Resistance spot welding quality detection device and method

A technology of resistance spot welding and detection device, which is used in measuring devices, instruments, and analysis of solids using sonic/ultrasonic/infrasonic waves, etc., can solve problems such as poor detection of virtual welding, inability to detect in-service welded joints, and affecting coupling effects. , to avoid the interference and influence of the ultrasonic detection signal, to eliminate the poor coupling effect, and to achieve the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

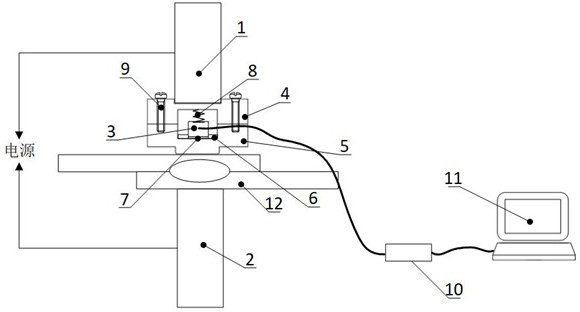

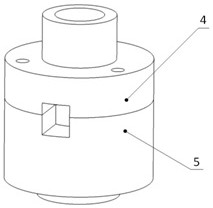

[0075]Examples:

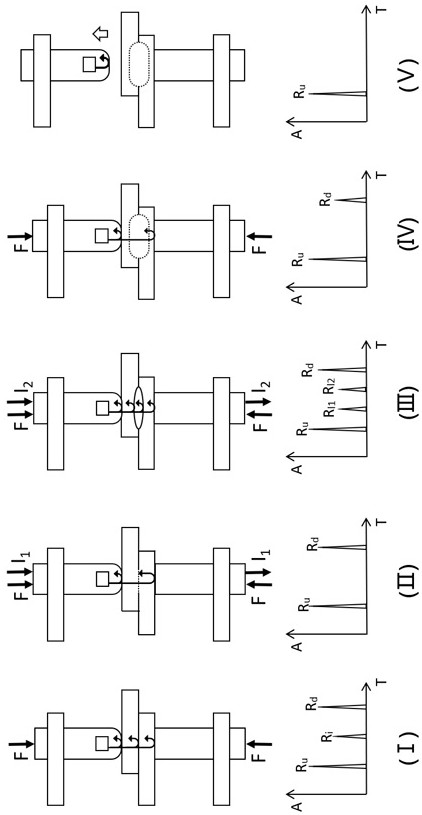

[0076]SeeFigure 7 to Figure 10As shown, this embodiment uses a SUS301L stainless steel plate as the spot welding sample, the plate thickness combination is 2mm+2mm, the ultrasonic probe frequency is 10MHz, and the ultrasonic card sampling frequency is 80MHz.

[0077]According to the characteristics of the obtained M display map, the solder joints are sequentially determined as the inner hole solder joint of the nugget, the virtual solder joint, the splash solder joint, and the solder joint with insufficient nugget size.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com