Apparatus and method for distributing interstitial material in battery

A technology of interstitial material and equipment, applied in the direction of secondary batteries, battery pack parts, battery boxes/jackets, etc., can solve the problems of the deformability and adaptability of cooling elements or thermally conductive elements, but not flexibility and flexibility. , to achieve the effect of reducing mechanical stress and shortening process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

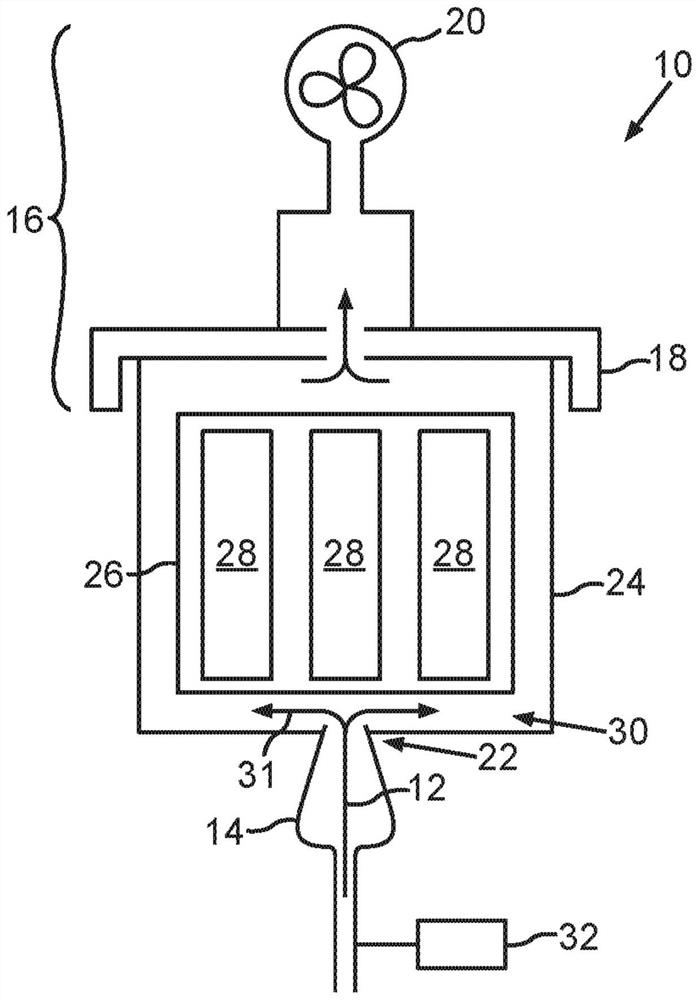

[0035] figure 1 A distribution device 10 for distributing caulk 12 is shown. In the embodiment shown here, the distribution device 10 has an injection nozzle 14 and a vacuum generating device 16 . Furthermore, the vacuum generating device 16 shown here has a cover 18 and a pump 20 arranged on the cover.

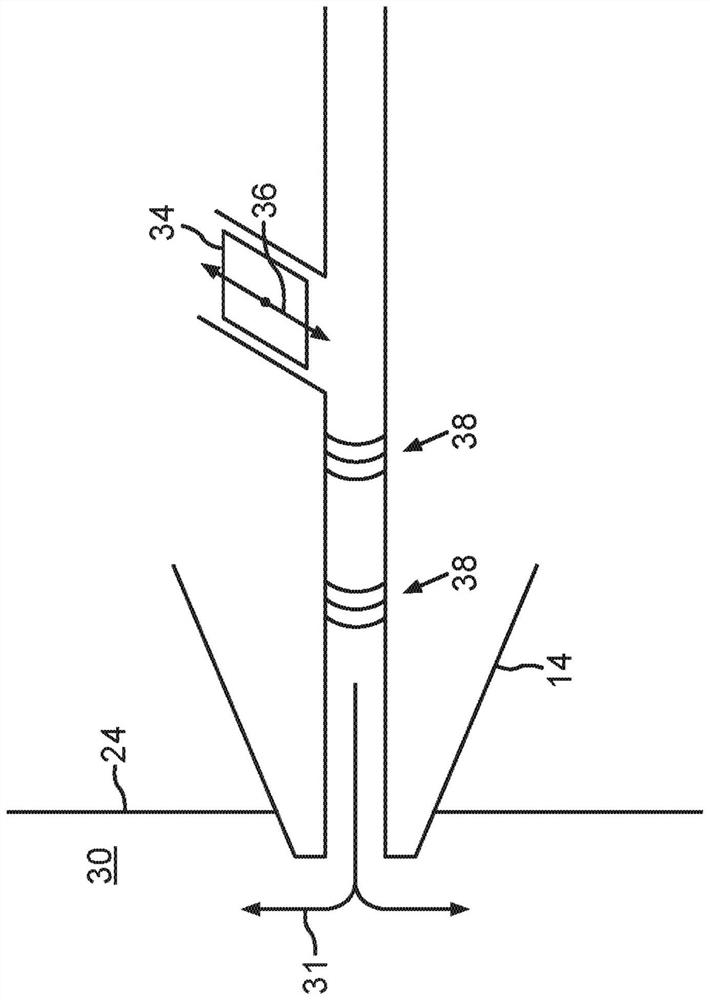

[0036] exist figure 1 In the illustrated embodiment, the injection nozzle 14 is connected to the battery housing 24 at a predetermined injection site 22 . A battery module 26 including a plurality of battery cells 28 is arranged inside the battery housing 24 . exist figure 1 In , a cavity 30 is shown between the battery housing 24 and the battery module 26 . With the aid of arrow 31 at figure 1 It is explained how the caulk 12 is sucked into the cavity 30 between the battery housing 24 and the battery module 26 by the negative pressure generated by the negative pressure generating device 16 and distributed in the cavity. exist figure 1 In the exemplary embodiment show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com