Inkjet printing head cleaning device and cleaning method thereof

A technology of inkjet print head and cleaning device, which is applied in printing and other directions, can solve the problems of reducing production efficiency, reducing the service life of inkjet print head, increasing production cost, etc., so as to prolong the service life, alleviate the increase of cleaning frequency, and ensure The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

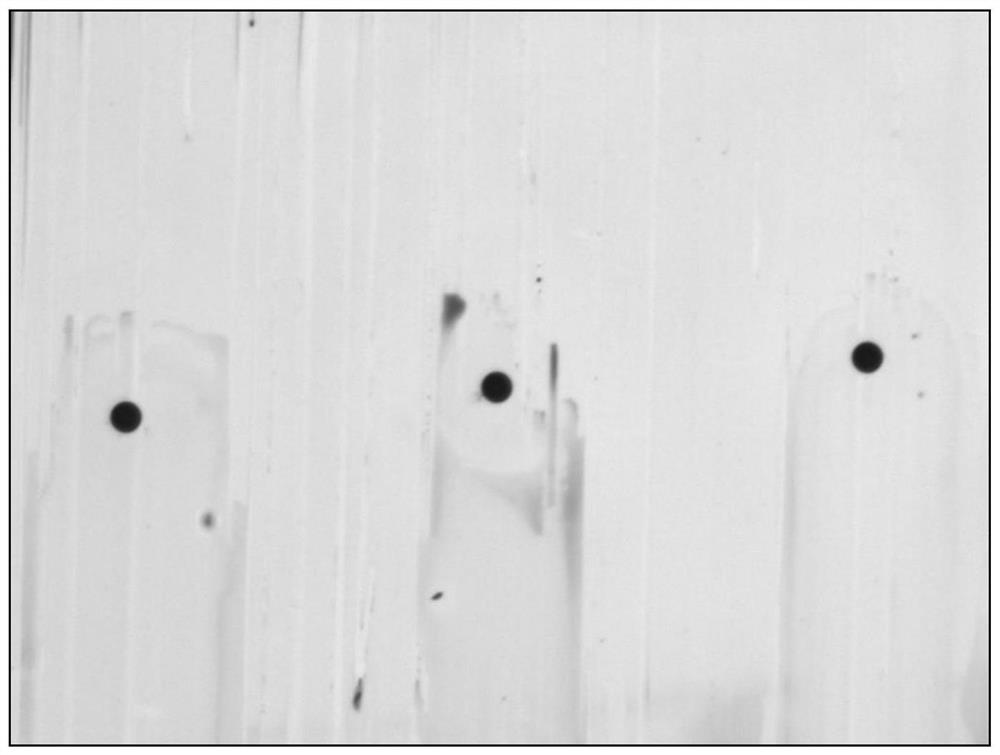

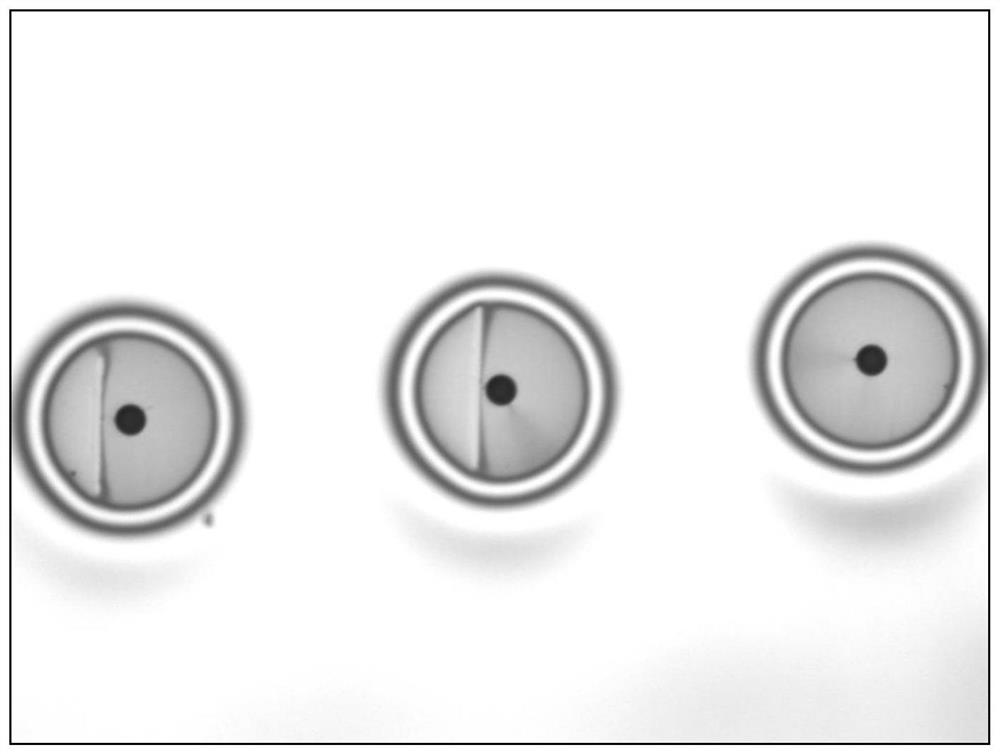

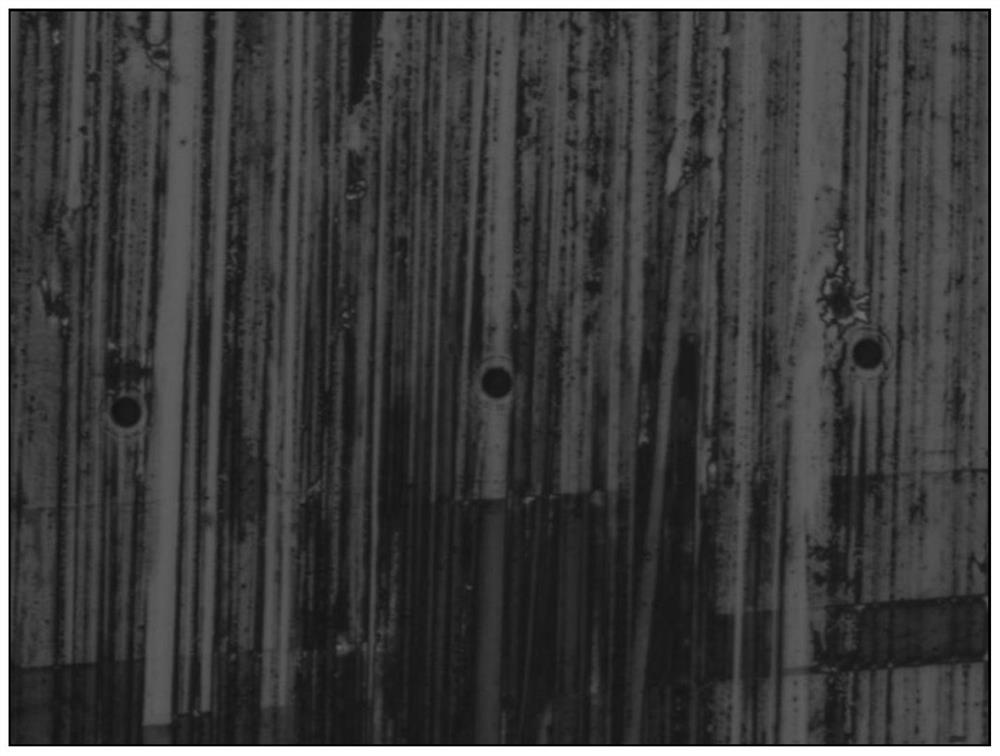

[0038] see image 3 As shown, this embodiment provides an inkjet printing head cleaning device 10 .

[0039] The inkjet print head cleaning device 10 includes a cleaning tank 100 and a solvent vapor generator 200 . The cleaning tank 100 is used for supplying the first solvent (attached image 3 , 4 shown in A) in full bloom. Solvent steam generator 200 is installed on the cleaning tank 100, and the nozzle of solvent steam generator 200 faces in the cleaning tank 100, and solvent steam generator 200 is used for forming the second solvent into solvent vapor (attached image 3 , 4 shown in B) and ejected from the nozzle. During cleaning, the first solvent is the carrier solvent of the printing ink after the solute is removed, and the first solvent is the same as the solvent component of the ink used by the print head during inkjet printing. The surface tension of the second solvent is smaller than the surface tension of the first solvent.

[0040] When cleaning the print h...

Embodiment 2

[0051] This embodiment provides a method for cleaning an inkjet printing head.

[0052] The inkjet printing head cleaning method comprises the steps:

[0053] (1) Cleaning by immersing the print head 20 in a first solvent, the first solvent is the same as the solvent composition of the ink used by the print head during inkjet printing.

[0054] (2) The second solvent is formed into a solvent vapor and sprayed parallel to the liquid surface direction of the first solvent, and the surface tension of the second solvent is smaller than that of the first solvent. The second solvent is at least one of isopropanol, ethanol, methanol, n-octane, n-hexane and acetone.

[0055] (3) Rotate the print head 20 so that its nozzle plane 21 forms an acute angle with the liquid surface of the first solvent, and the acute angle α (such as image 3 shown) is 20°-30°, and the opening at the acute angle faces the direction of solvent vapor ejection.

[0056] (4) The print head 20 moves along the ...

Embodiment 3

[0060] This embodiment provides a method for cleaning an inkjet printing head.

[0061] The inkjet printing head cleaning method comprises the steps:

[0062] (1) The print head 20 is immersed in a first solvent, which is the same as the solvent composition of the ink used by the print head during inkjet printing. The print head 20 is cleaned by ultrasonic treatment. The vibration frequency of ultrasonic treatment is 20kHz-50kHz, and the power density is 0.3W / cm 2 Above, the cleaning time is 180s-300s.

[0063] (2) The second solvent is formed into a solvent vapor and sprayed parallel to the liquid surface direction of the first solvent, and the surface tension of the second solvent is smaller than that of the first solvent. The second solvent is at least one of isopropanol, ethanol, methanol, n-octane, n-hexane and acetone.

[0064] (3) Rotate the printing head 20 so that the nozzle plane 21 forms an acute angle with the liquid surface of the first solvent, the acute angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com