Fire-fighting lifting device for fire-fighting equipment

A fire-fighting equipment and lifting device technology, which is applied in fire rescue and other directions, can solve problems such as channel congestion, increased labor intensity, and unsafe operation, and achieve the effects of convenient movement, reduced labor intensity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

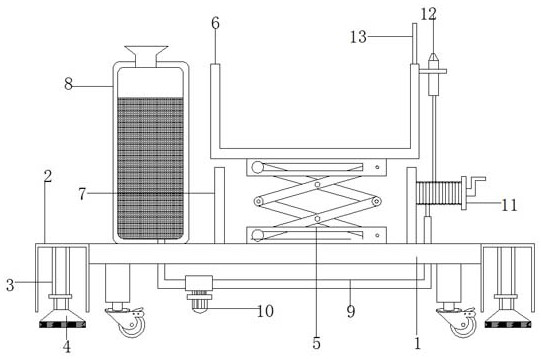

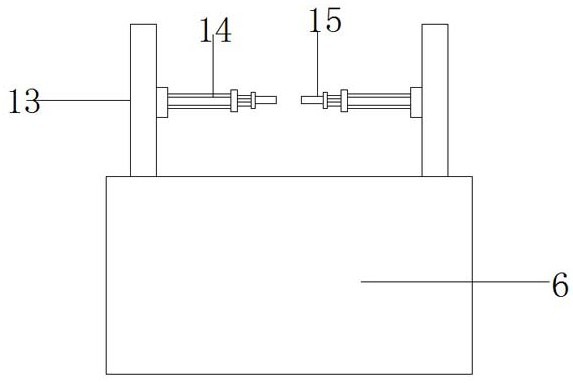

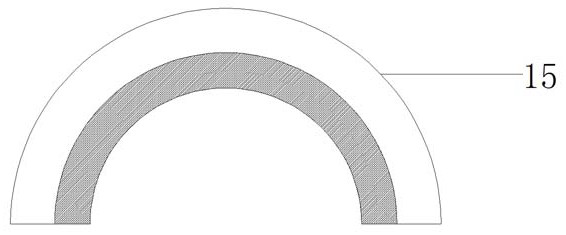

[0018] Embodiment 1, with reference to Figure 1-3 , a fire-fighting lifting device for fire-fighting equipment, including a base plate 1, an installation box 2 is welded on the outer walls of both sides of the base plate 1, and a hydraulic cylinder 3 is welded on the inner wall of the top of the installation box 2, and a support block 4 is welded at the end of the hydraulic cylinder 3 , the outer wall of the bottom of the support block 4 is welded with a non-slip mat, and the size of the anti-slip mat is compatible with the size of the support block 4, the outer wall of the top of the bottom plate 1 is welded with a lifting platform 5, and the top of the lifting platform 5 is welded with a support platform 6, supporting The platform 6 rises under the action of the lifting platform 5, and an appropriate height is selected according to the needs. At the same time, the supporting platform 6 protects the firefighters to prevent the firefighters from falling. The outer wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com