Propeller with drill rod bending mechanism

A technology of bending mechanism and thruster, which is applied in percussion drilling, reciprocating drilling rigs, drilling equipment and methods, etc., can solve the problems of low work efficiency, difficult to control the bending degree, poor safety performance, etc., and achieve the construction process Convenience, improved construction efficiency and precision, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

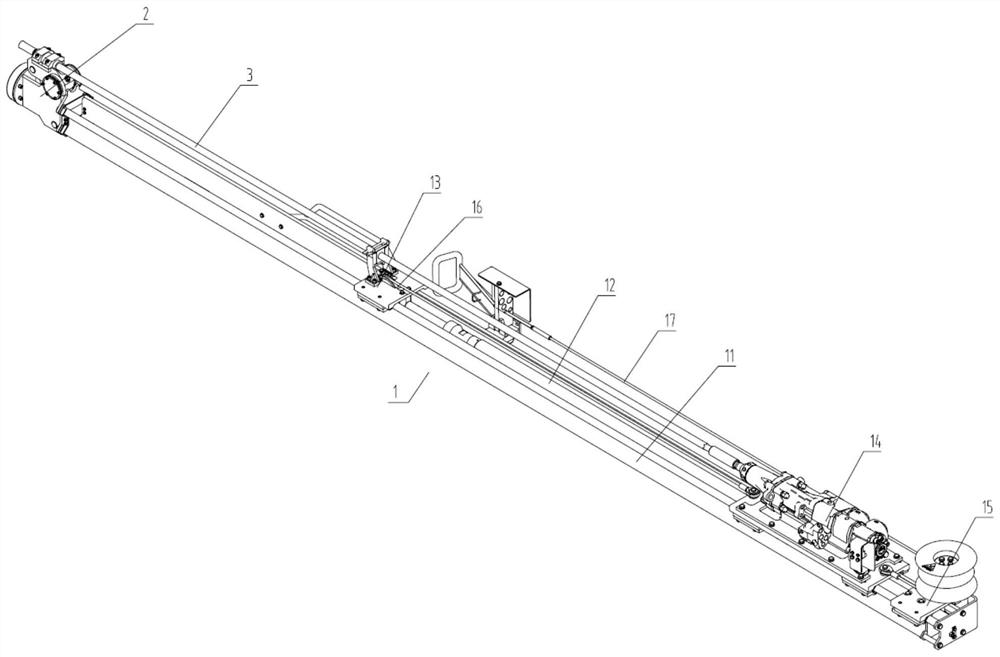

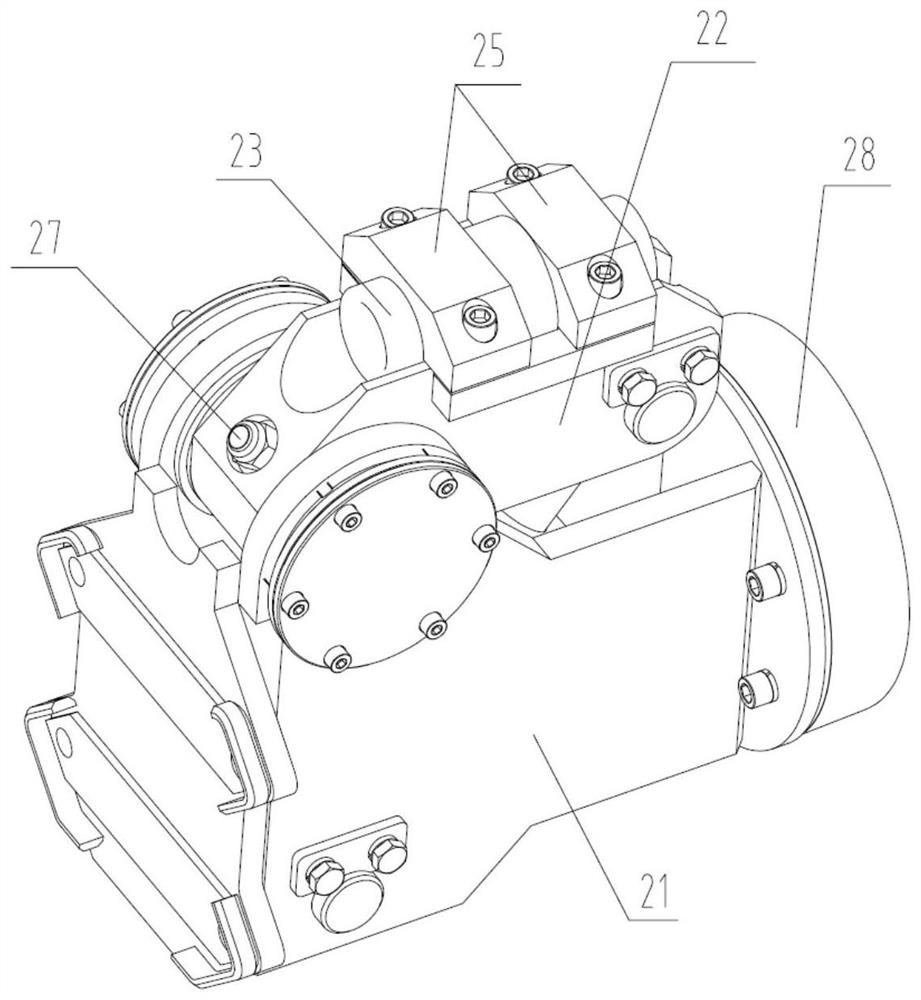

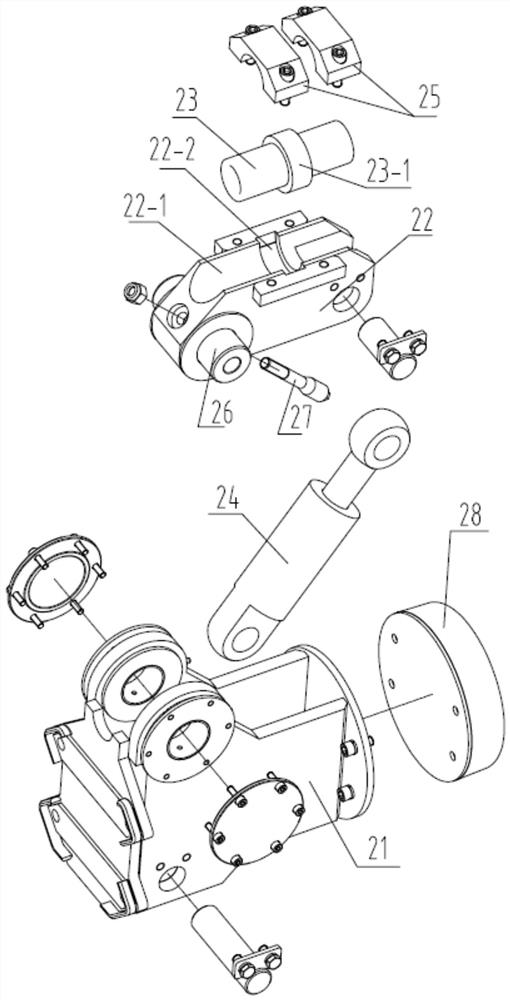

[0023] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 , 5 As shown, the present invention comprises a propeller main body 1, a drill rod bending mechanism 2 is installed on the propeller main body 1, and the drill rod 3 placed on the propeller main body realizes bending of the drill rod head through the drill rod bending mechanism 2, and The drill rod 3 is fixed by threaded connection between the drill rod main body and the drill bit; the drill rod bending mechanism 2 is integral or split, and is located at the push-out end of the propeller main body 1; by setting the drill rod bending mechanism on the propeller, not only the structure It is more compact and the construction process is more convenient, and the construction efficiency and precision are also greatly improved; the drill rod protruding from the advancing beam can be bent to the required angle, and the head of the drill rod can be close to the tunnel wall ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap