10kV-oriented semi-automatic switch trolley push-pull device

A technology of switch trolley and push-pull device, which is applied in the direction of switchgear, switchgear parts, substation/switch layout details, etc., which can solve the problems of low automation and achieve the effect of simplifying push-pull and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

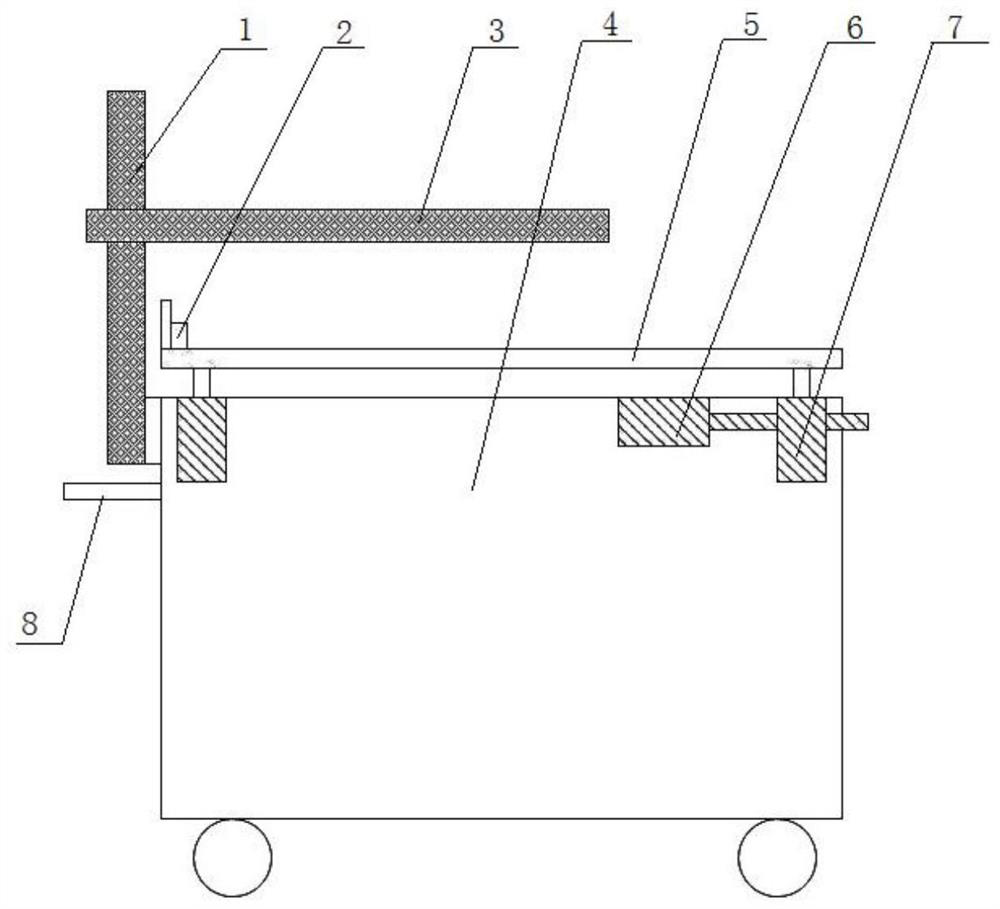

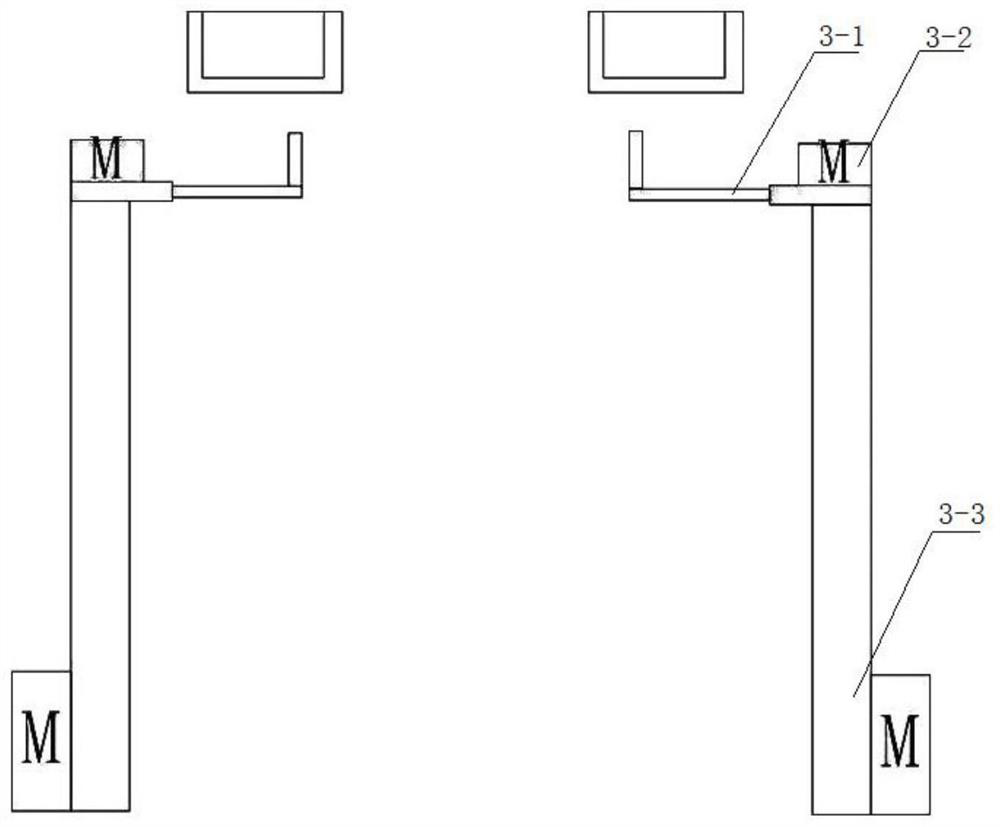

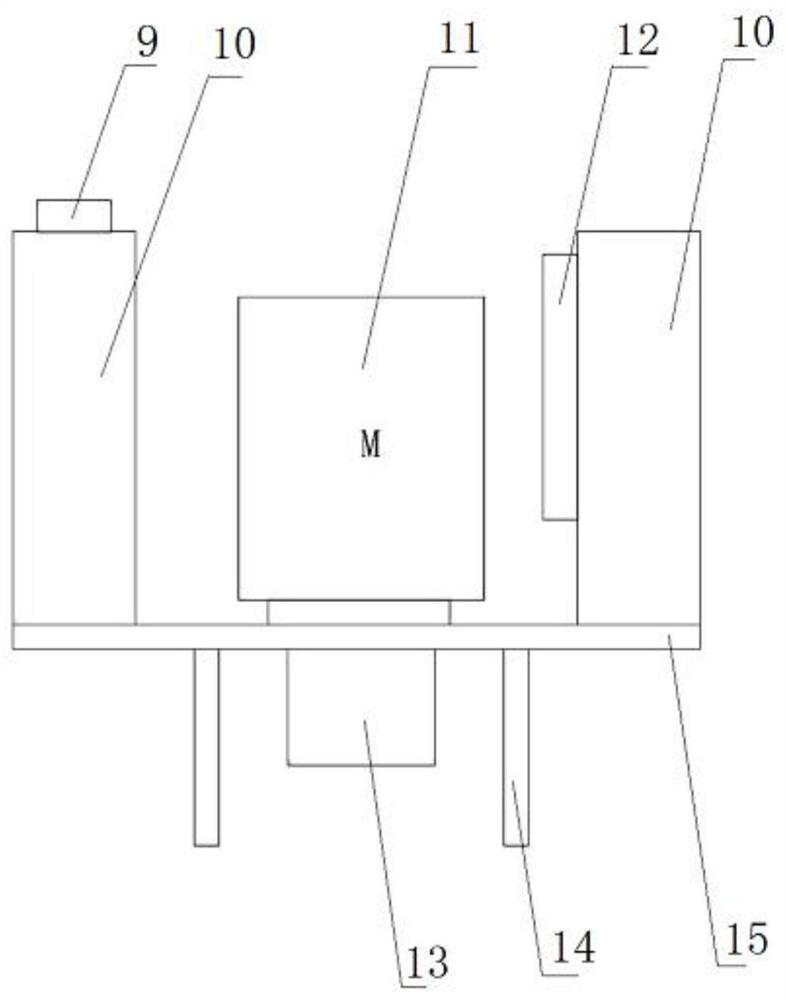

[0019] A 10kV-oriented semi-automatic switch trolley push-pull device, including a transfer vehicle 4, a platform 5, a mechanical arm 3 and an electric crank. Two handles 8 are symmetrically fixed on the side plate of the transfer vehicle, and two mechanical arm lifting mechanisms 1 are symmetrically fixed above the handle, and the two mechanical arm lifting mechanisms are respectively connected to two mechanical arms. Four platform elevating mechanisms 7 are fixed symmetrically at the four corners of the top of the transfer vehicle, and the four platform elevating mechanisms are fixed with the bottom surface of the platform to drive the platform to move up and down. A limit switch 2 is installed on one side of the platform close to the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com