Prestressed steel strand, steel wire rod for prestressed steel strand and production method of steel wire rod

A technology of prestressed steel strands and production methods, which is applied in the direction of textiles, papermaking, and textile cables, etc., can solve the problems of decreased strength of steel strands and reduced strengthening effect of wire rod deformation, and achieves the prevention of wire breakage and inhibition The effect of forming and improving the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

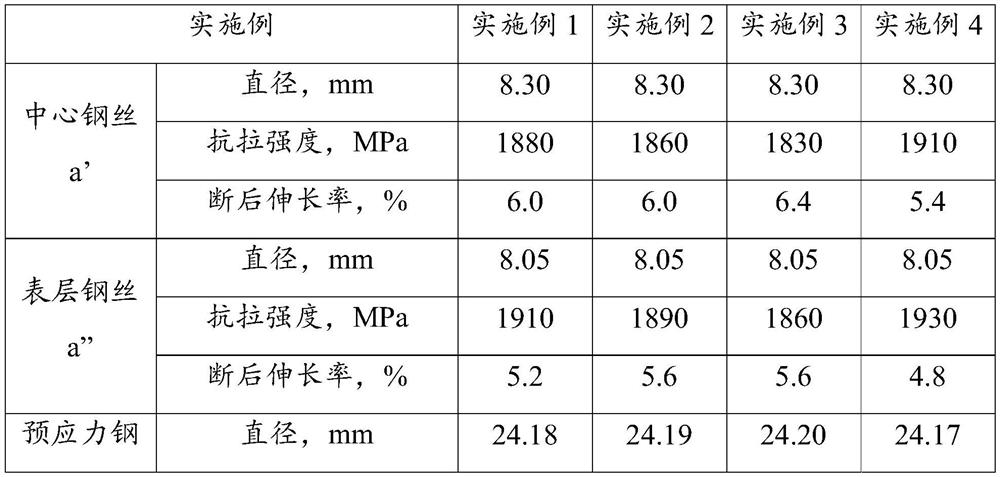

[0030] Specifically, the preparation method of the prestressed steel strand comprises:

[0031] Drawing: drawing the prestressed steel strand with a wire rod into a central steel wire and a surface steel wire;

[0032] Twisting strands: twisting six of the surface steel wires around one of the central steel wires to form a prestressed steel strand of 1×7 structure;

[0033] Stabilization treatment: pre-tensioning the prestressed steel strands and heating them.

[0034]That is to say, the prestressed steel strand can be prepared by further drawing, twisting and stabilizing the wire rod for the prestressed steel strand. For example, the prestressed steel strands with a diameter of 21.5-24.2 mm and a tensile strength ≥ 1860 MPa can be prepared by further drawing, twisting, and stabilizing treatment processes with wire rods, preferably Alternatively, the prestressed steel strand with a diameter of 21.5-22.0 mm and a tensile strength ≥ 1960 MPa can also be prepared.

[0035] An ...

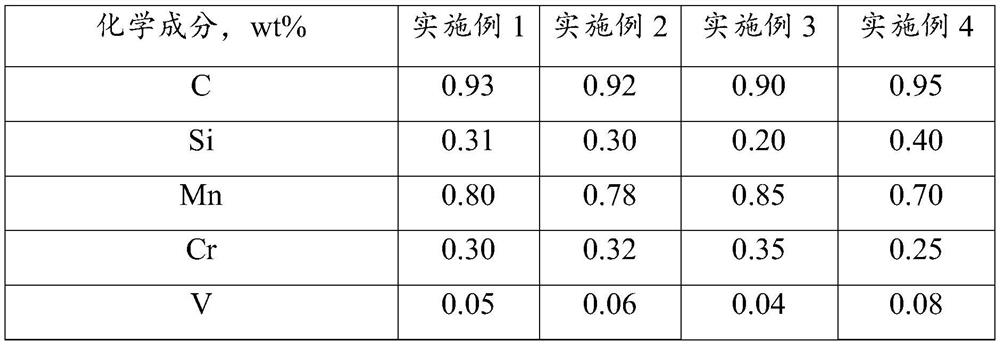

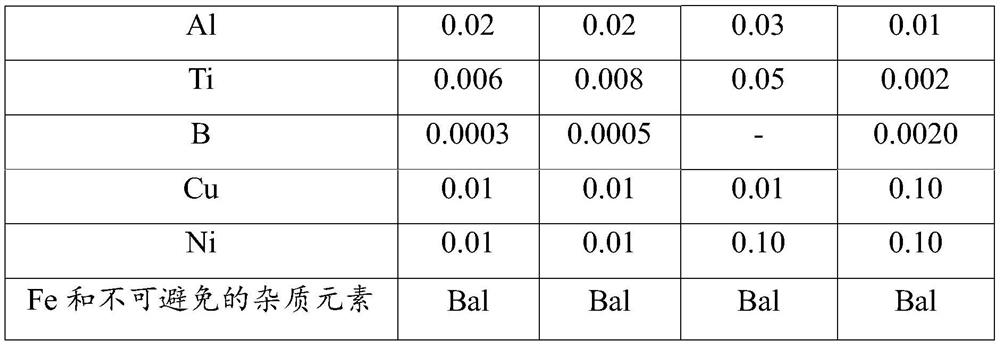

Embodiment 1

[0044] (1) Pre-desulfurization of molten iron;

[0045] (2) Molten steel smelting: using a converter for smelting, the tapping temperature is 1645°C, and the tapping carbon content is 0.10%;

[0046] (3) Refining of molten steel: using processes such as bottom blowing argon, refining outside the furnace and soft blowing to regulate the chemical composition of molten steel and reduce inclusions and gas content;

[0047] (4) Continuous casting: full protection pouring is adopted, the mold adopts electromagnetic stirring, the stirring current is 500A, and the frequency is 4.0Hz. 2.0mm and 2.0mm, thus prepared into 140×140mm 2 The continuous casting slab is cleaned, and the continuous casting slab is cleaned; wherein, the superheat of the tundish is 20°C, the amount of nitrogen added in the continuous casting process is ≤0.0002%, and the casting speed is 2.70m≥min;

[0048] The low-magnification inspection of the cross-section of the continuous casting slab shows that the highes...

Embodiment 2

[0060] (1) Pre-desulfurization of molten iron;

[0061] (2) Molten steel smelting: using a converter for smelting, the tapping temperature is 1642°C, and the tapping carbon content is 0.09%;

[0062] (3) Refining of molten steel: using processes such as bottom blowing argon, refining outside the furnace and soft blowing to regulate the chemical composition of molten steel and reduce inclusions and gas content;

[0063] (4) Continuous casting: full protection pouring is adopted, the mold adopts electromagnetic stirring, the stirring current is 500A, and the frequency is 4.0Hz. 2.0mm and 2.0mm, thus prepared into 140×140mm 2 The continuous casting slab is cleaned, and the continuous casting slab is cleaned; wherein, the superheat of the tundish is 18°C, the amount of nitrogen added in the continuous casting process is ≤0.0002%, and the casting speed is 2.70m≥min;

[0064] The low-magnification inspection of the cross-section of the continuous casting slab shows that the highes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com