Wuji oral liquid filling equipment

A technology of black-bone chicken oral liquid and filling equipment, which is applied in liquid bottling, packaging, liquid treatment, etc., can solve problems such as low production efficiency, unfavorable production and development of enterprises, and waste of black-bone chicken oral liquid, so as to improve work efficiency and save Manpower, the effect of reducing manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

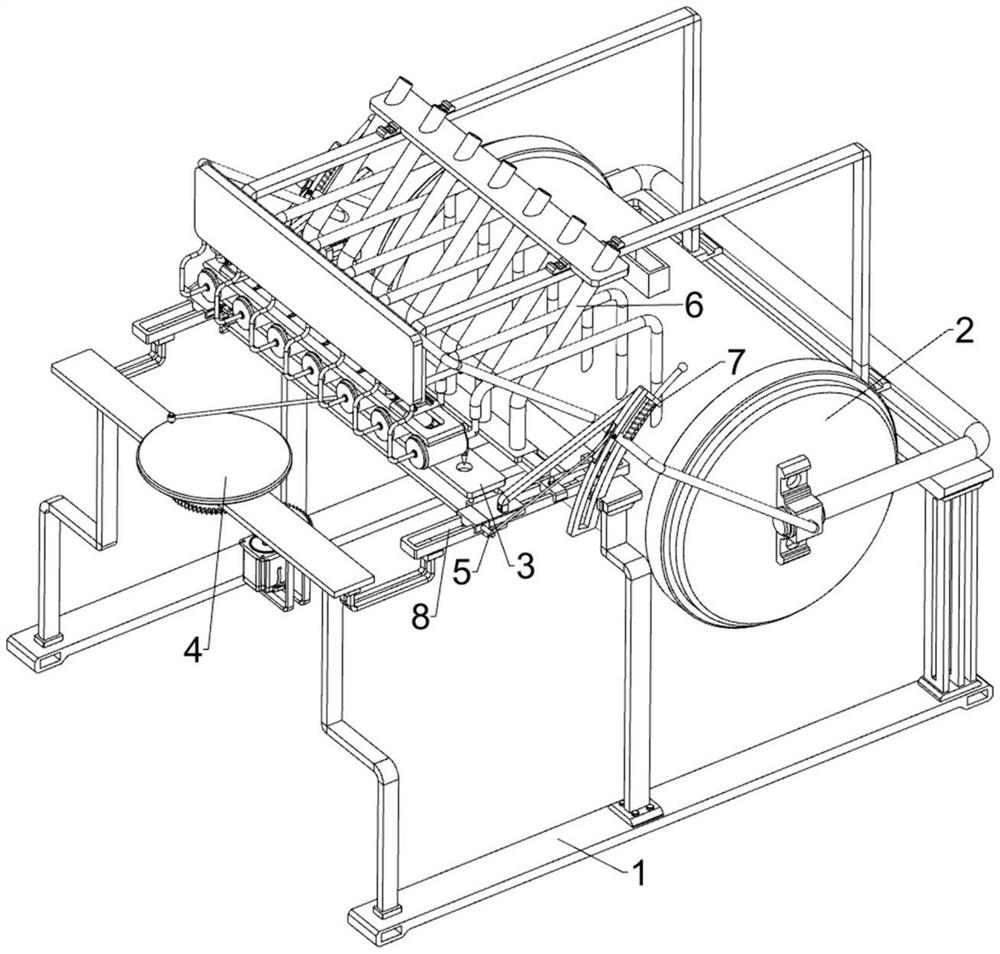

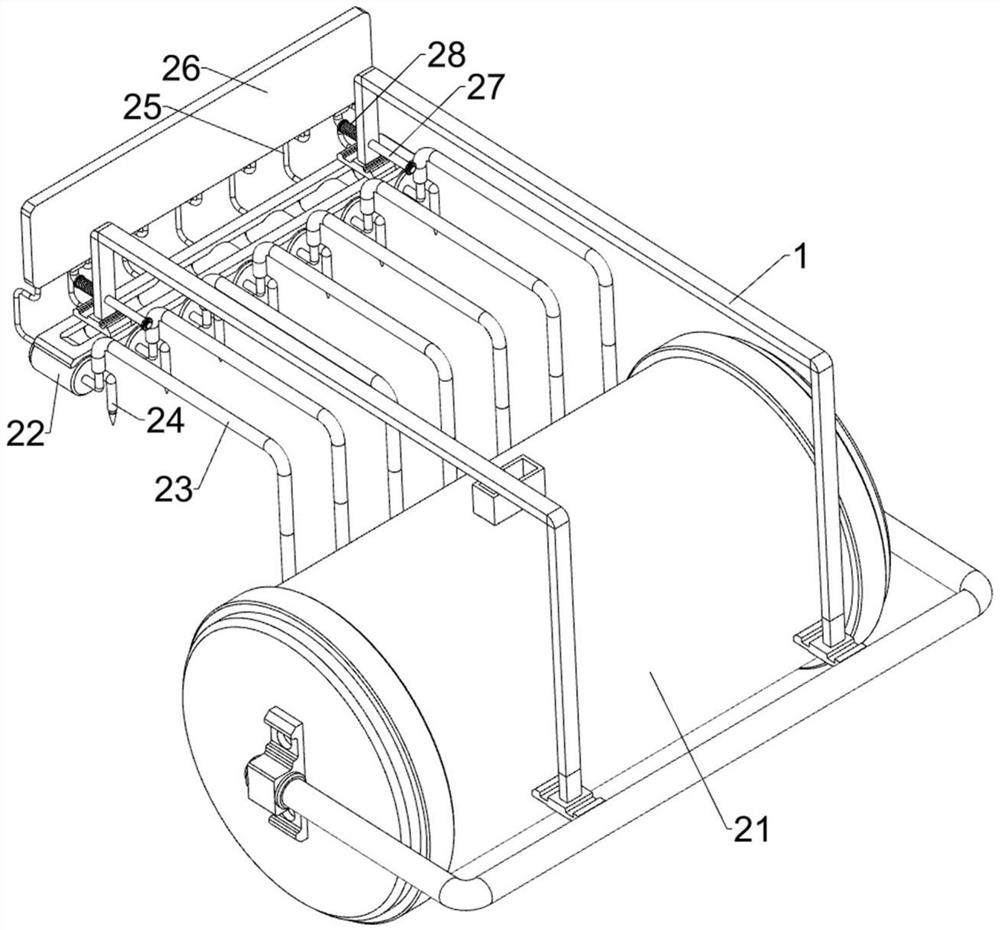

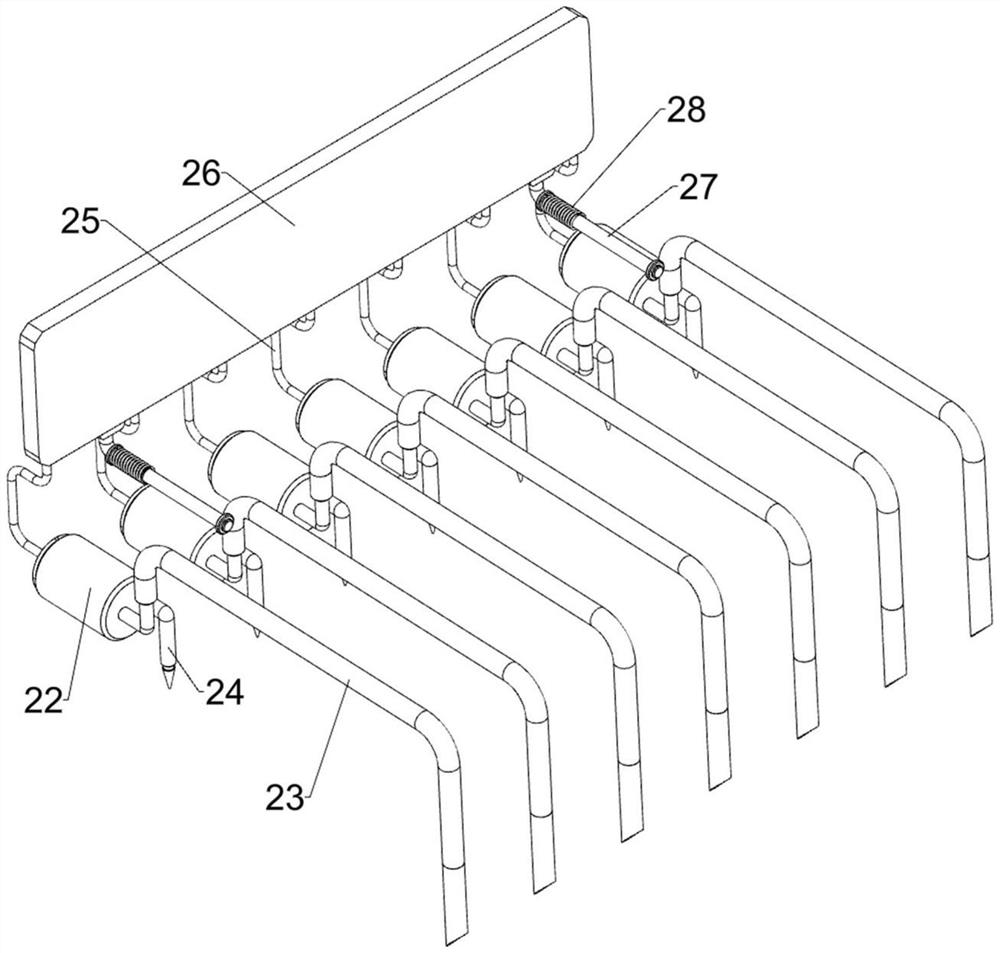

[0032] A black-bone chicken oral liquid filling equipment, such as Figure 1 to Figure 6 As shown, it includes a bracket 1, a material pumping and spraying component 2, a placement component 3 and a push-pull component 4. The bracket 1 is provided with a pumping and spraying component 2, and the bracket 1 is provided with a placement component 3. Push-pull components 4 are arranged between the components 3 .

[0033] When it is necessary to fill the black-bone chicken oral liquid, the bottle of the black-bone chicken oral liquid is placed on the placement component 3, and then the pumping and spraying component 2 is controlled to operate, so that the pumping and spraying component 2 pours the black-bone chicken oral liquid into the bottle, then start the push-pull assembly 4, the push-pull assembly 4 will drive the placement assembly 3 to move, and then the black-bone chicken oral liquid can be taken out from the placement assembly 3 after filling, and then the bottle of the b...

Embodiment 2

[0041] On the basis of Example 1, such as figure 1 , Figure 7 , Figure 8 , Figure 9 , Figure 10 with Figure 11 As shown, it also includes a blanking assembly 5, the blanking assembly 5 includes a limit block 51, a guide sleeve 52, a first L-shaped guide rod 53, a second spring 54 and a fixed stop 55, the front and rear sides of the slide plate 35 are all The limit block 51 is welded, the front and rear sides of the bottom of the slide plate 35 are provided with guide sleeves 52, the left side of the second slider 34 is welded with a first L-shaped guide rod 53, the first L-shaped guide rod 53 and the guide sleeve 52 Sliding connection, the second spring 54 is connected between the first L-shaped guide rod 53 and the guide sleeve 52, the lower side of the slide rail 31 is provided with a fixed stop 55, and the fixed stop 55 cooperates with the limit block 51 .

[0042] When the placement frame 33, the second slide block 34 and the slide plate 35 moved to the left, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com