Active Material Ball Composite Layer

A technology of active material and composite layer, applied in the field of composite layer, can solve problems such as depletion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

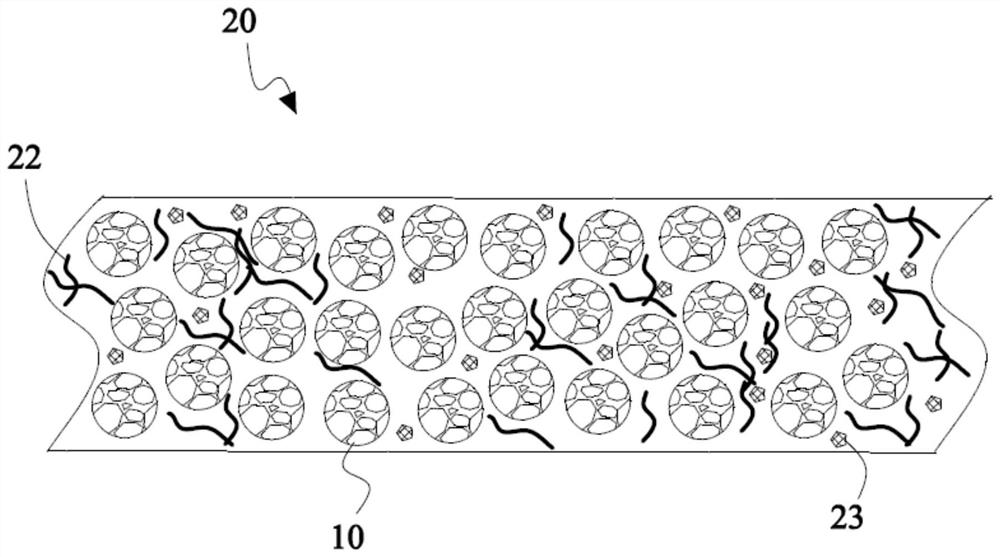

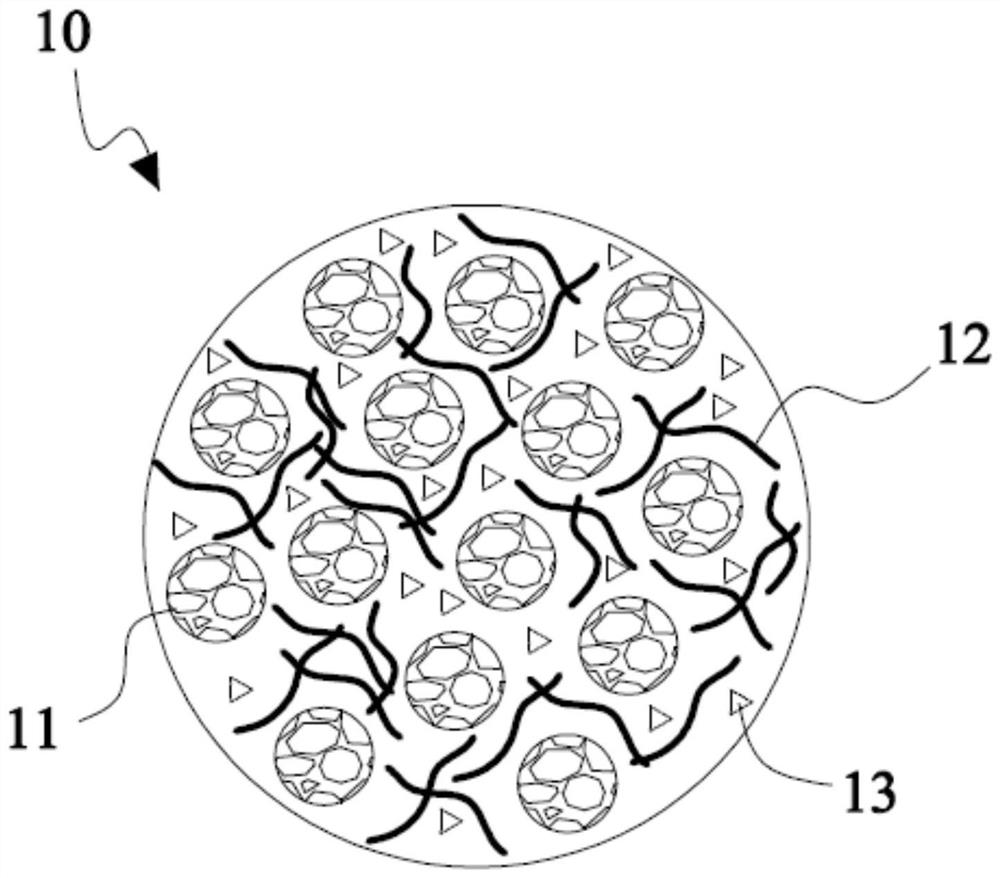

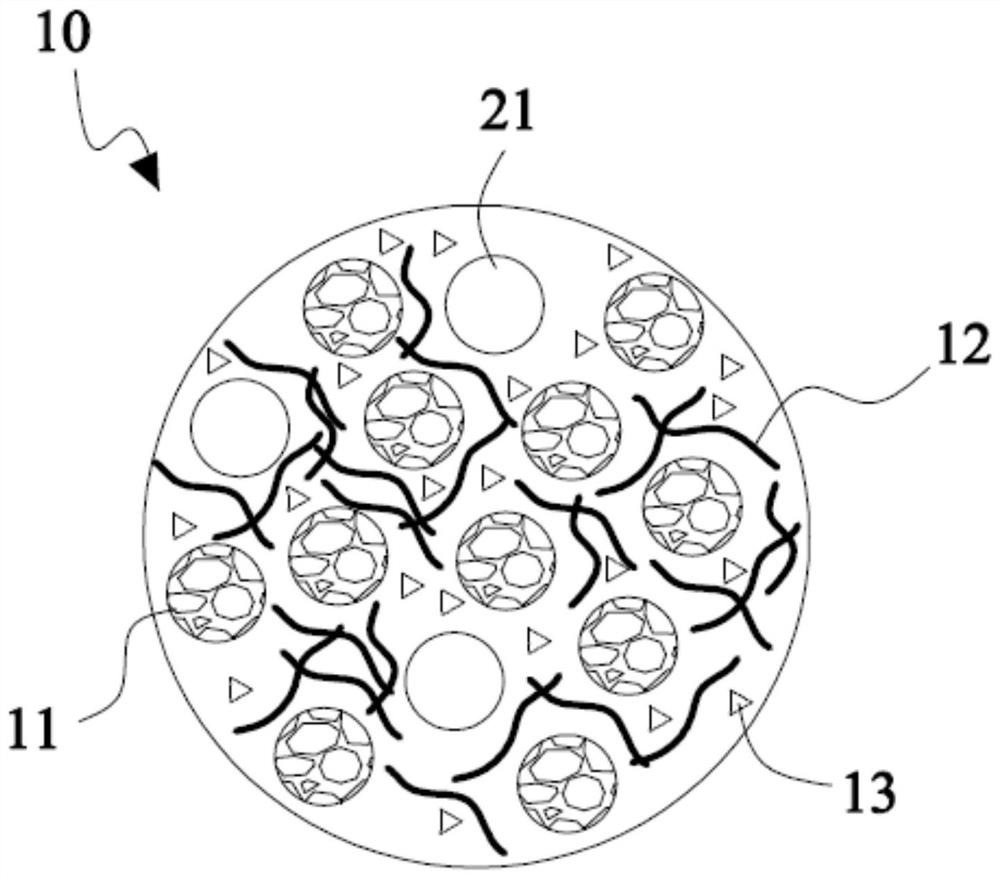

[0029] Please also refer to figure 1 and figure 2 , each of which is a schematic diagram of the composite layer of active material spheres and a schematic structural diagram of the active material spheres provided by the embodiments of the present invention. The active material sphere composite layer 20 disclosed in the present invention is mainly composed of several preformed active material spheres 10 , an external adhesive 23 and a second conductive material 22 . The preformed active material ball 10 mainly includes a plurality of first active material particles 11 , a first conductive material 12 and an internal adhesive 13 . The range of median diameter D50 of this first active material particle 11 is no more than 60% of the diameter of active material ball 10, for example, when the diameter of active material ball 10 is 50-60 microns, the first active material particle 11 The median particle size D50 range will be within 30 to 36 microns. The first active material pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com