Dust prevention and noise reduction device for concrete reconstruction chiseling and using method thereof

A concrete and dust-proof technology, which is applied in the direction of building construction, earth mover/shovel, mechanically driven excavator/dredger, etc., can solve the problems of no noise reduction treatment, noise pollution, air pollution, etc. Achieve the effect of low material price, strong applicability, energy saving and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

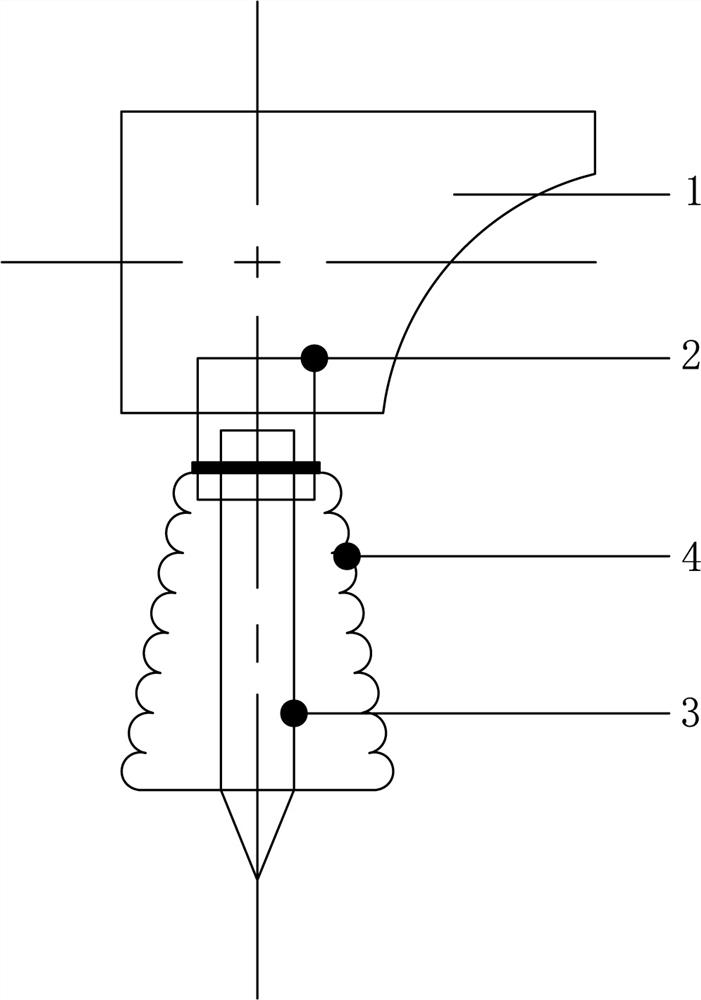

[0021] A dust-proof and noise-reducing device for concrete reconstruction and chisel removal, including a breaking hammer 1, a sleeve 2, a drill rod 3 and a rubber sleeve 4, such as figure 1 As shown, the specific structure is:

[0022] The top end of the sleeve 2 is embedded on the bottom end surface of the breaker 1, the upper part of the drill rod 3 is a cylindrical surface, the bottom of the drill rod 3 is a conical surface, and the top end of the drill rod 3 is movably set in the sleeve 2 and The bottom of the sleeve 2 is blocked, the middle part of the rubber sleeve 4 is provided with a through hole through the top and bottom, the rubber sleeve 4 is hooped on the outer surface of the drill rod 3, and the top of the rubber sleeve 4 is embedded in the inner wall of the sleeve 2 and Between the outer side walls of the drill rod 3, the bottom end of the rubber sleeve 4 is located at the junction of the drill rod 3 cylindrical surface and the conical surface.

[0023] In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com