A kind of fluorine gypsum-based interior wall plastering material and its production process

A production process and technology of fluorine gypsum, applied in the field of building materials, can solve the problems of slow condensation rate at low temperature, poor volume stability, low strength, etc., and achieve the effects of fast hydration rate, stable volume and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

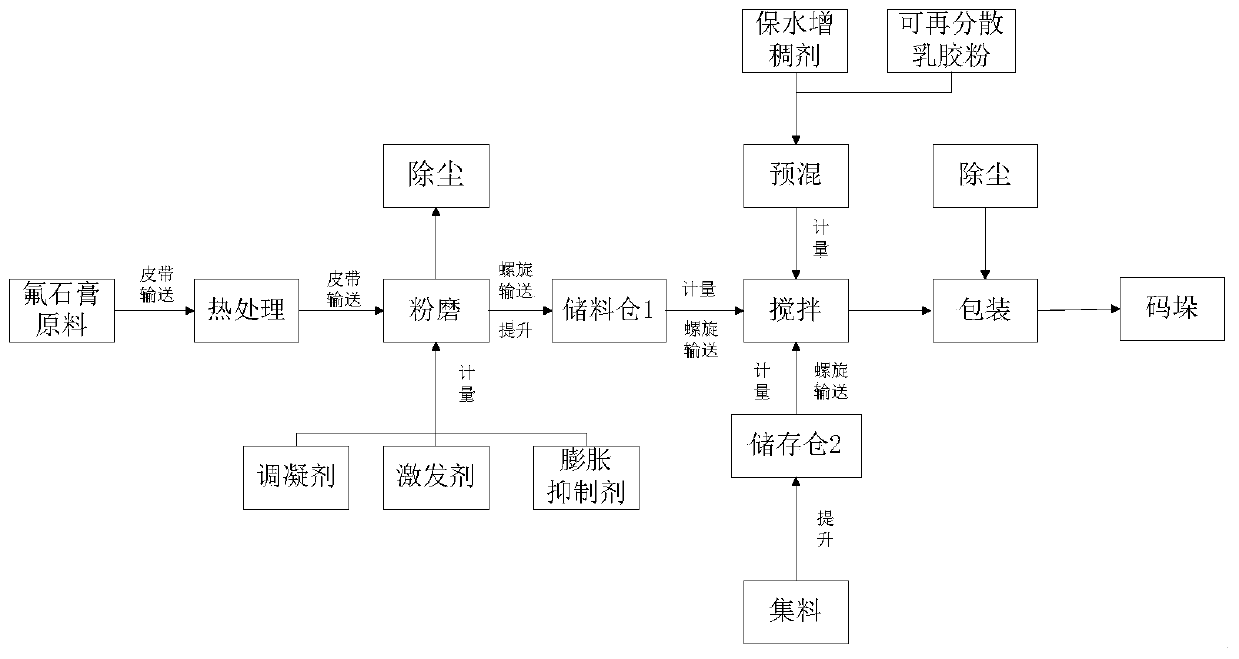

Method used

Image

Examples

Embodiment 1

[0080] The fluorogypsum-based interior wall plastering material prepared in the embodiment of the present invention is uniformly mixed by the following components in weight percentage: 8800 parts of fluorogypsum raw material, 800 parts of expansion inhibitor, 200 parts of activator, 200 parts of setting modifier, 0 parts of aggregate, 20 parts of water retention thickener and 50 parts of redispersible latex powder.

[0081] First, the raw material of fluorogypsum is subjected to low temperature heat treatment, and then ground together with expansion inhibitor, activator and coagulant to obtain modified fluorogypsum. Finally, modified fluorogypsum, aggregate, water-retaining thickener and redispersible latex are mixed The fluorine gypsum-based interior wall plastering material can be obtained by stirring the powder evenly.

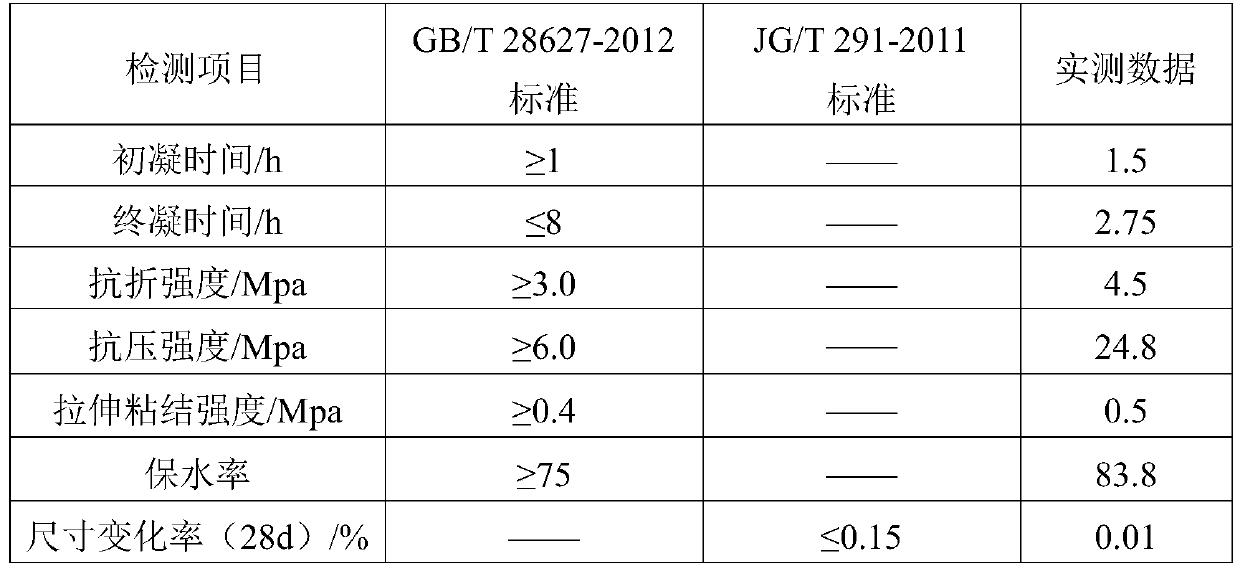

[0082] During construction, the fluorine gypsum-based interior wall plastering material was added with water at a water-cement ratio of 0.35 and stirred ev...

Embodiment 2

[0087] The fluorogypsum-based interior wall plastering material prepared in the embodiment of the present invention is uniformly mixed by the following components in percentage by weight: 8600 parts of fluorogypsum raw material, 300 parts of expansion inhibitor, 150 parts of activator, 250 parts of setting modifier, 5000 parts of aggregate, 50 parts of water-retaining thickener, and 100 parts of redispersible latex powder.

[0088] First, the raw material of fluorogypsum is subjected to low temperature heat treatment, and then ground together with expansion inhibitor, activator and coagulant to obtain modified fluorogypsum. Finally, modified fluorogypsum, aggregate, water-retaining thickener and redispersible latex are mixed The fluorine gypsum-based interior wall plastering material can be obtained by stirring the powder evenly.

[0089] During construction, the fluorine gypsum-based interior wall plastering material was mixed with water at a water-cement ratio of 0.29, and t...

Embodiment 3

[0094] The fluorogypsum-based interior wall plastering material prepared in the embodiment of the present invention is uniformly mixed with the following components in percentage by weight: 8000 parts of fluorogypsum raw material, 150 parts of expansion inhibitor, 200 parts of fluorogypsum activator, and 400 parts of coagulant. parts, 12,000 parts of aggregate, 80 parts of water-retaining thickener, and 200 parts of redispersible latex powder.

[0095] First, the raw material of fluorogypsum is subjected to low temperature heat treatment, and then ground together with expansion inhibitor, activator and coagulant to obtain modified fluorogypsum, and finally modified fluorogypsum, aggregate, water-retaining thickener and redispersible latex The fluorine gypsum-based interior wall plastering material can be obtained by stirring the powder evenly.

[0096] During construction, the fluorine gypsum-based interior wall plastering material was mixed with water according to the water-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com