Multi-round thermal cycle test device for thermal production well casing pipe, and using method thereof

A test device and technology for thermal recovery wells, applied in the direction of measuring devices, testing material strength by applying repetitive force/pulsation force, instruments, etc., can solve problems such as casing damage in thermal recovery wells, and achieve the effect of reducing axial strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

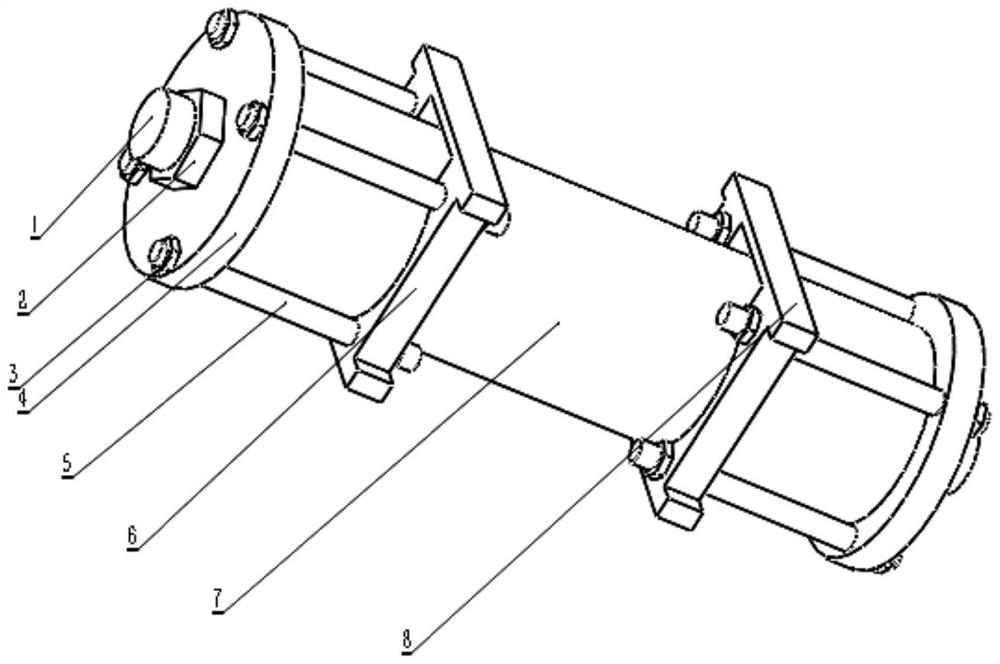

[0035] see figure 1 and figure 2 , The size requirements of the test casing: φ180mm, wall thickness 9.17mm. Install the casing on the large bolts and fix both ends with flanges. Turn on the temperature monitor, set the test temperature to 350°C, and hold the temperature for 24 hours. The temperature monitor gradually rises at a rate of 10°C / min, and reaches the set temperature after 35 minutes. When the temperature detector reaches the set temperature value, turn on the non-contact strain gauge to monitor the strain change of the casing material in real time under the working condition of 350°C. The temperature, strain, and time data of the casing material during the test will be transmitted to the data collection and analysis system. When the holding time is reached, choose air cooling to gradually lower the temperature. This process is a heat recovery well casing thermal cycle test.

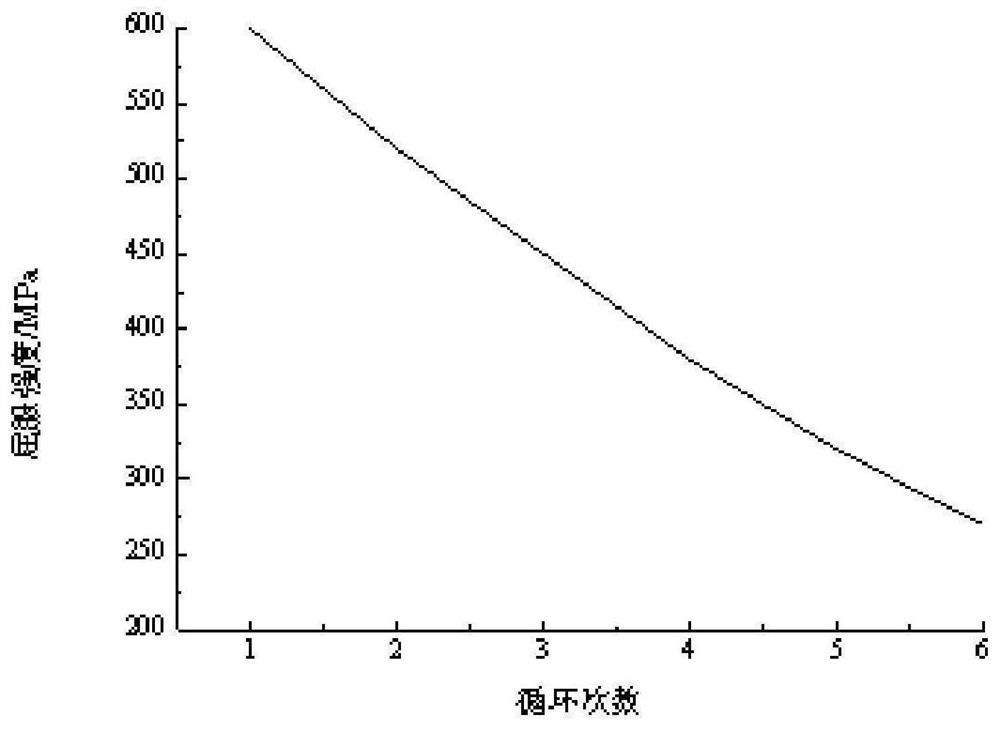

[0036] After 0, 3, and 6 times of thermal cycle tests on casings in thermal recovery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com