Cream coating machine

A coating machine and cream technology, applied in the direction of textiles and papermaking, fiber raw material processing, sending objects, etc., can solve the problems of reducing work efficiency, unable to meet large batches and large areas of coating, time-consuming and manpower, etc., to achieve liquid Increased viscosity range, flexible processing methods, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

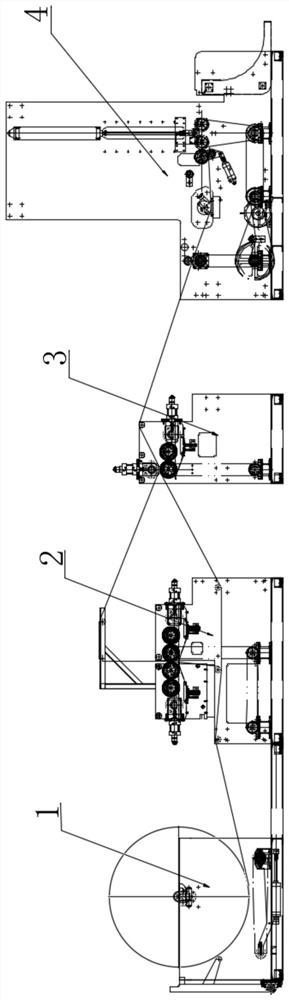

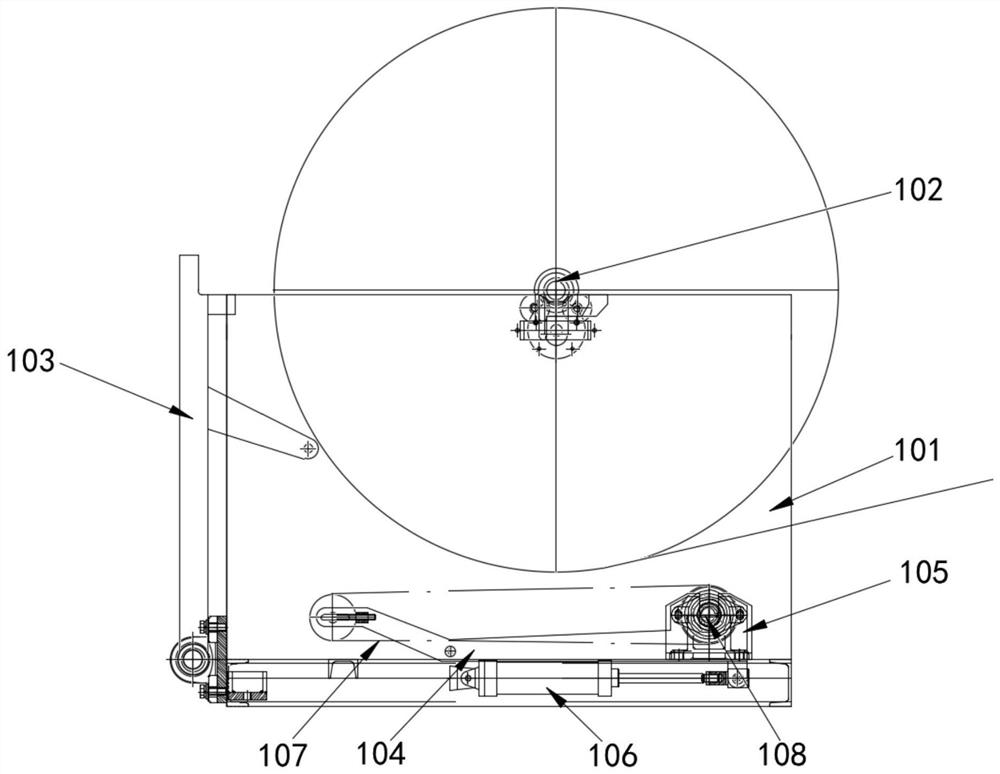

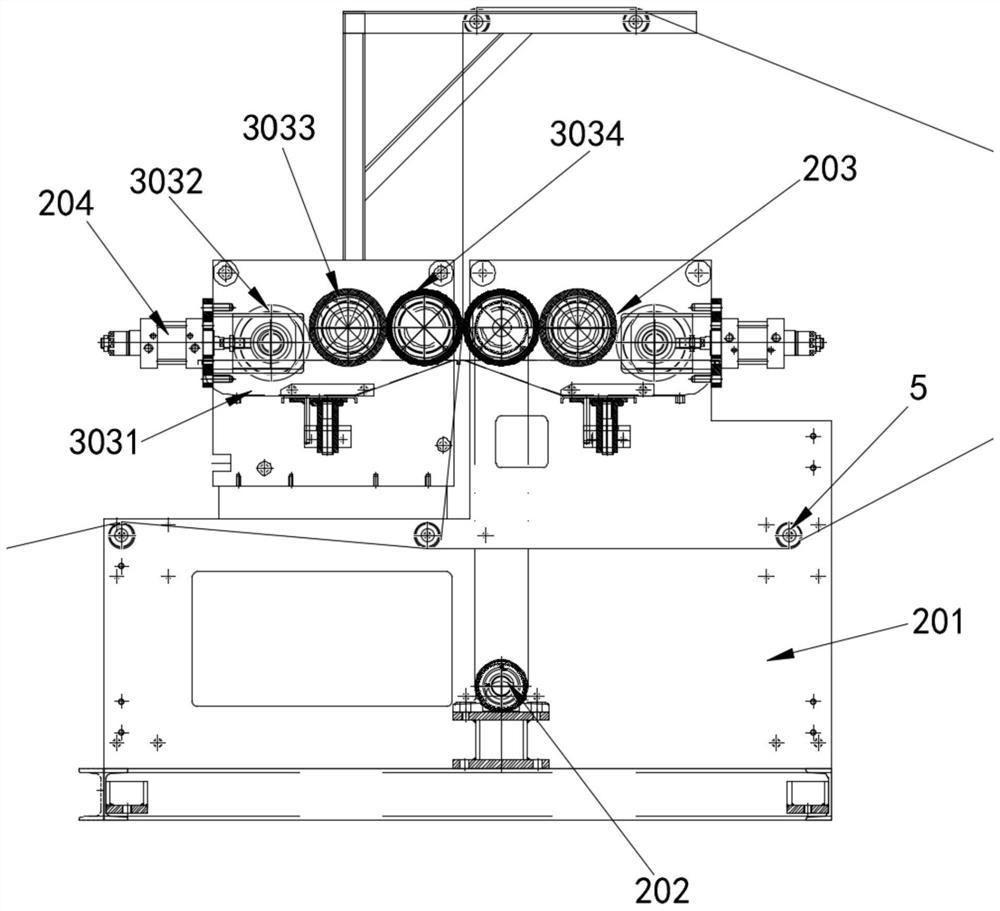

[0021] refer to Figure 1-5, the technical solution adopted in the present invention is: a kind of cream coater, comprises base paper machine 1, double-deck roll coater 2, single-layer roll coater 3, winding machine 4 arranged in sequence, and described base paper machine comprises The first frame 101, a base paper roll 102 for winding paper towels, a paper lifting frame 103 and a paper feeding mechanism 104, the paper lifting frame 103 is located at the front end of the first frame 101 and is used to complete the paper towel clamping and jacking, the paper feeding mechanism 104 includes a push bracket 105 and an adjustment cylinder 106, the push bracket 105 is slidably arranged at the bottom of the first frame 101, and the push bracket 105 is provided with Circularly rolling conveyor belt 107, one end of the push bracket 105 is provided with a first drive motor 108, and the first drive motor 108 drives the conveyor belt 107 to rotate, and one end of the adjustment cylinder 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com