Efficient 3D printing device based on visual inspection

A 3D printing and visual inspection technology, applied in the field of 3D printing, can solve the problems of small production volume, no application of automated production, high cost, etc., to achieve high production efficiency, improve the degree of automation, and ensure the effect of positioning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

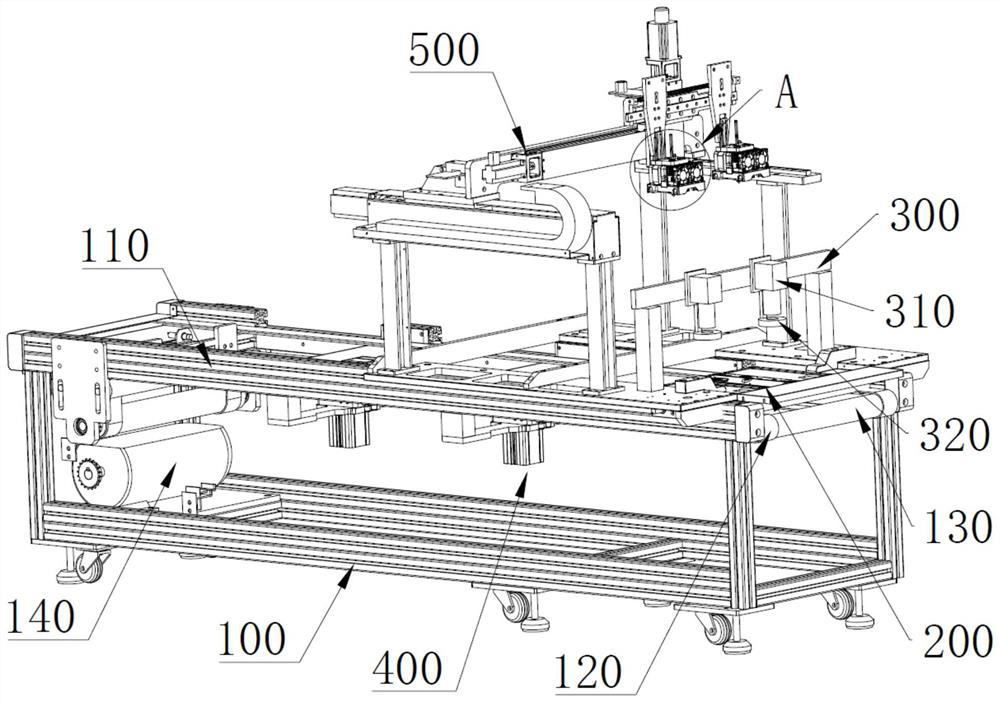

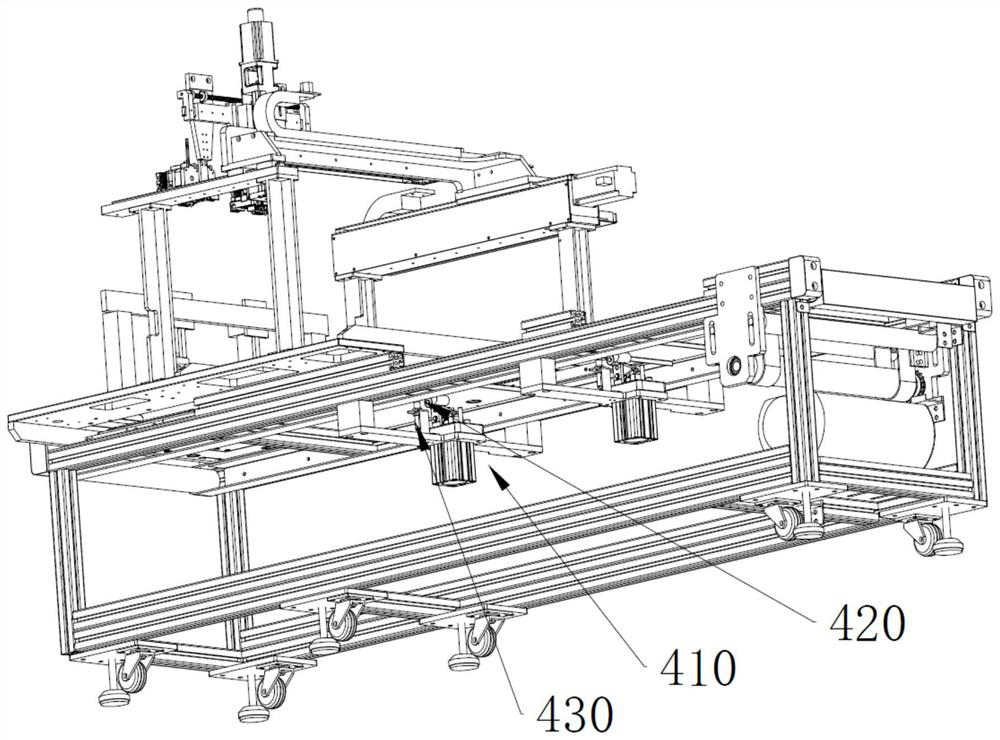

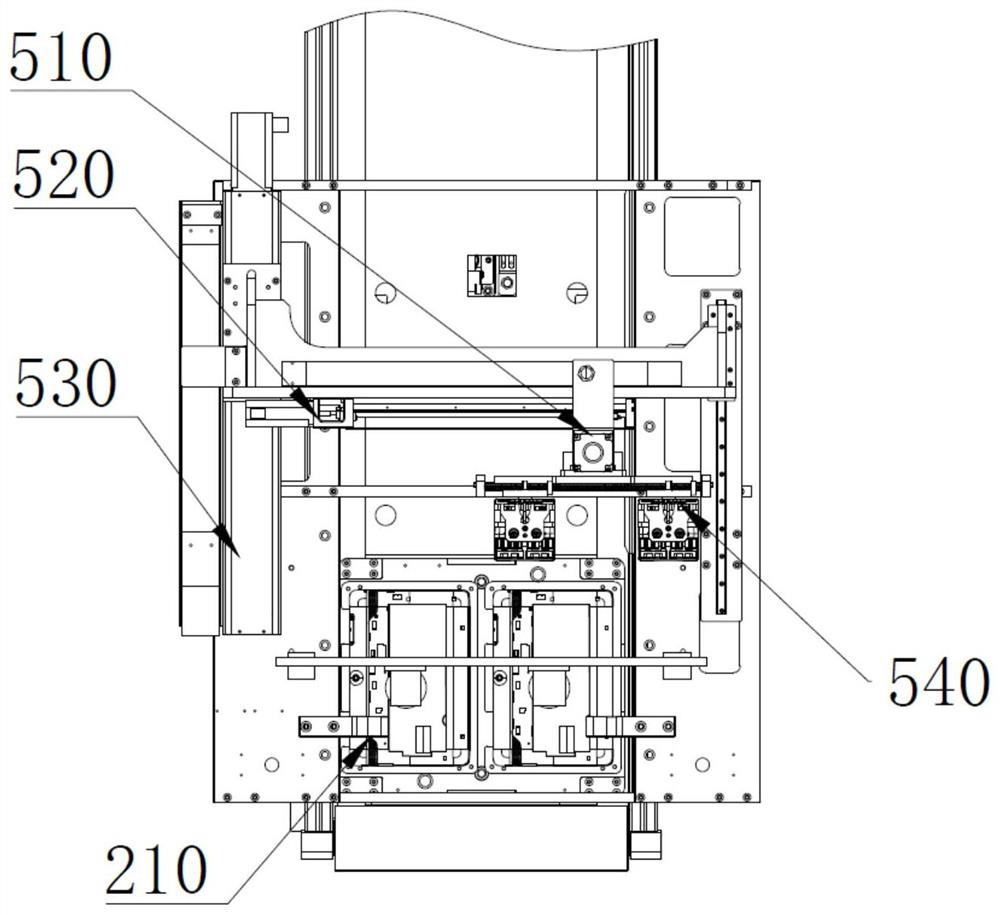

[0029] as attached Figure 1 to Figure 4 As shown, a high-efficiency 3D printing device based on visual inspection includes a conveying device 100, a conveying jig 200 transmitted to the conveying device 100 for fixing products, and is installed on the conveying device 100 to detect the vision of the product on the conveying jig 200. The detection device 300 is disposed on the conveying device 100 for positioning the conveying jig 200 as the positioning device 400 , and is used for the printing device 500 for correcting the positioning and printing.

[0030] The conveying device 100 comprises a conveying bracket 110, a conveying roller 120 mounted on the conveying carriage 110, a conveying belt 130 driven on the conveying roller 120, a driving motor 140 mounted on the conveying carriage 110 and conveying roller 120 drivingly connected, and the conveying jig 200 The tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com