Edible fungus cultivation material fermentation equipment and fermentation method

A technology of fermentation equipment and fermentation method, which is applied in the direction of botany equipment and method, organic fertilizer equipment, cultivation, etc., can solve the problems of easy agglomeration, long cycle, large floor area, etc., and avoid unevenness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

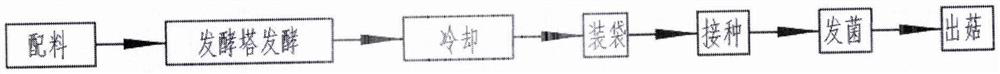

Method used

Image

Examples

Embodiment approach

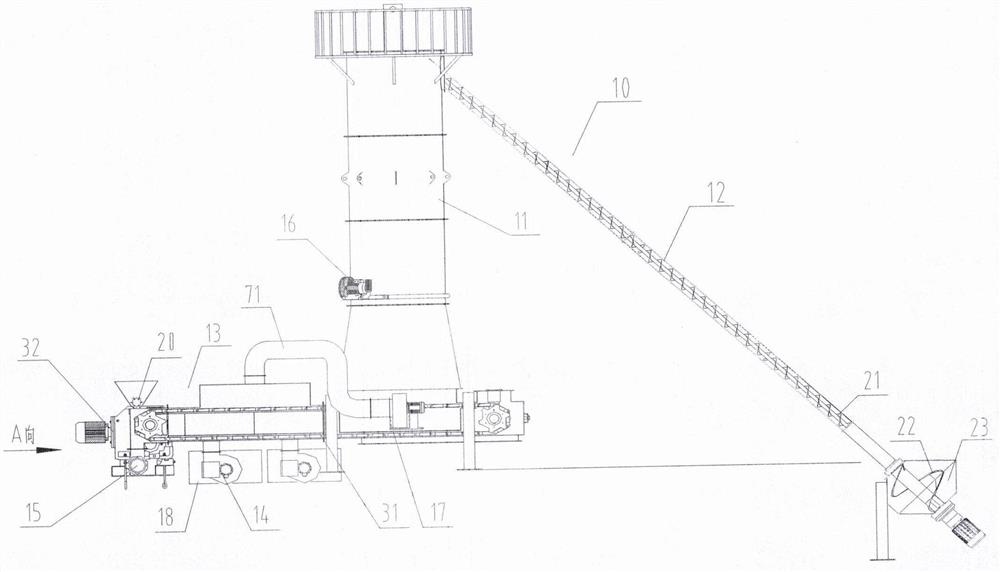

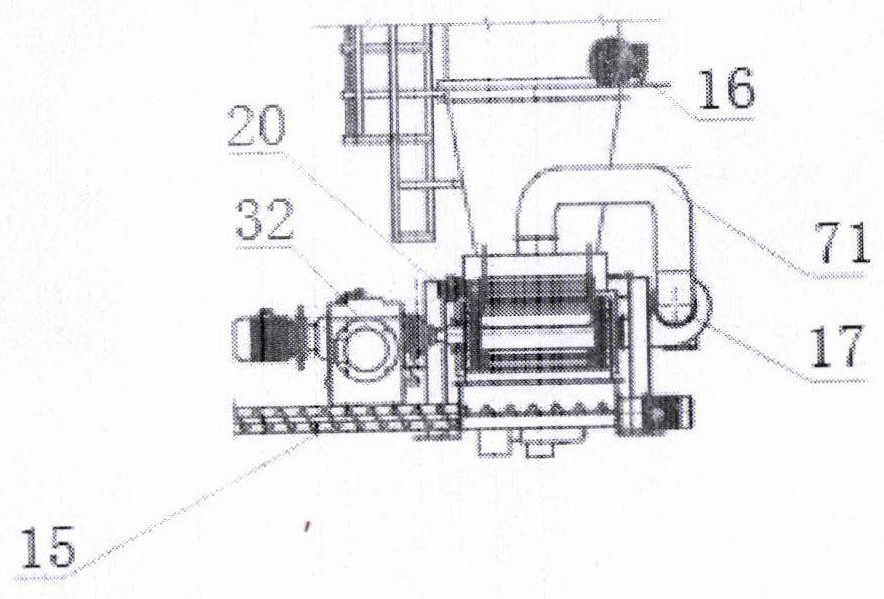

[0038] According to one embodiment of the present invention, the buried scraper machine 13 includes a scraper 31 , and a plurality of small holes are provided on the scraper 31 . A blower 14 is arranged at the bottom of the buried scraper machine 13, and the blower is arranged at the bottom of the scraper. During the discharging process, the blower 14 continuously sends cold air to the scraper 31 to take away the heat and cool down the material on the scraper 31 .

[0039] An induced draft fan 17 is also provided between the buried scraper machine 13 and the fermentation tower 11 , which is connected through an induced air pipe 71 . Since the blower 14 continuously sends cold air to the scraper 31, the heat will be continuously taken away. At this time, the excess heat can be led back into the fermentation tower 11 through the air duct 17 for fermentation of raw materials. This can not only recover and reuse heat, but also save energy and protect the environment.

[0040] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com