Phase identification method by utilizing electron diffraction

An electron diffraction and diffraction ring technology, which is used in material analysis, measurement devices, and instruments using wave/particle radiation, and can solve problems such as small grain size, strong preferred orientation, and difficult phase identification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

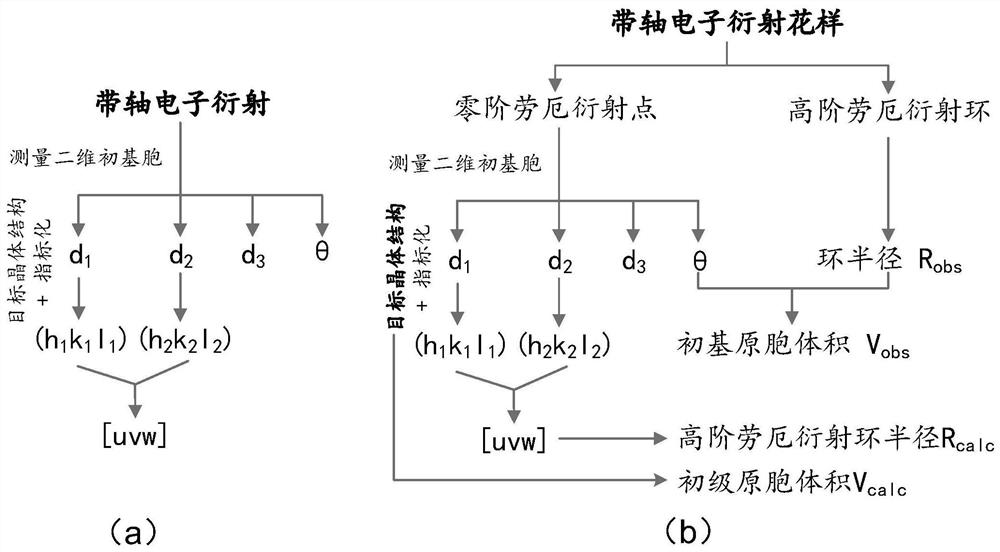

Method used

Image

Examples

Embodiment 1 2

[0066] The phase identification of embodiment 1 titanium dioxide

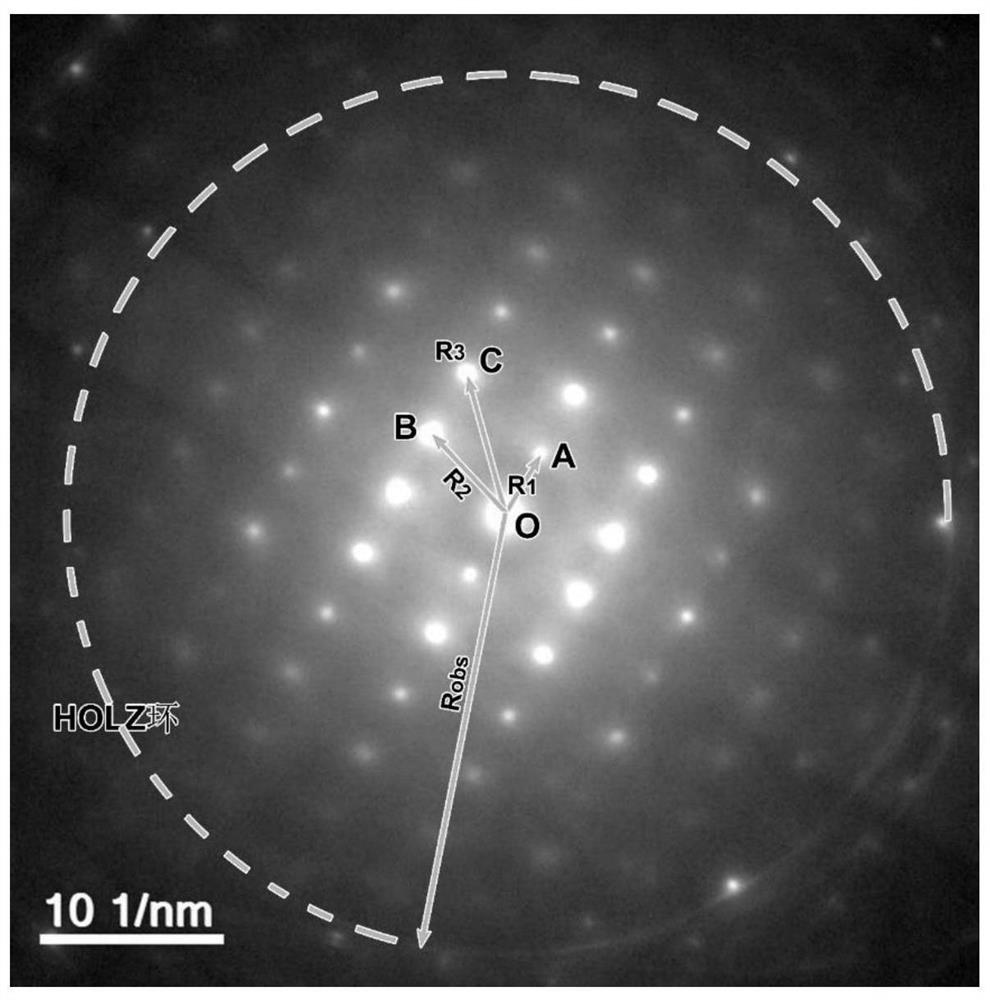

[0067] 1) Record an axial electron diffraction pattern containing high-order Laue diffraction rings of titanium dioxide (titanium dioxide gel sintered at 500°C for 6 hours), as shown in figure 2 . The electron diffraction pattern was recorded with a JEOL JEM-2100 transmission electron microscope at 200 kV, camera length L = 100 mm.

[0068] 2) Measure the zero-order Laue diffraction point and the radius of the high-order Laue diffraction ring of titanium dioxide;

[0069] Take the transmission spot as the origin O of the two-dimensional primordial cell, and take the nearest neighbor diffraction points A and B as the adjacent edges to construct a two-dimensional primordial cell, as figure 2 shown. Measure OA, OB, OC (OC is the diagonal) and ∠AOB (where ∠AOB=72.2°) and R obs , thus getting R 1 , R 2 , R 3 and θ. According to the formula Rd=Lλ, where For the wavelength of the 200kV electron beam, calcu...

Embodiment 2

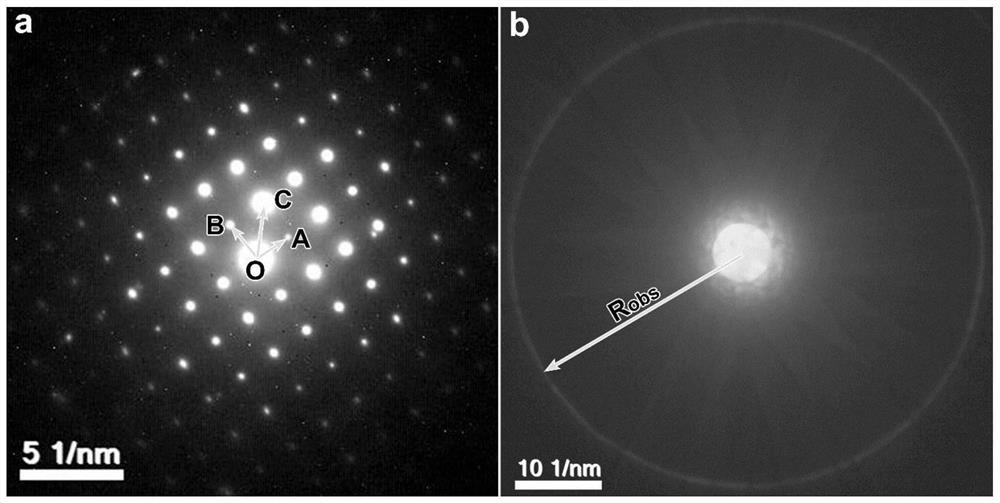

[0096] Example 2 Phase recognition of titanium dioxide prepared by hydrothermal method

[0097] 1) Titanium dioxide nanocrystals prepared by hydrothermal method have small crystal grains and poor crystallinity, so it is difficult to record zero-order Laue diffraction points and high-order Laue diffraction rings on the same electron diffraction pattern. To this end, we use a JEOL JEM-2100 transmission electron microscope to record the zero-order Laue diffraction points of the crystal grains by nanobeam electron diffraction at 200kV, and the high-order Laue diffraction rings by converging beam electron diffraction. The camera length L=100mm, such as image 3 shown in a-b.

[0098] 2) Measure the radius of the zero-order Laue diffraction point and the high-order Laue diffraction ring;

[0099] Take the transmission spot as the origin O of the two-dimensional primordial cell, and take the nearest neighbor diffraction points A and B as the adjacent edges to construct a two-dimens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap