PCB defect detection method based on boundary segment number values

A defect detection and boundary technology, applied in image data processing, instruments, calculations, etc., can solve the problems of long time consumption, poor precision, and no further accurate determination of circuit boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

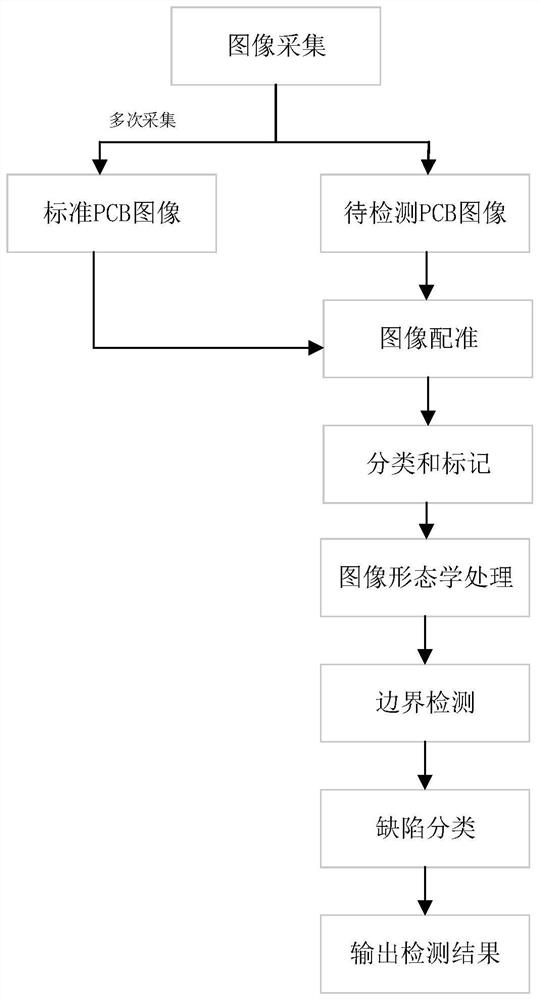

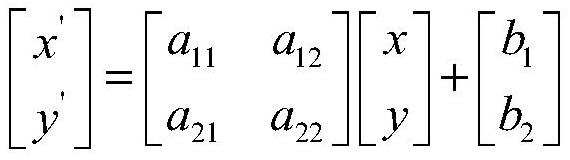

Method used

Image

Examples

Embodiment approach

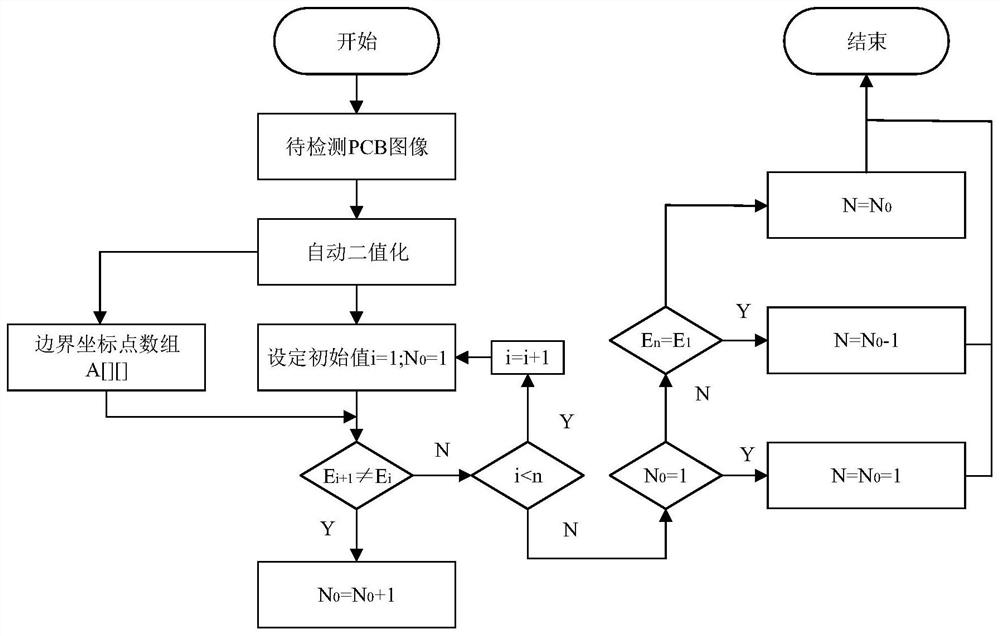

[0072] As a preferred embodiment of the present invention, the step S4 specifically includes:

[0073] S401. Use the method of morphological closed operation to eliminate the noise in the image of the printed circuit board to be tested. Specifically, perform the expansion operation first, specifically: translate the structural element B by a to obtain B a , if B a When X is hit, point a is recorded, and the expansion operation is as follows:

[0074]

[0075] Among them, X is the object to be processed, and B is the structural element;

[0076] Specifically, the processed object refers to the image of the printed circuit board to be tested;

[0077] S402. Carry out the corrosion operation again, and use B to corrode X to obtain a set, which is the set of the origin position of S when B is completely included in X, and the corrosion operation is as follows:

[0078]

[0079] Specifically, the S refers to the pixels in the image of the printed circuit board to be tested...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com