Prefabricated vertical component and sleeve grouting construction method thereof

A technology for vertical components and construction methods, which is applied to building components, structural elements, building reinforcements, etc., can solve the problems of insufficient sleeve grouting fullness, dangerous buildings, and hidden safety hazards, and achieves fully qualified construction quality and safety requirements. requirements, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

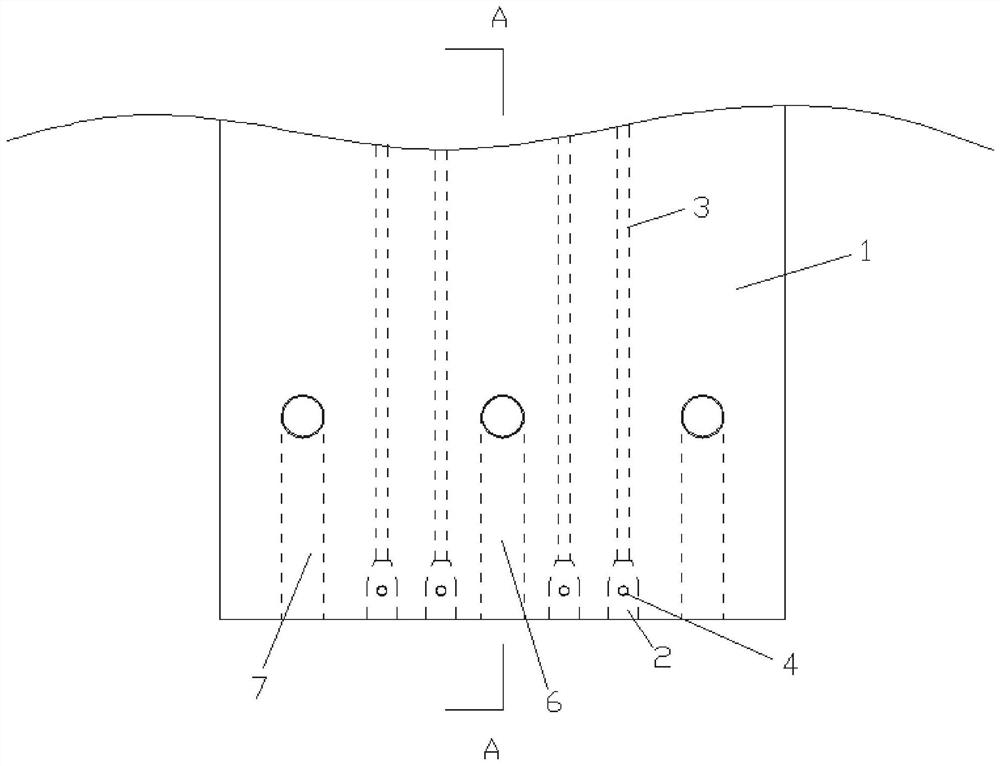

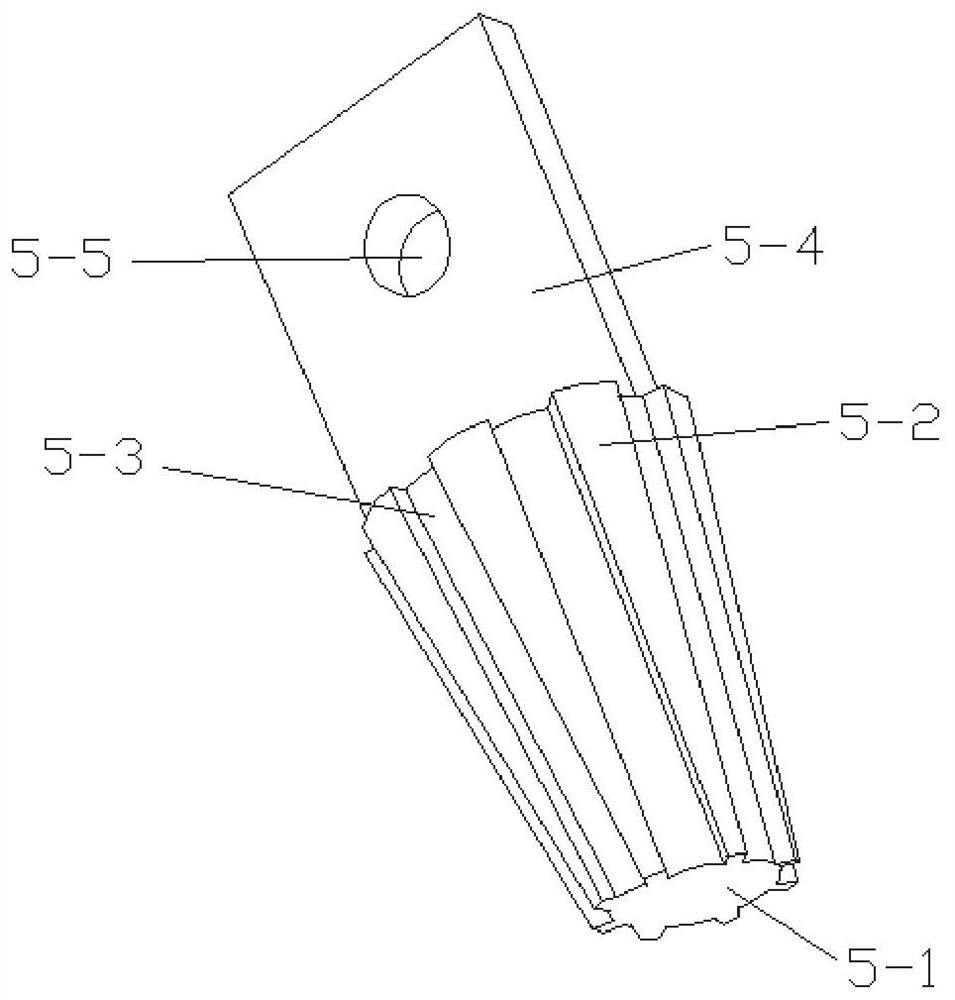

[0047] This embodiment discloses a sleeve grouting construction method for the prefabricated component described in Embodiment 1, and the prefabricated vertical component is a prefabricated wallboard as an example for illustration.

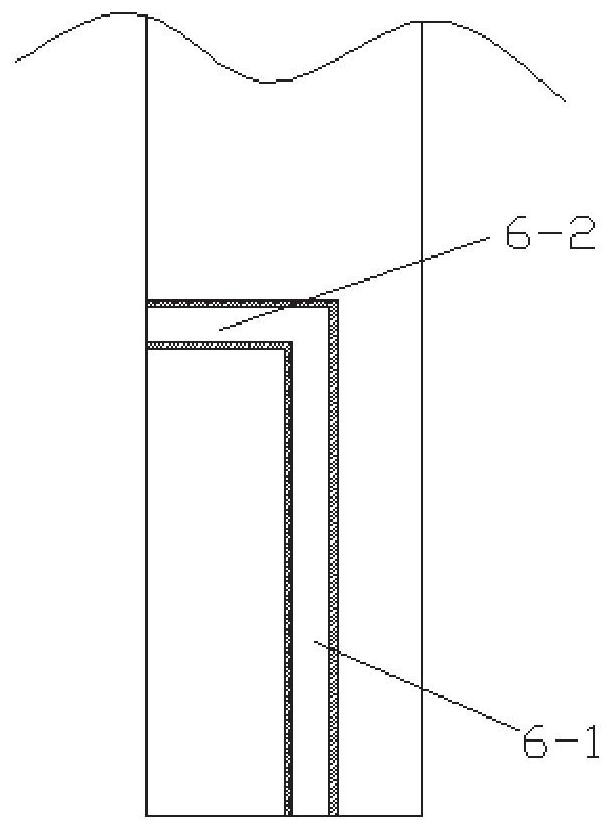

[0048] Such as Figure 4-Figure 5 As shown, the prefabricated wall panel is hoisted to the set position, and the steel bars of the components used to connect with the prefabricated wall panel under the prefabricated wall panel extend into the pre-embedded grouting sleeve in the prefabricated wall panel. The grout sealing material is constructed at the corresponding position of the wallboard as the slurry sealing structure 9 of the grouting layer 8 below the wallboard, and the slurry sealing structure forms the cavity structure of the grouting layer, and the components used to connect with the prefabricated wallboard It can be floor, wall or column etc.

[0049] The above-mentioned methods all adopt the existing construction method of the grouting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com