Concrete manhole cover pouring mold and pouring method thereof

A technology for pouring molds and concrete, applied in the field of pouring molds for concrete manhole covers, can solve problems such as low work efficiency, easy to bond concrete, and manhole covers are not easy to demould, and achieve the effect of improving work efficiency, smooth surface and saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

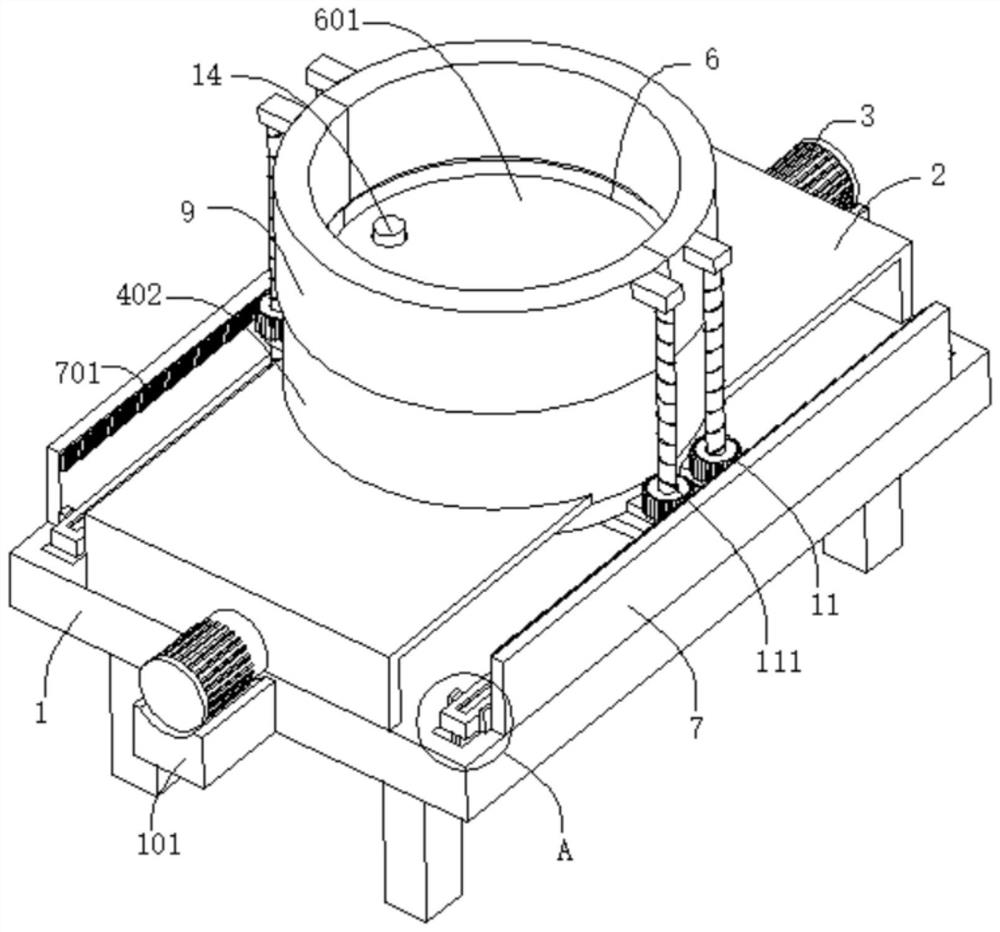

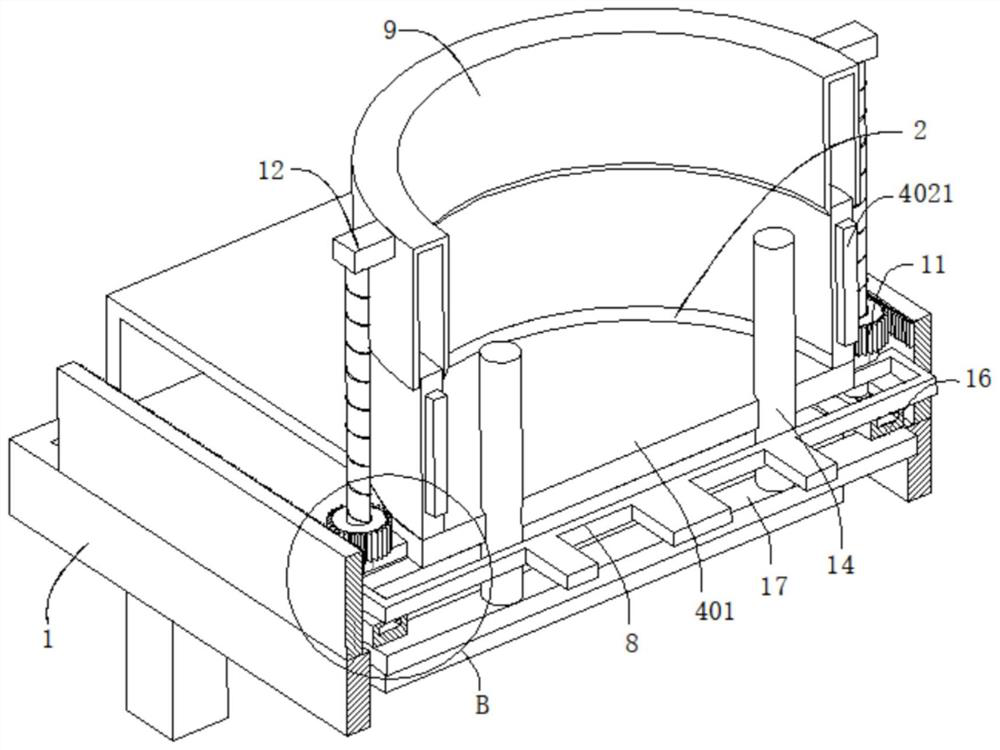

[0038] refer to Figure 1-10, a concrete manhole cover pouring mold, including a workbench 1, the two side walls of the workbench 1 are connected with a support seat 101, the outer wall of the support seat 101 is connected with a motor 3, and the top outer wall of the workbench 1 is connected with two support plates 2 , the outer walls of the two support plates 2 are connected with the first screw rod 201, the output end of the motor 3 passes through the support plate 2 and is fixedly connected with the first screw rod 201, and the outer walls of the two first screw rods 201 are screwed with sleeves 202, the top outer walls of the two sleeves 202 are respectively connected with the first set of molds 4 and the second set of molds 5, the first set of molds 4 and the second set of molds 5 move against each other, and the first set of molds 4 and the second set of molds 5 is provided with a pouring cavity 6, and a pouring part 601 is connected to the pouring cavity 6. The first s...

Embodiment 2

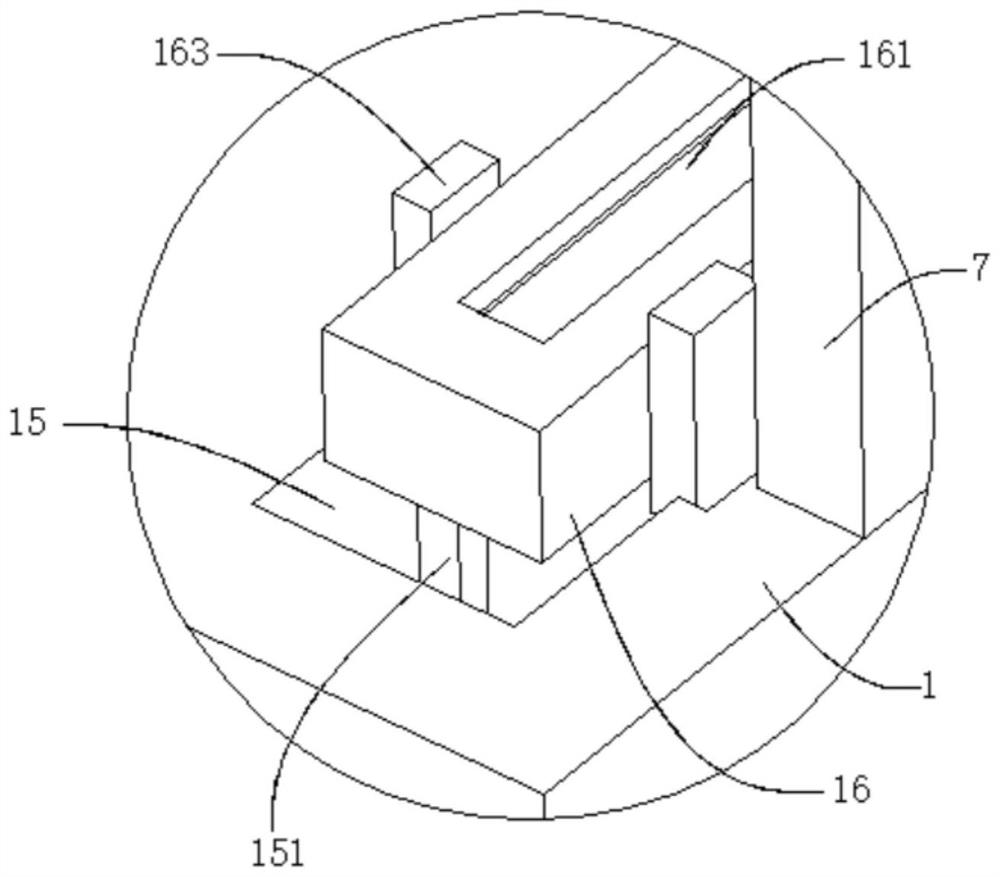

[0045] refer to Figure 1-10 , a concrete manhole cover pouring mold, which is basically the same as that of Embodiment 1, furthermore, the outer wall of the workbench 1 is excavated with a movable groove 15, the movable groove 15 is movably connected with a movable plate 16, and the outer wall of the movable plate 16 is excavated with a chute 161 A slider 162 is slidably connected to the inner wall of the chute 161 , and the slider 162 is fixedly connected to the bottom of the second screw rod 111 .

[0046] The outer wall of the movable plate 16 is connected with a guide bar 163 , and the inner wall of the movable groove 15 is dug with a guide groove 151 matched with the guide bar 163 .

[0047] The outer walls of the first base 401 and the second base 501 are dug with matching through holes 13, and the through holes 13 are movably connected with a movable rod 14, and the bottom of the movable rod 14 is connected with a movable plate 17, and the movable plate 17 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com