Forged piece clamping device suitable for forging machining

A technology of forging clips and grippers, applied in forging/pressing/hammer devices, manufacturing tools, metal processing equipment, etc., can solve the problems of operator difficulty in operation and smooth gripping of blanks, and achieve multi-angle operation, The effect of shortening the gripping distance and increasing the mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

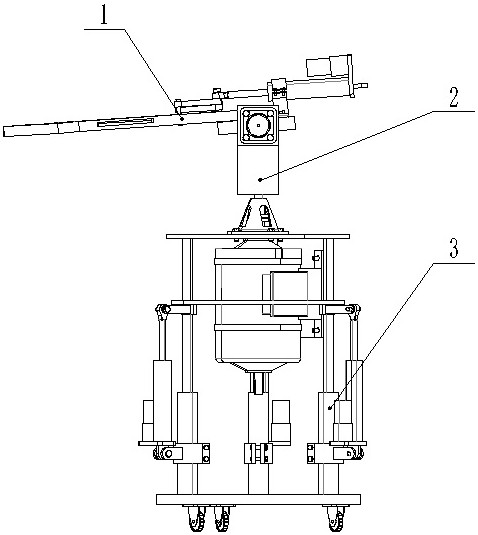

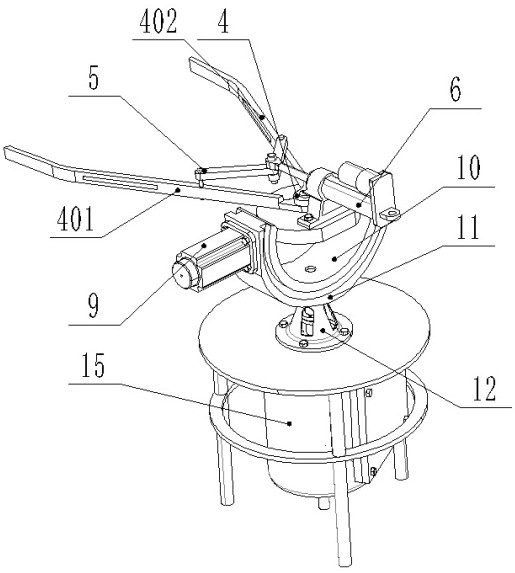

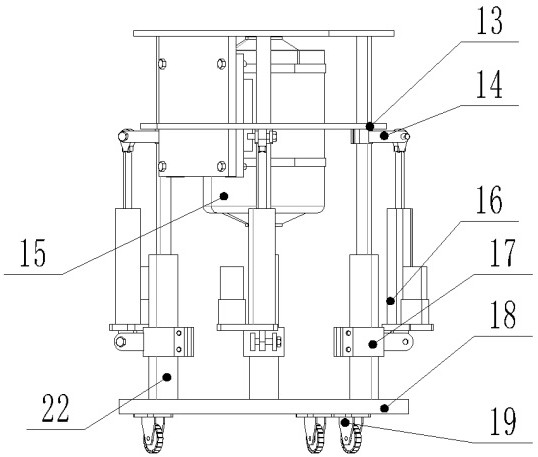

[0030] Example 1, such as Figure 1-5 As shown, a forging clamping device suitable for forging processing includes: a clamping mechanism 1, a rotating mechanism 2, and a lifting mechanism 3;

[0031] The gripping mechanism 1 includes: a gripper 4, a first push rod device 6;

[0032] The gripper 4 is provided with a first clamping arm 401 and a second clamping arm 402, which are hingedly fixed on the upper surface of the inner semi-circular ring device 10, and the first push rod device 6 is installed on the upper surface of the inner semi-circular ring device 10, for More stable and accurate grasping of forgings, the first push rod device 6 adopts the structure of electric cylinder or air cylinder, the first push rod device 6 is movably connected with the gripper 4 through the connecting rod 5, so as to realize the continuity of gripping ;

[0033] When the forging needs to be clamped, the first push rod device 6 is first started, and the telescopic rod in the first push rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com