Wire loosening device for communication cable stripping machine

A communication cable and stripping machine technology, which is applied in the direction of cable installation device, cable installation, dismantling/armored cable equipment, etc., can solve the problem that the insulation skin cable core is difficult to peel off, so as to promote separation, promote dislocation separation, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

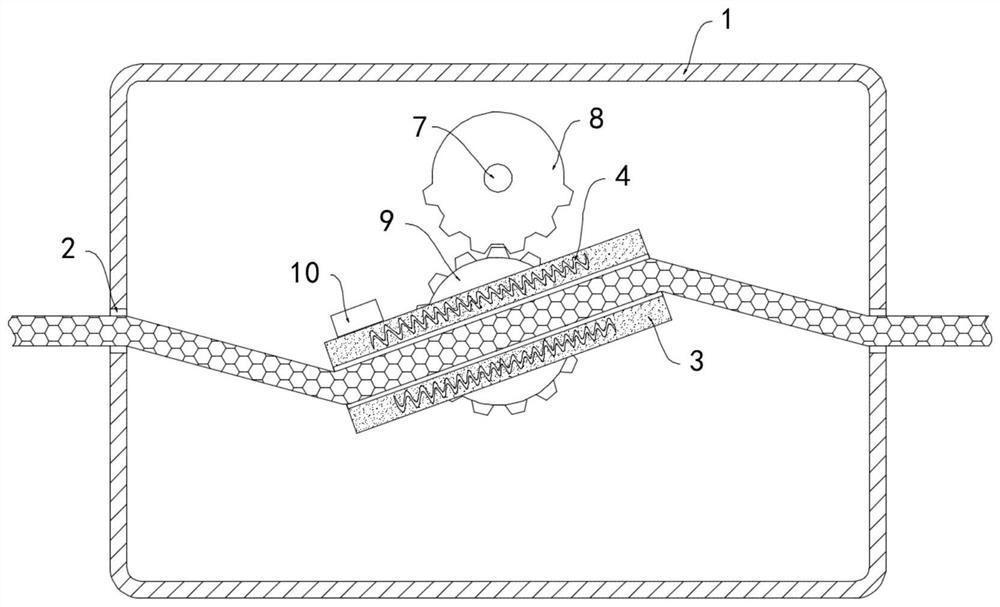

[0021] Such as Figure 1-2 As shown, a wire loosening device for a communication cable stripping machine includes a housing 1, the side walls on both sides of the housing 1 are provided with threading holes 2, the housing 1 is provided with a sleeve 3, and the sleeve 3 is embedded A heating resistance wire 4 is provided, and the heating resistance wire 4 is electrically connected to an external power supply. A temperature alarm 10 is installed on the casing 3. The temperature alarm 10 can monitor the temperature at the casing 3 in real time to prevent the insulation skin from being overheated. melted, and the temperature of the control sleeve 3 is within a suitable temperature range.

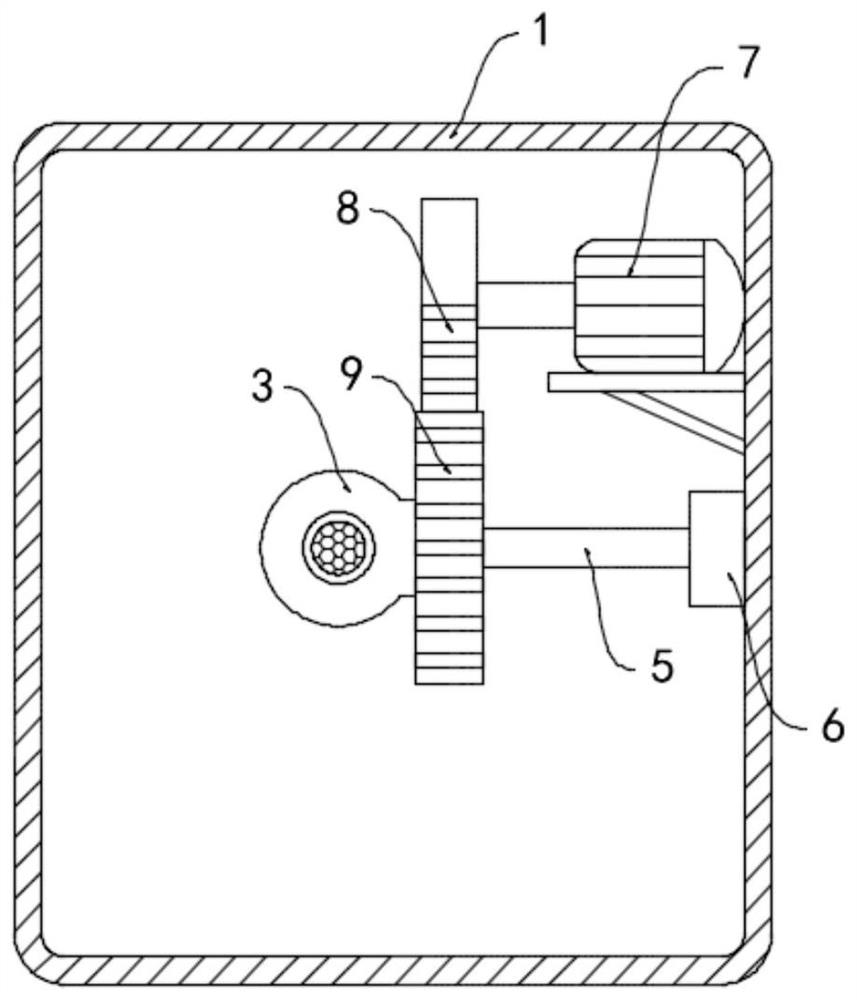

[0022] The casing 3 is rotationally connected with the inner side wall of the housing 1 through the rotating shaft 5, the rotating shaft 5 is provided with a coil spring 6, the inner ring of the coil spring 6 is fixed to the rotating shaft 5, and the outer ring is fixed to the inner side wall of...

Embodiment 2

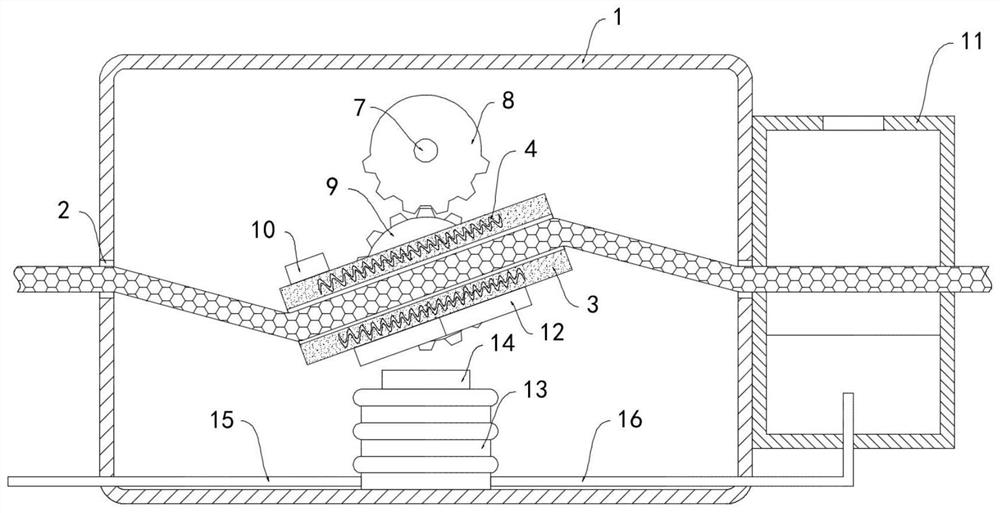

[0026] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that a cooling air box 11 is fixedly connected to the side wall of the housing 1, and a through hole matching the threading hole 2 is provided on the side wall of the cooling air box 11. 3 is fixedly connected to the side wall of the permanent magnet strip 12 extending along its axial direction, the magnetic poles at both ends of the permanent magnet strip 12 are opposite, and the inner bottom surface of the housing 1 is fixedly connected to a vertically arranged airbag 13, and the upper end of the airbag 13 is fixedly connected to There is a magnet block 14 matched with the permanent magnet strip 12, a one-way air intake pipe 15 and a one-way exhaust pipe 16 are fixedly communicated with the side wall of the air bag 13, and the air intake end of the one-way air intake pipe 15 extends to the outside of the housing 1, The air outlet end of the one-way exhaust pipe 16 extends into the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com