Automatic corrosion simulation testing machine device

A simulation test and dressing technology, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problem of consuming a lot of time and manpower, and achieve high practicability, easy installation, saving time and manpower and material resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

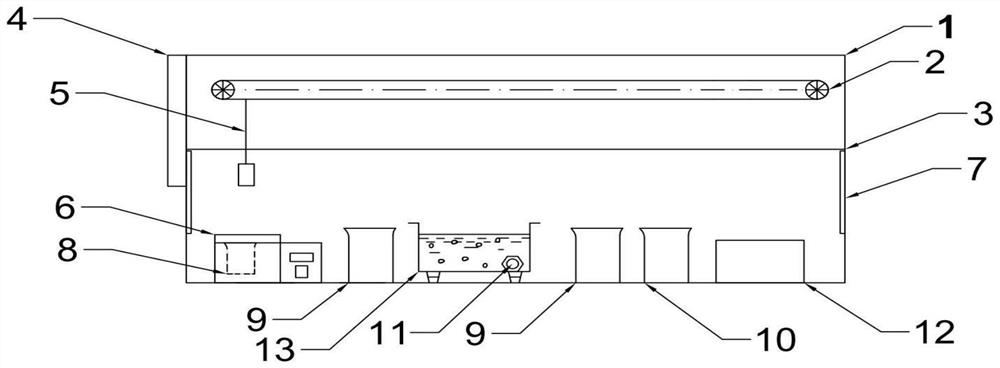

[0020] Such as figure 1 Shown, a kind of automatic corrosion simulation testing machine device provided by the present invention, 1 casing top half is guide rail, and is suspended with 7 heating pipes; The bottom half includes 6 water baths; 8 beakers 1; 9 beakers 2; 10 beakers 3; 11 peristaltic pump; 12 drying device; 13 ultrasonic cleaner; 4 control panels are attached to the outside of the box.

[0021] The peristaltic pump 11 is used to pump out the pickling liquid to prevent the internal mechanism from evaporating and corroding the pickling liquid. Its advantages include high precision, good sealing, and simple maintenance.

[0022] The present invention includes the following three working modes:

[0023] 1) Immersion mode. Hang the sample on the end of the wire, select the soaking mode through the control panel, set the soaking cycle and te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com