Variable displacement oil pump cavitation control method and device

A control method and oil pump technology, applied in pump control, lubrication pump, mechanical equipment, etc., can solve problems such as oil pump damage, engine bearing damage, inability to guarantee oil pump, etc., to reduce maintenance costs and avoid damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

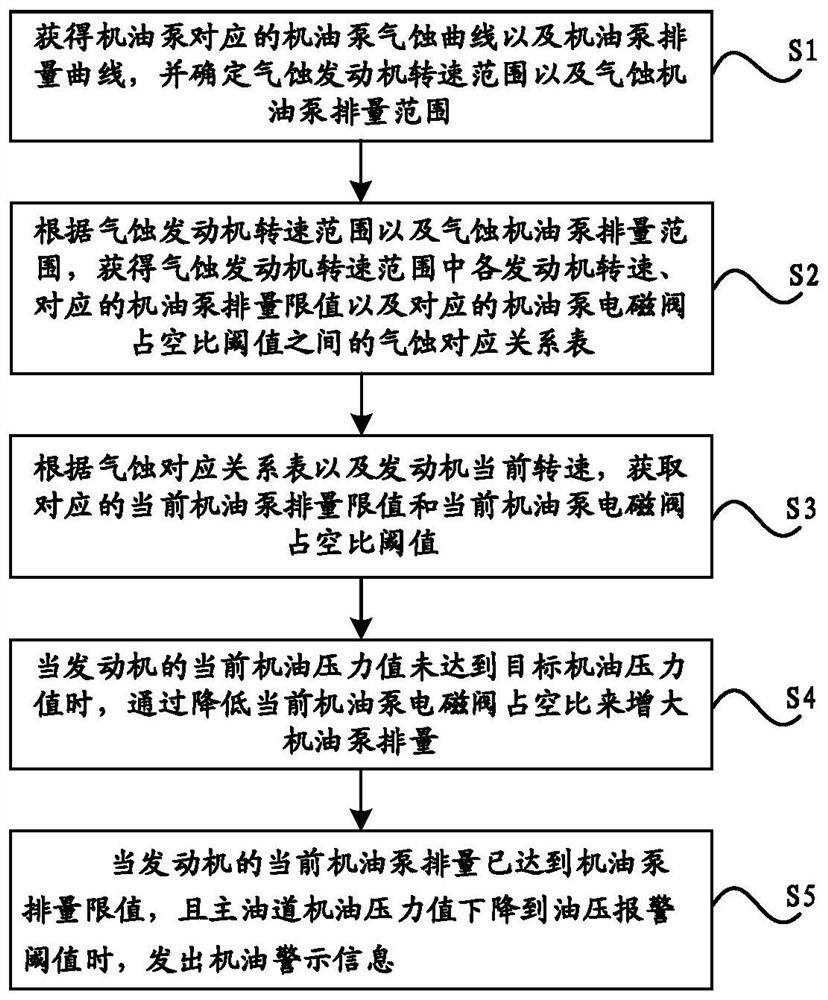

[0063] see Figure 1~3 As shown, the embodiment of the present invention provides a variable displacement oil pump cavitation control method, the method includes the following steps:

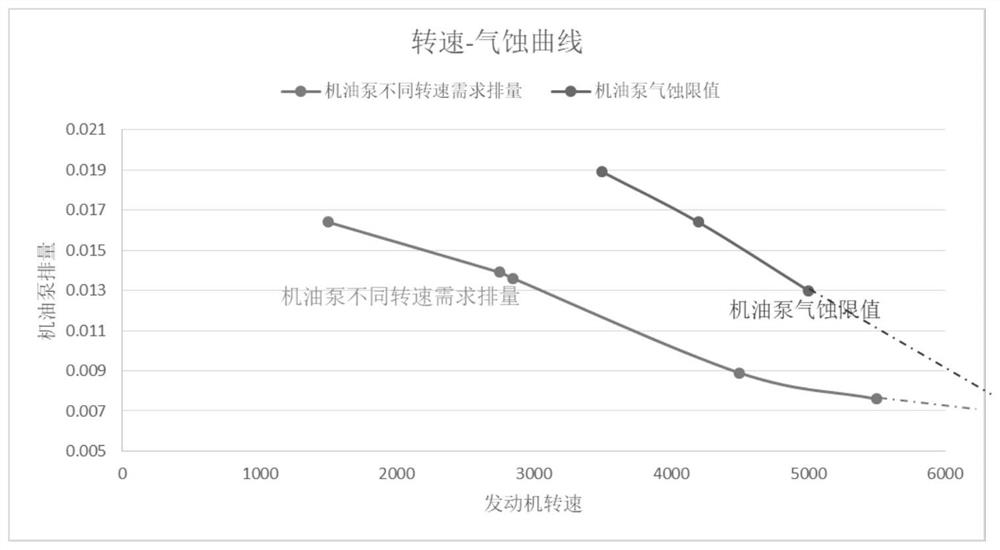

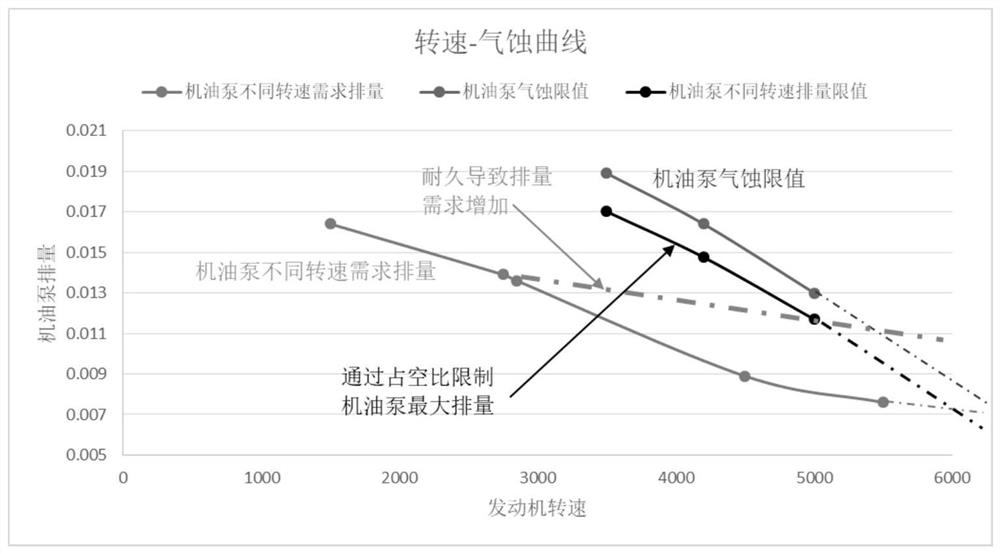

[0064] S1. Obtain the oil pump cavitation curve and the oil pump displacement curve corresponding to the oil pump, and determine the cavitation engine speed range and the cavitation oil pump displacement range;

[0065] S2. According to the cavitation engine speed range and the cavitation engine oil pump displacement range, obtain the engine speed in the cavitation engine speed range, the corresponding oil pump displacement limit, and the corresponding oil pump solenoid valve duty cycle threshold. Correspondence table of cavitation;

[0066] S3. According to the cavitation correspondence table and the current engine speed, obtain the corresponding current oil pump displacement limit and current oil pump solenoid valve duty ratio threshold;

[0067] S4. When the current oil pressure value of th...

Embodiment 2

[0113] see Figure 4 As shown, the embodiment of the present invention provides a variable displacement oil pump cavitation control device, which includes:

[0114] The working parameter acquisition module is used to obtain the oil pump cavitation curve and the oil pump displacement curve corresponding to the oil pump, and determine the cavitation engine speed range and the cavitation oil pump displacement range;

[0115] The cavitation correspondence calculation module is used to obtain the engine speed in the cavitation engine speed range, the corresponding oil pump displacement limit and the corresponding oil pump electromagnetic Cavitation correspondence table between valve duty cycle thresholds;

[0116] A control basis calculation module, which is used to obtain the corresponding current oil pump displacement limit and the current oil pump solenoid valve duty cycle threshold according to the cavitation correspondence table and the current engine speed;

[0117] A cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com