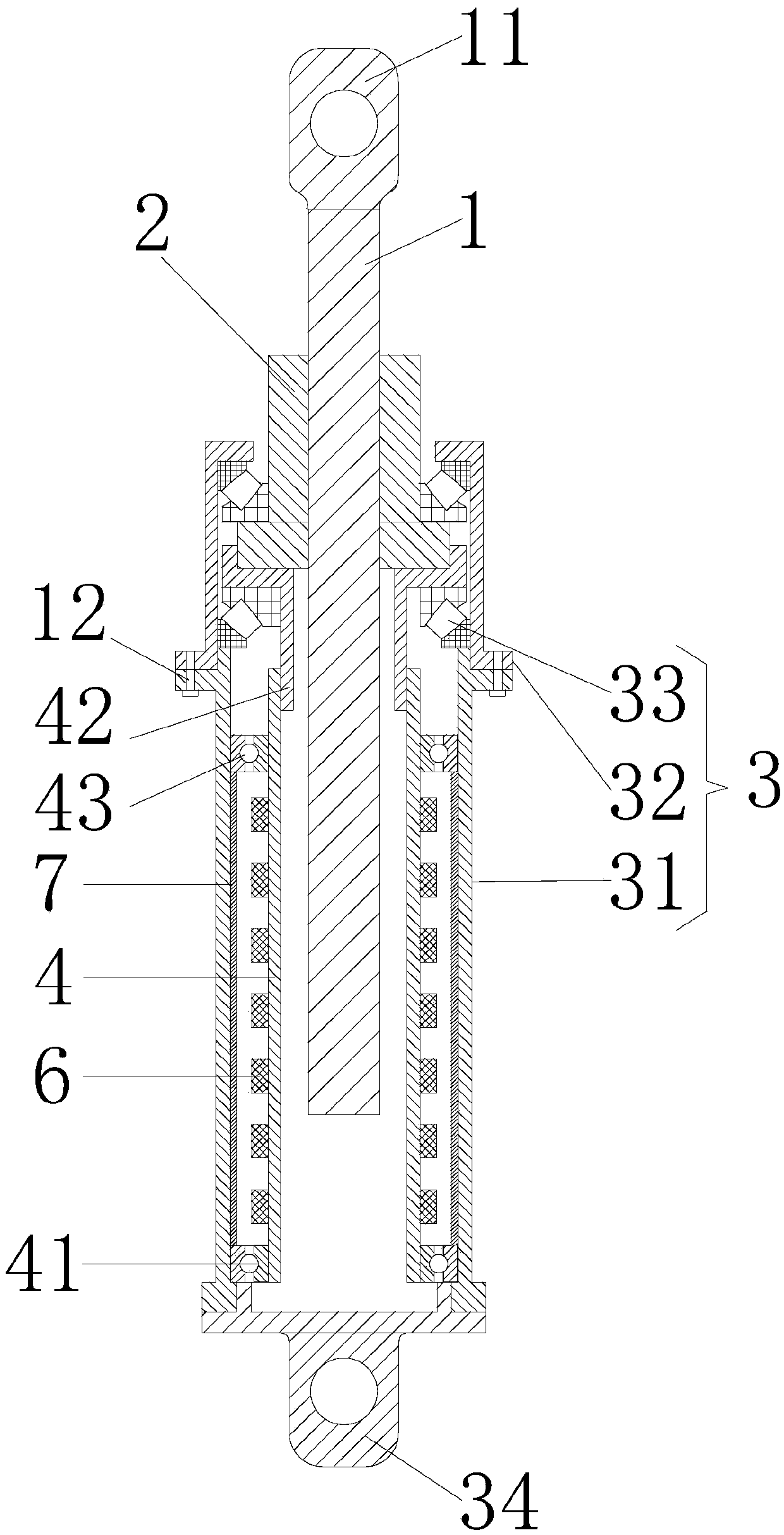

[0036] Such as Figure 1-3 Shown, a kind of electric eddy current axial damper described in the present invention comprises:

[0037] Screw rod 1 and nut 2 adapted thereto;

[0038] A fixed cylinder 3 made of a magnetically conductive material is sleeved on the outside of the screw 1;

[0039] The inner drum 4 made of magnetically permeable material is connected with the nut 2 and sleeved between the screw rod 1 and the fixed drum 3. Several magnets 6 are arranged on the periphery of the inner drum 4, corresponding to the inner drum 4. The inner wall of the fixed cylinder 3 is provided with a conductor pipe 7;

[0040] The outer drum 5 made of magnetically conductive material is connected to the nut 2 and sleeved on the outside of the fixed drum 3. The inner wall of the outer drum 5 is provided with a conductor tube 7, and the corresponding peripheral edge of the fixed drum 3 is provided with Several magnets 6.

[0041] As a preferred solution of this embodiment, the fixed...

Embodiment 2

[0047] Such as Figure 4 As shown, an eddy current axial damper according to the present invention, on the basis of Embodiment 1, the eddy current axial damper also includes a guiding inner tube 8 and a guiding outer tube 9 .

[0048] The guide inner tube 8 is connected to the fixed cylinder 3, the guide outer tube 9 is connected to the screw 1, one end of the guide inner tube 8 is sleeved on one end of the guide outer tube 9, and the guide The outer wall of the inner tube 8 is attached to the inner wall of the guide outer tube 9 and can slide relatively. The inner wall of the guide inner tube 8 is connected with at least one support ring 81 , and all the support rings 81 are connected to the outer wall of the fixed cylinder 3 .

[0049] With this structural setting, the damper needs to be made longer to achieve the maximum damping force and damping coefficient required by the design. When the damper is placed in a horizontal state, the deflection of the middle part of the dam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com