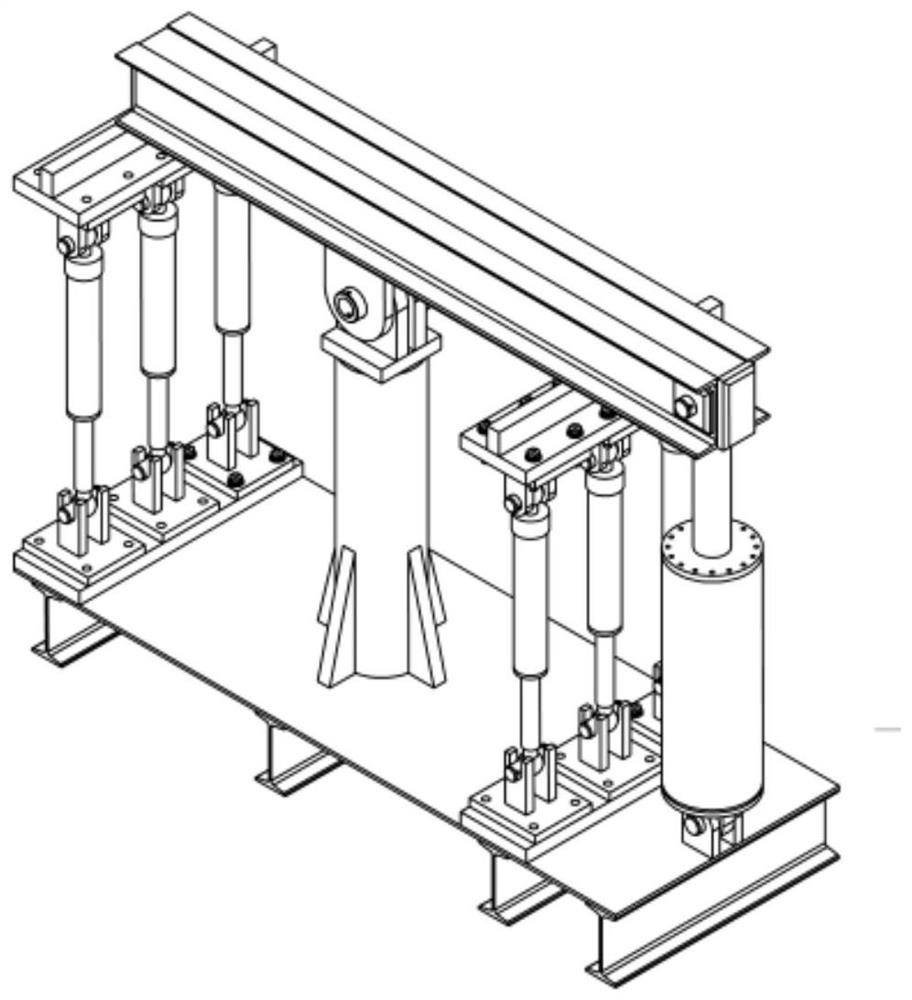

Multi-station hydro-pneumatic spring test board

An oil-gas spring and multi-station technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problems of long test period, safety, and high cost, so as to save test costs and improve safety The effect of guaranteeing and shortening the test test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

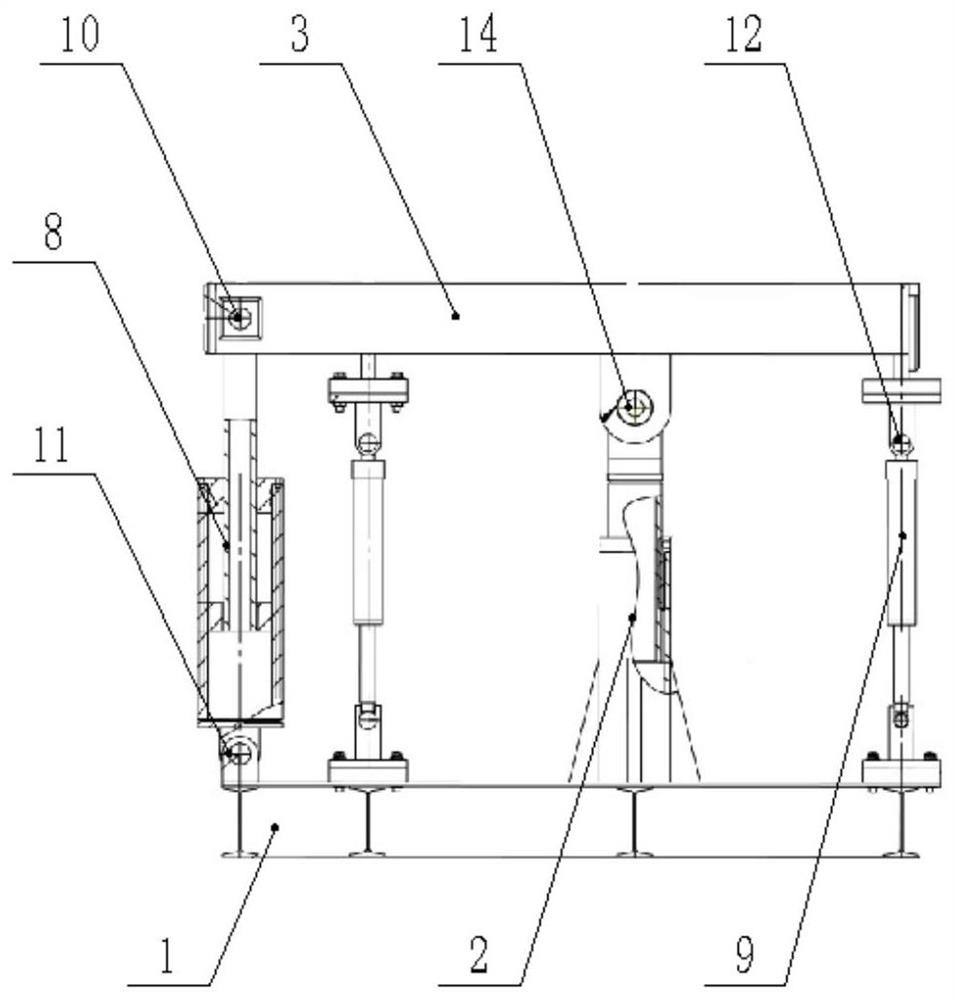

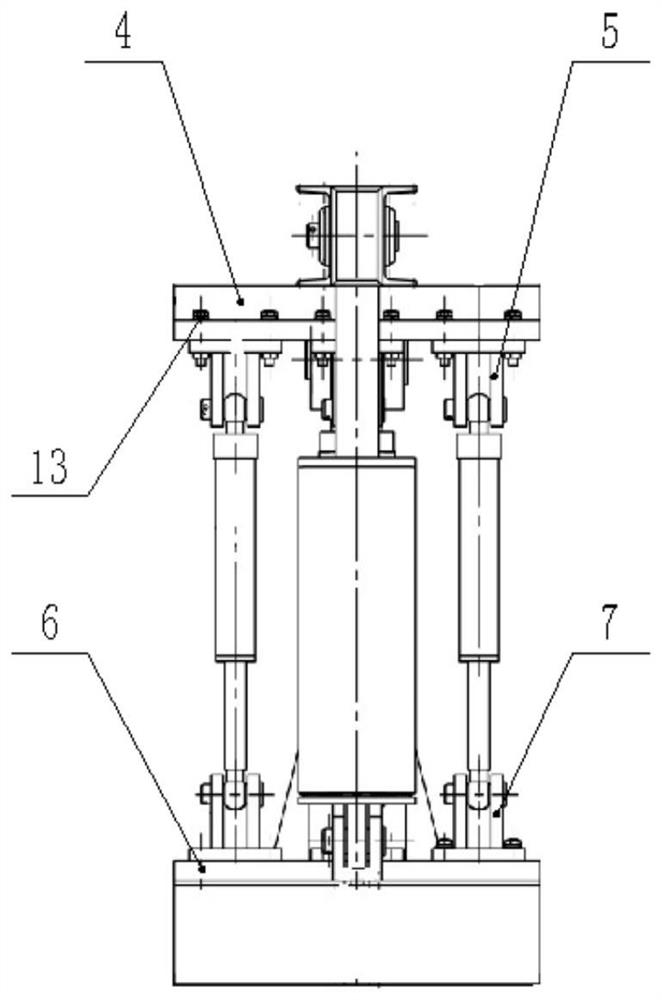

[0021] A multi-station oil-pneumatic spring test bench of this technology will be further described in detail below in conjunction with the accompanying drawings and examples. As shown in the figure, a multi-station oil-pneumatic spring test bench, its operation steps are as follows:

[0022] Step 1, adjust the distance between the stud 19 and the screw sleeve 18 in the column 2 between the platform 1 and the beam 3, so that the distance between the upper flange 5 and the lower flange 7 on the left and right sides is equal, and equal to the oil and gas Lock the nut 20 at the middle position of the stroke of the spring 9; Step 2, use the cylinder connecting pin 14 to symmetrically hang the oil-pneumatic spring 9 between the upper flange 5 and the lower flange 7 on both sides of the column 2; Step 3, inside the oil-pneumatic spring 9 At the same time, the low-pressure gas is charged, and the extension and retraction of the piston rod of the active cylinder 8 pushes the crossbeam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com