Sealing head of bottle and can sealing machine

A sealing machine and oral technology, applied in the field of sealing equipment, can solve the problems of appearance damage, manual adjustment, and small rotation angle of the belt differential cover, and achieve the effects of good stability, not easy to stop for maintenance, and overcome the tilt of the cover.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

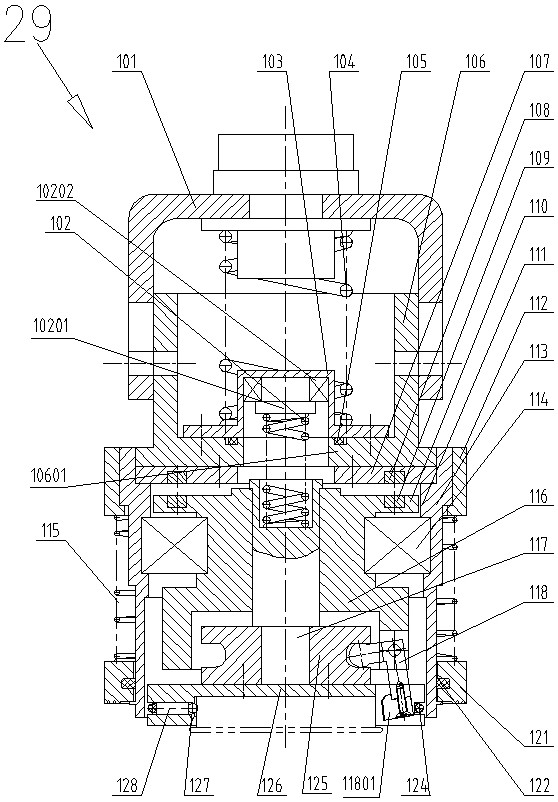

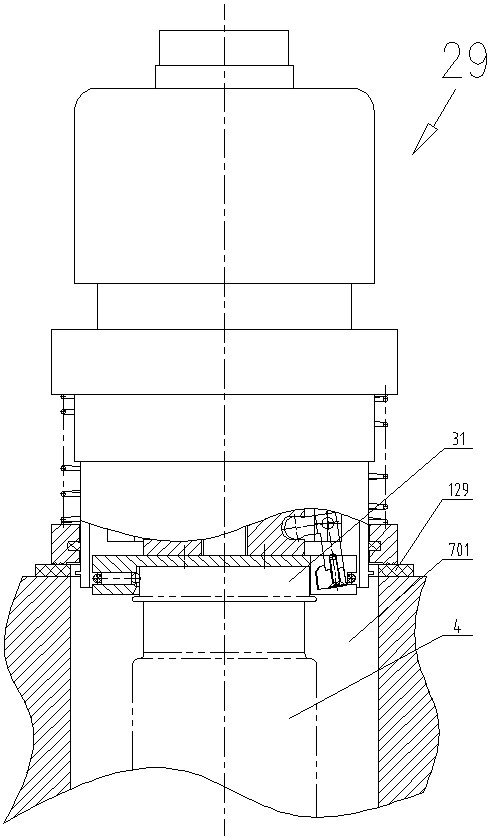

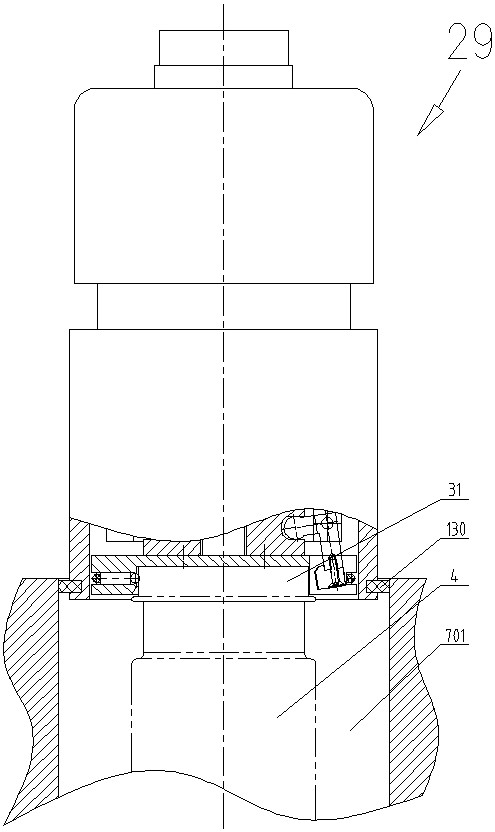

[0019] Such as Figures 1 to 4 As shown, the sealing head of a bottle and can sealing machine of the present invention, the bottle and can sealing machine can be a linear sealing machine, a single head sealing machine or a rotary sealing machine, preferably a rotary vacuum bottle and can sealing machine, the present invention It can be used for vacuum sealing and is suitable for rotary vacuum bottle and jar sealing machines.

[0020] Concrete structure of the present invention is as follows:

[0021] Such as figure 1 As shown, the sealing head 29 includes a sealing head cavity cover whose upper end is connected with a capping driving device, and a cap-taking and screwing mechanism arranged in the sealing head cavity cover is used to drive the screwing of the cap-taking and screwing mechanism. Cap driving mechanism, the cap-taking and screwing mechanism includes a disc-shaped (can also be square, oval, etc. other shapes) cap-removing device 126 arranged at the lower end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com