Plate-rod type satellite main structure

A satellite main structure, plate-and-rod technology, applied in the direction of artificial satellites, space navigation equipment, space navigation aircraft, etc., can solve the problem of low local strength of the main load-bearing structure, low space utilization rate of the load-bearing tube, not suitable for scattered load and other issues, to achieve the effect of facilitating equipment layout, overcoming weak carrying capacity, and facilitating assembly operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]The present invention will be described in detail below with reference to the drawings and embodiments. Butt ring 1

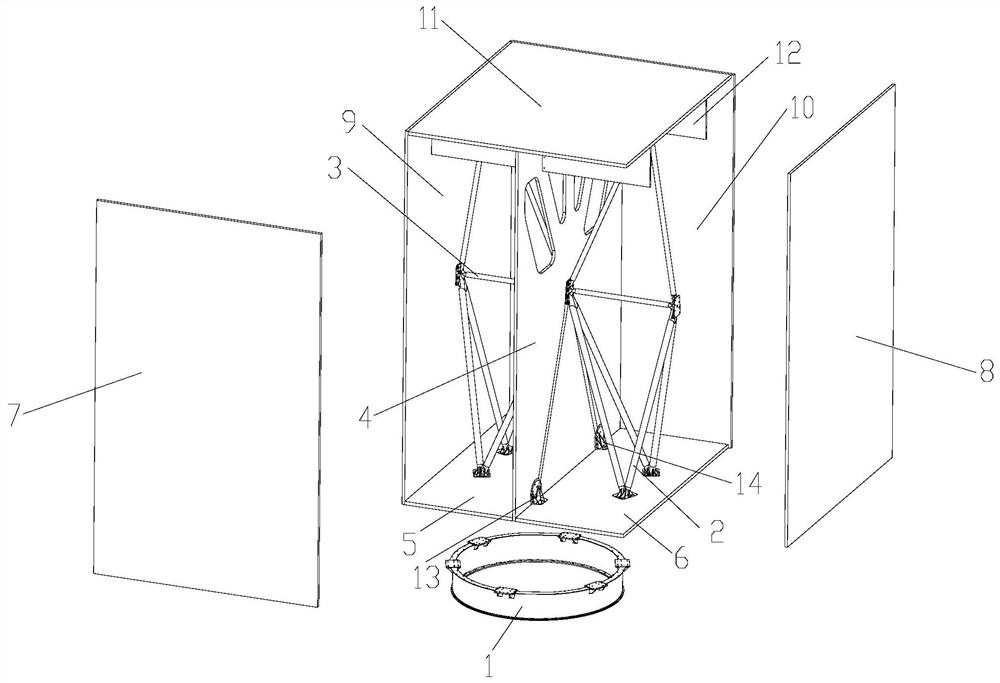

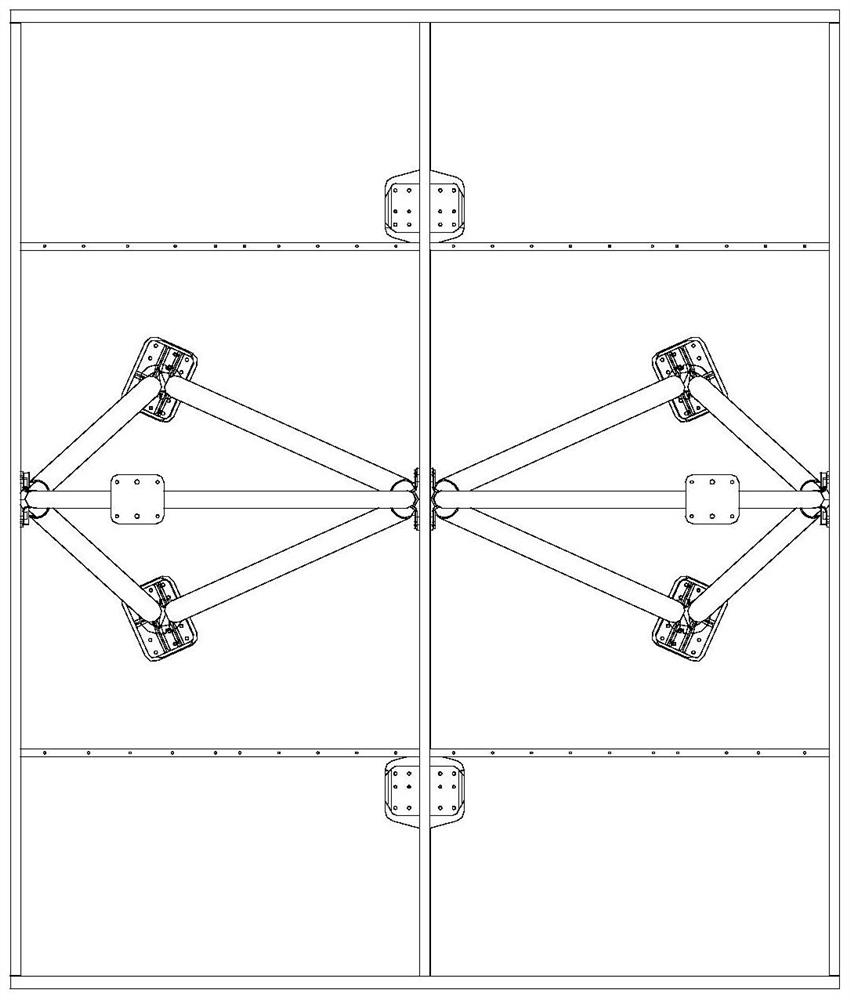

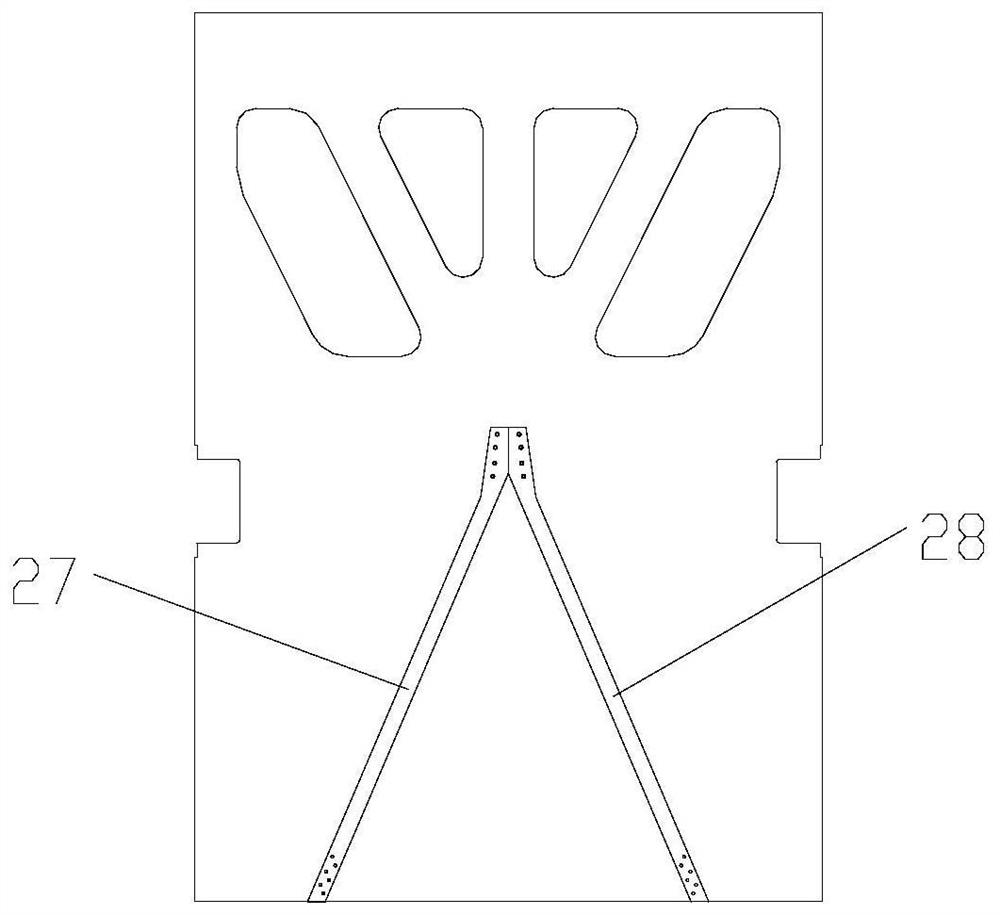

[0041]This embodiment provides a main structure of a slat-to-pole satellite, see AppendixFigure 1-2 , Including: butt ring 1, main bearing partition 4, first rod system 2, second rod system 3, first back floor 5, second back floor 6, counter floor 11 and four structural panels;

[0042]The docking ring 1 is an integral ring-shaped metal frame. The upper end of the docking ring 1 is provided with six main bearing connection flanges evenly distributed along its circumferential direction, and the lower end is a 1194A standard interface for docking with an external carrying interface ;

[0043]The four structural panels are the first structural panel 7, the second structural panel 8, the third structural panel 9 and the fourth structural panel 10; the first structural panel 7, the second structural panel 8, the third structural panel 9 and The fourth structural plates 10 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com