Twisting type shell breaking device for castanea henryi processing

A shell-breaking device and the technology of cone pump, which is applied in the field of kneading-type shell-breaking device for cone pump processing, can solve the problems of easily scratched hands, and achieve the effect of improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

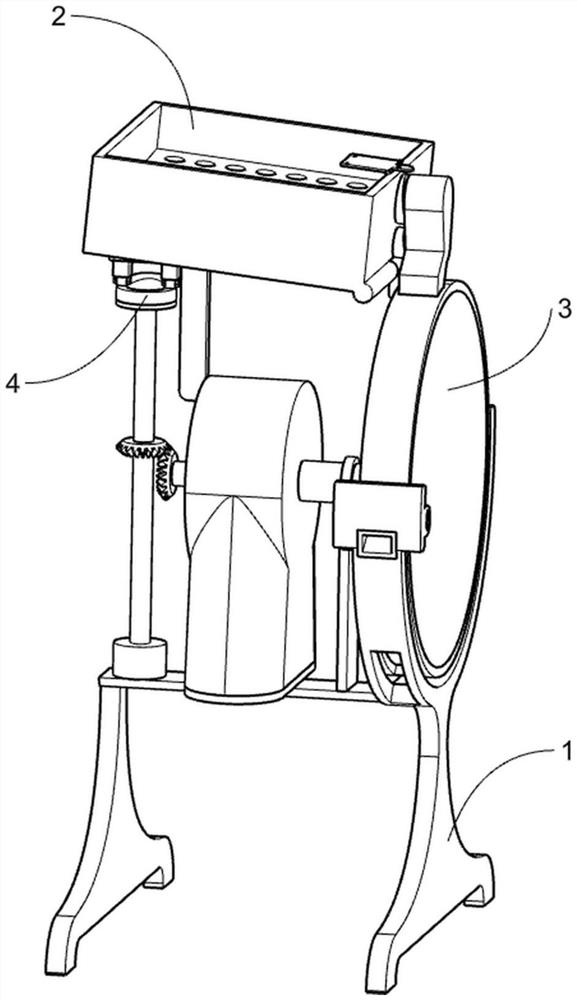

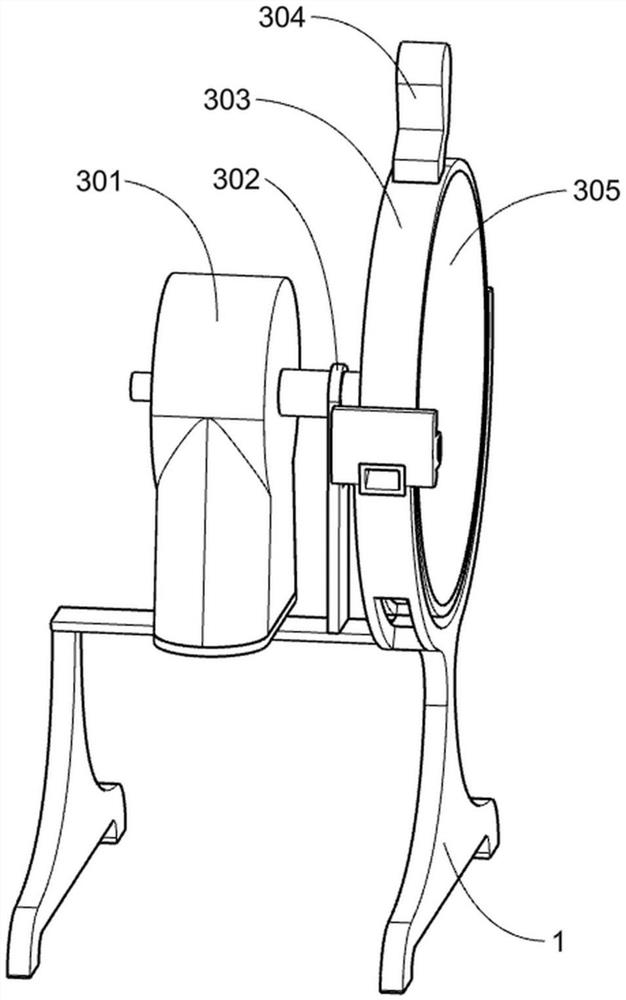

[0027] A kind of kneading type shell breaking device for cone pump processing, such as Figure 1-10 Shown, comprise frame 1, cone pump sieve box 2, cone pump shell breaking mechanism 3, shaking chassis mechanism 4 and wheel disc adjustment mechanism 5, one side of frame 1 is equipped with cone pump shell breaking mechanism 3, cone pump shell breaking mechanism 3, The pump shell-breaking mechanism 3 is used for breaking the shells of cone pumps by rubbing. One side of the cone pump shell-breaking mechanism 3 is equipped with a wheel adjustment mechanism 5. The wheel adjustment mechanism 5 is used for crushing the cone pumps of different sizes. A cone pump sieve box 2 is installed on the top of the cone pump shell breaking mechanism 3, and a shaker case mechanism 4 is installed on the other side of the frame 1, and the shake case mechanism 4 is used for sieving the cone pumps of different sizes.

[0028] When in use, the operator first pours the pumpkins that need to be broken i...

Embodiment 2

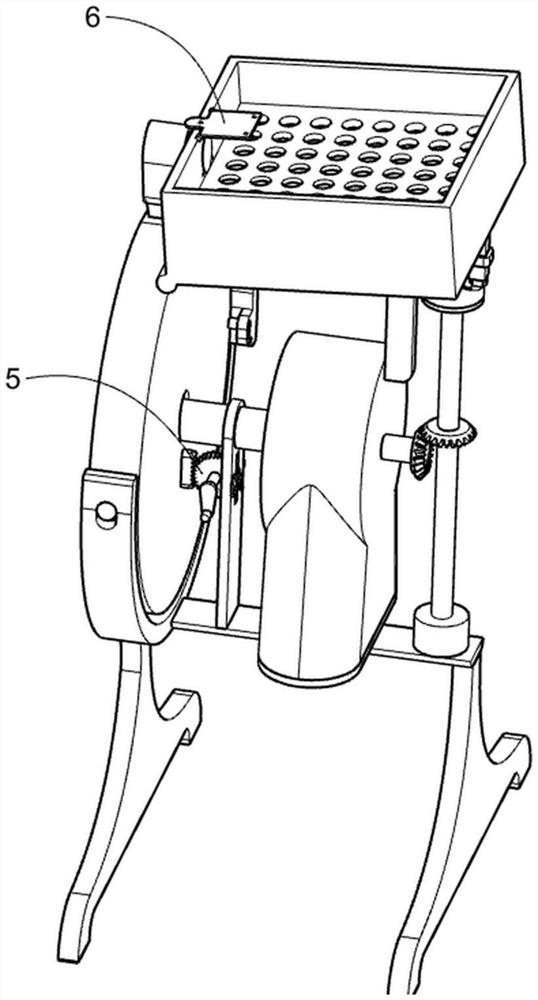

[0036] On the basis of Example 1, such as Figure 11-12 As shown, it also includes a cone pump separation mechanism 6, and the cone pump separation mechanism 6 is installed on the cone pump sieve box 2. The cone pump separation mechanism 6 includes a baffle plate 601 and a magnet 602, and the baffle plate 601 is rotatably connected. On one side of the cone pump screening box 2, the baffle plate 601 and the cone pump screening box 2 are all connected with a magnet 602.

[0037] When the operator turns down the baffle 601, the magnets 602 will be attracted to each other, and the position of the turned down baffle 601 will be fixed, so as to prevent the cone pump from slipping out of the cone pump sieve box 2 during the screening process. The lower baffle plate 601 can first crack the shells of the screened small chestnuts, so that the practicability of the equipment can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com