Device and method for producing non-woven fabric made of fiber

A technology of non-woven fabrics and equipment, which is applied in the field of non-woven fabrics equipment, can solve the problems of non-uniformity and disadvantage on the surface of non-woven fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

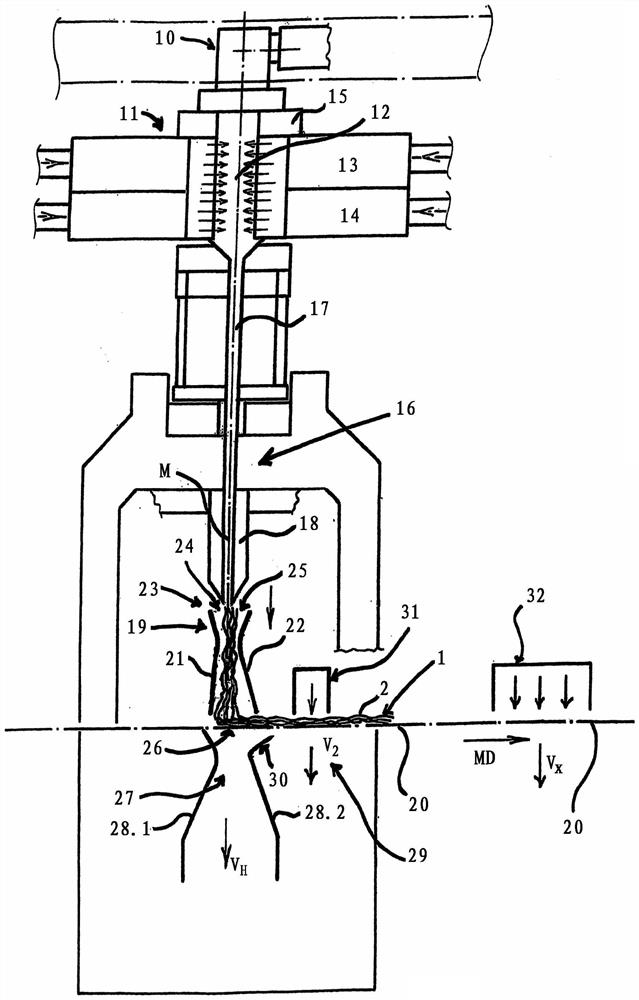

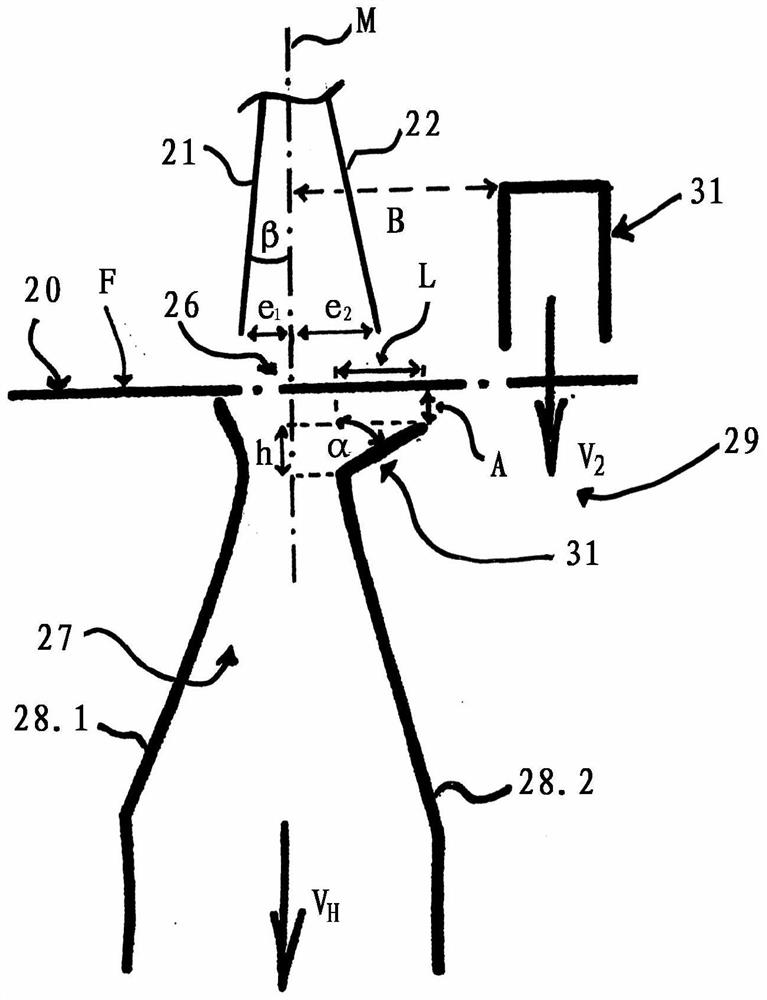

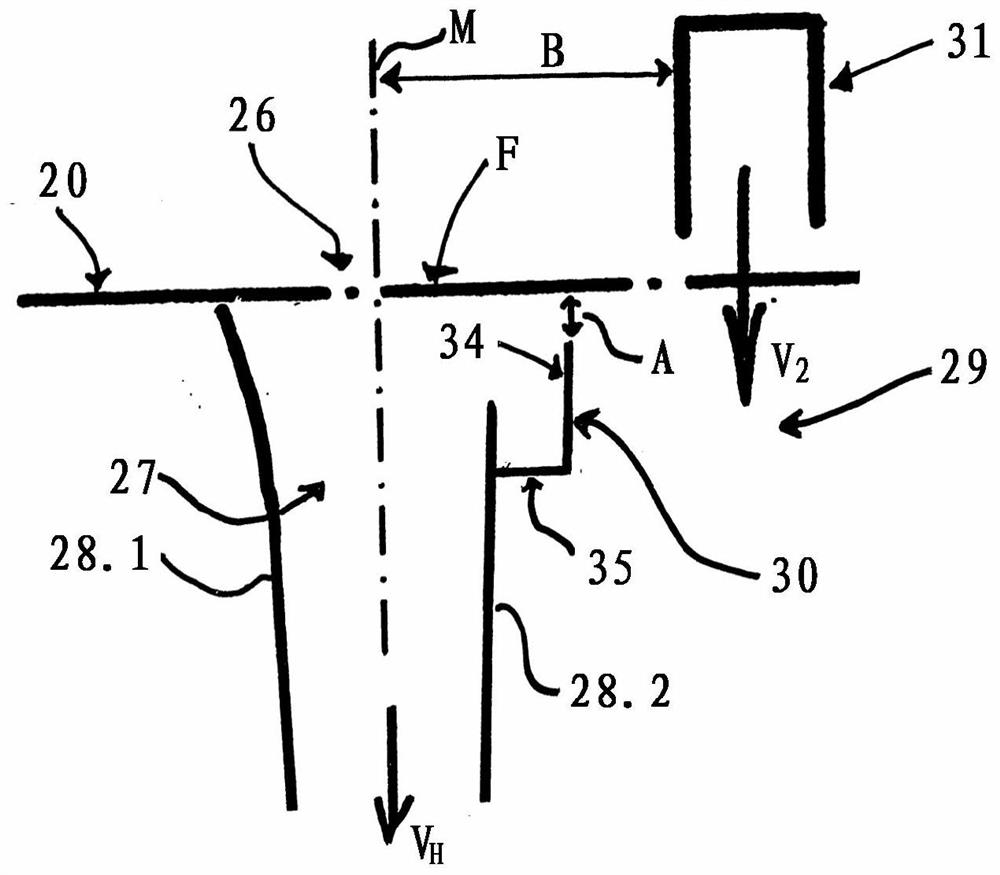

[0049]figure 1 Shows a device according to the invention for the production of non-woven fabrics 1 from thermoplastic fibers, wherein the fibers are preferably continuous filaments 2 in the embodiment, more precisely, according to recommendations and in the embodiment have eccentricity The core-sheath-structure of the two-component filament. The continuous filament 2 with an eccentric core-sheath structure which is particularly preferred within the scope of the present invention will also be explained in detail below. According to the recommendations and in the embodiments, the device of the present invention is configured as a spunbond device for manufacturing spunbond nonwoven fabrics.

[0050]figure 1 A spinning device 10 for spinning continuous filaments 2 is shown. Preferably and in the embodiment, the spun continuous filament 2 is introduced into a cooling device 11 having a cooling cavity 12. Suitably and in the embodiment, two opposite sides of the cooling chamber 12 are provid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com