Industrial robot fault detection method

An industrial robot, fault detection technology, applied in the direction of instrumentation, electrical testing/monitoring, testing/monitoring control system, etc., can solve the problems of unreserved process variables, difficult monitoring, and poor fault detection effect of industrial robots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The following are specific embodiments of the present invention, and further describe the technical solution of the present invention in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

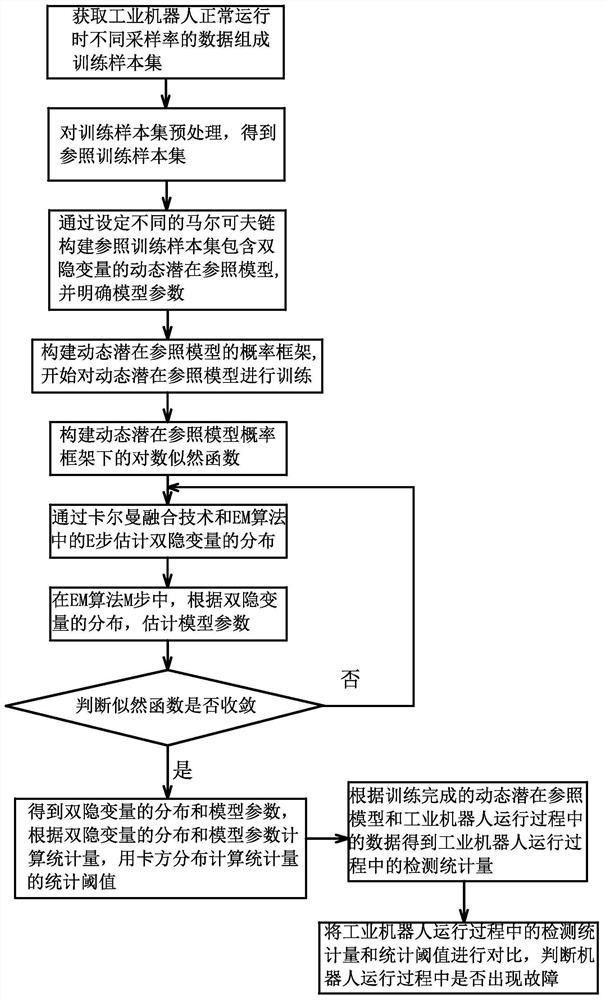

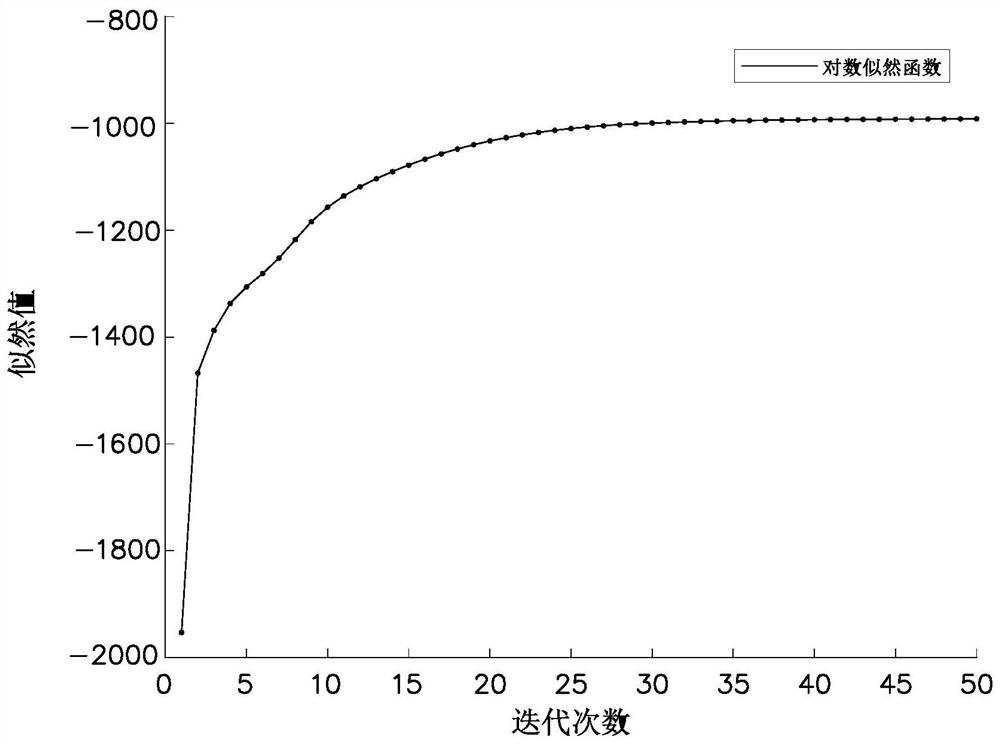

[0074] Such as figure 1 As shown, an industrial robot fault detection method includes:

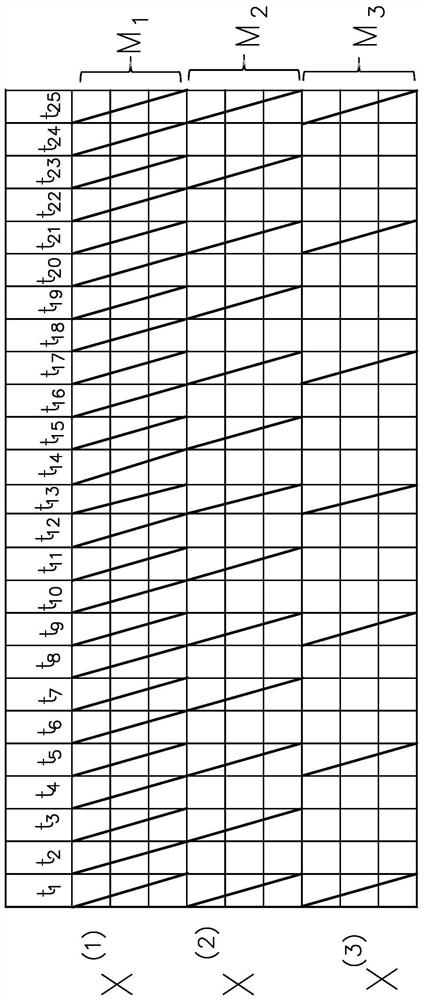

[0075] Step A: Obtain the data of various sampling rates of the industrial robot during normal operation, and form a multi-sampling rate training sample set for building the model. The data collected at different sampling rates include but are not limited to, The actual position value of the joint measured by the angle and position feedback device, the actual joint speed value obtained by the speed sensor, the effective value of the current, the instantaneous acceleration of the end point of the mechanical arm in the horizontal x-axis direction, and the instantaneous acceleration of the end point of the mechanical arm in the horizontal y-axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com