Scale inhibition device for cooking equipment and control method thereof

A technology for cooking equipment and scale inhibition, applied in the field of cooking equipment, can solve problems such as blocked waterways, consumer health hazards, steam box failure, etc., and achieve the effects of extending service life, improving work efficiency and steam quality, and protecting health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

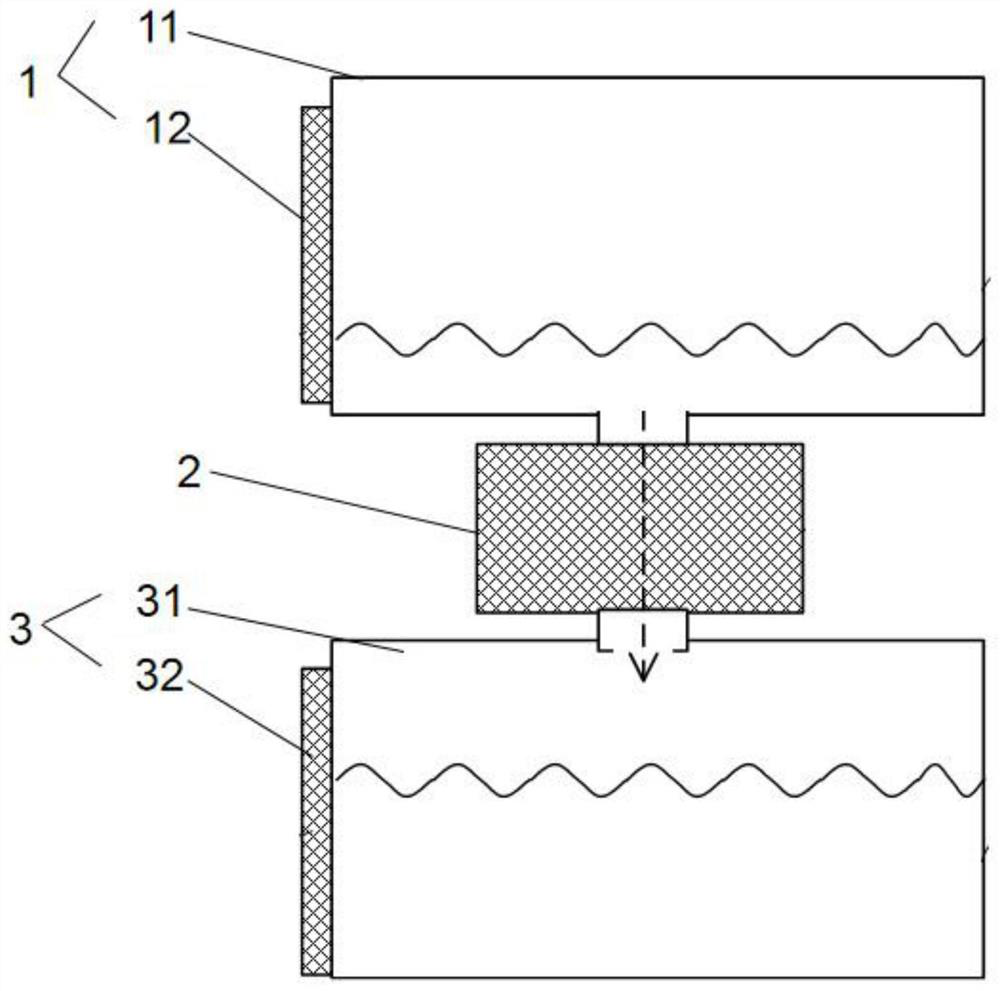

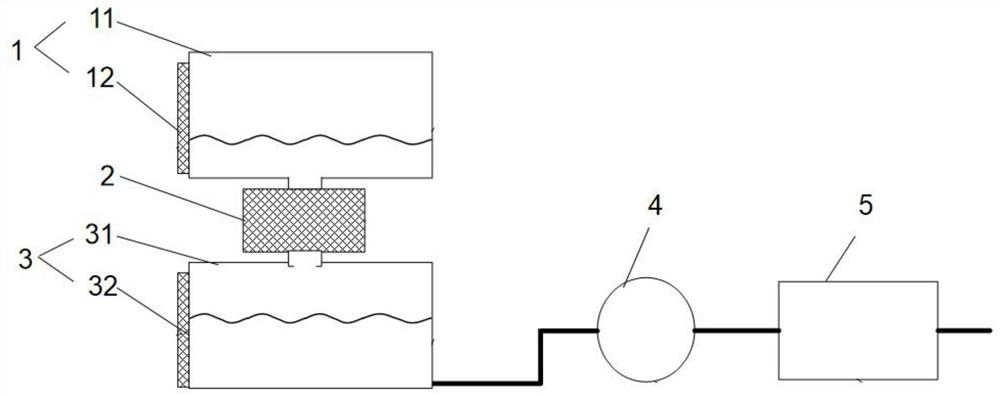

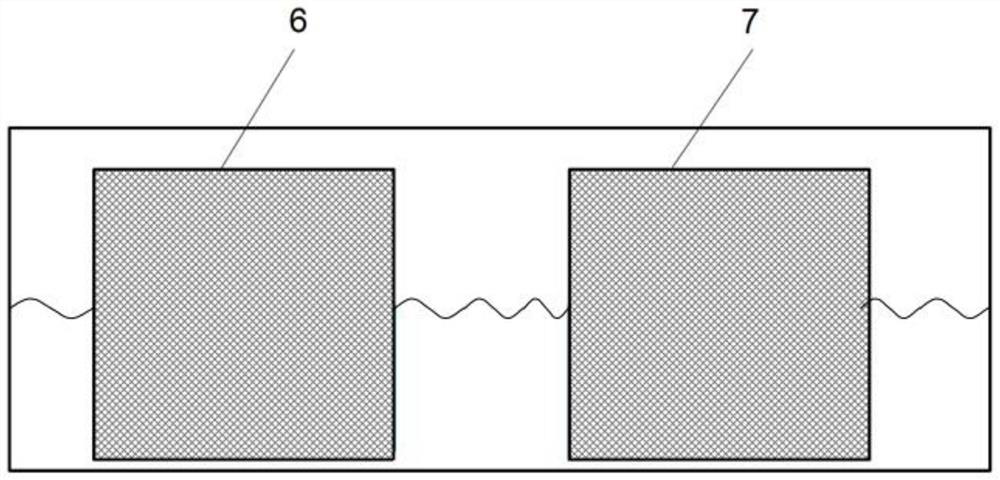

[0030] Embodiment 1 of the present invention provides a scale prevention device for cooking equipment, such as Figure 1-3 As shown, it includes a raw water component 1 provided with a first water level monitoring device, a scale prevention component 2, and a pure water component 3 provided with a second water level monitoring device, and the scale prevention component 2 is arranged below the raw water component 1 for the raw water. For scale inhibition, the pure water component 3 is arranged under the scale inhibition component 2 for receiving pure water obtained after scale inhibition.

[0031] In this way, the antiscaling component 2 is arranged under the raw water component 1 for antiscaling the raw water, and the pure water component 3 is arranged under the antiscaling component 2 for receiving the pure water obtained after the antiscaling, so that it can be used for cooking Scale inhibition and filtration of the raw water before the equipment is used to obtain pure water...

Embodiment 2

[0054] Such as Figure 4 As shown, Embodiment 2 of the present invention provides a control method based on the antiscaling device for cooking equipment, including the following steps:

[0055] S1. Inject tap water into the raw water component, record each water level change through the first water level monitoring device to calculate the total water volume, compare the total water volume with the preset filtered water volume of the anti-scaling component, and determine whether to prompt replacement according to the comparison result anti-scaling components;

[0056] S2. Record the water level value in the pure water component through the second water level monitoring device, compare the water level value in the pure water component with the preset prompt water level value, and determine whether to prompt water shortage according to the comparison result.

[0057] In this way, the total water quantity Q is calculated by recording each water level change by the first water lev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com