Method of fermenting and composting feces of livestock and poultry

A technology of livestock manure and composting, applied in organic fertilizers, fertilization devices, excretion of fertilizers, etc., can solve the problems of soil and water environment pollution, effective removal of antibiotics and heavy metals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

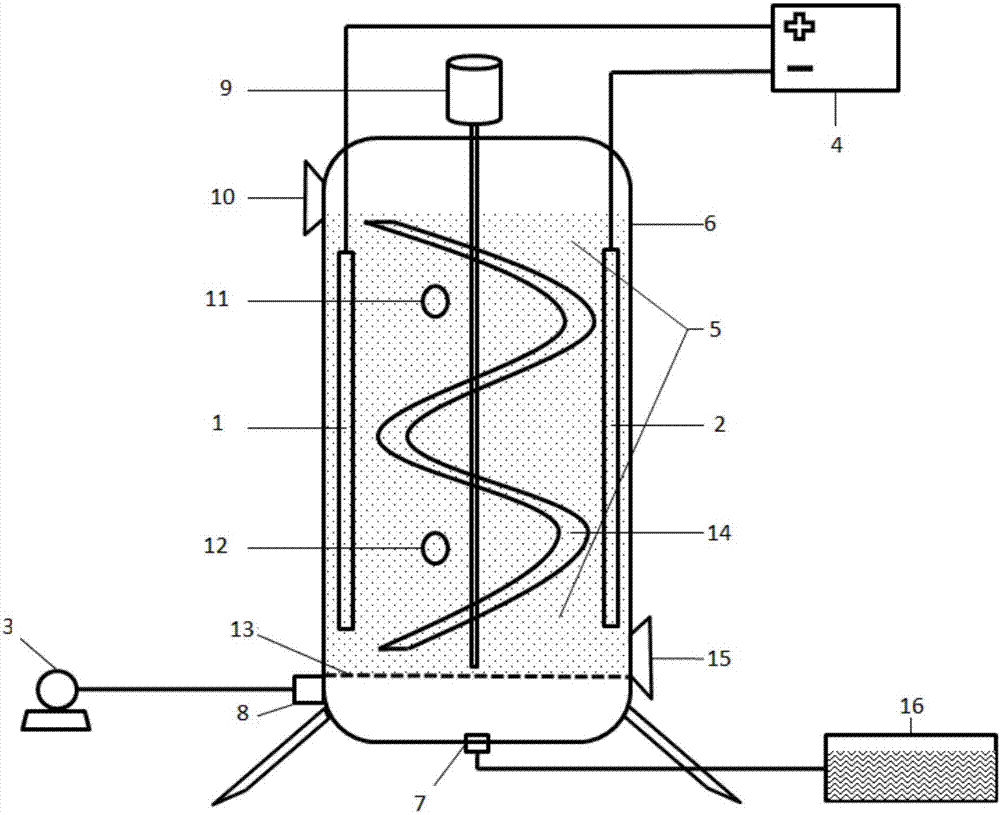

Image

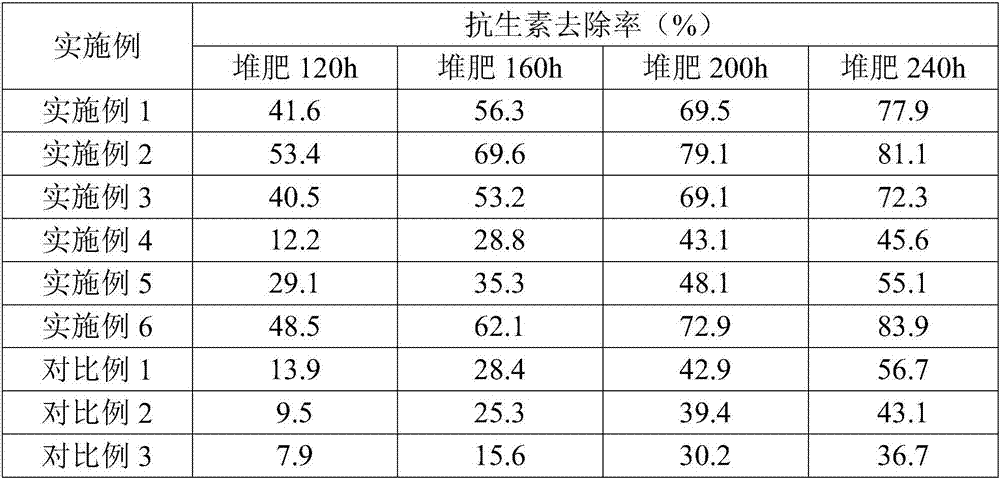

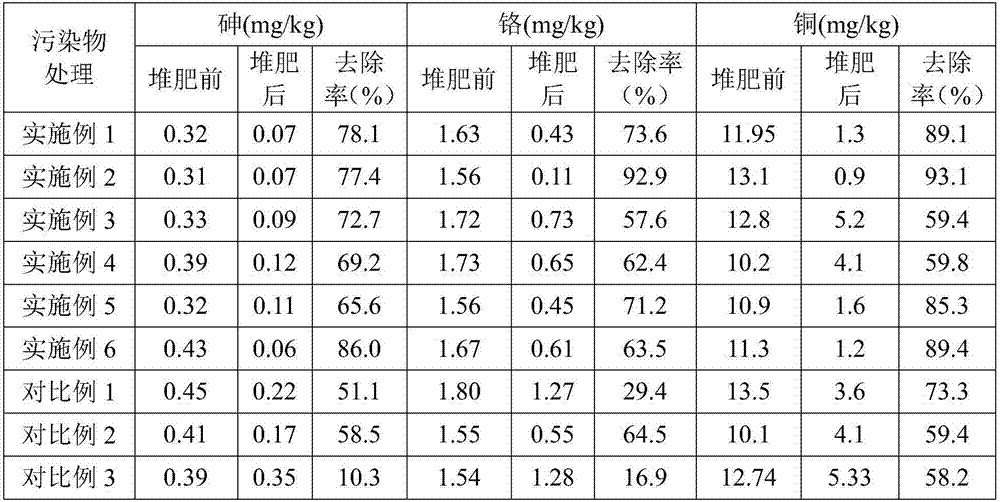

Examples

preparation example Construction

[0034] According to the present disclosure, the preparation method of the composite catalyst may further include: (d) the mineral powder combustion step of the step, including: the first combustion process, which is roasted by heating at a temperature of 50-300° C. for 2-3 hours; the second Combustion process, after the first combustion process is completed, the natural ore powder that has been burned for the first time is heated at a temperature of 300-850°C for 0.5-10 hours to perform the second combustion; in the mixing process step of (e), 60-80% by weight of crushed mineral powder into 45 micron-2 nanometer size, 20-30% by weight of H 2 0 and 2-10% by weight of the natural plant roots, stems and leaves of Geliflower are mixed to obtain the mixed powder; In the temperature range from -10°C to 200°C, ripen for 10-90 days for fermentation; (f) for the sterilization and drying step, sterilize in a roasting furnace at a high temperature below 180°C for 0.5-2 hours, and Dry at...

Embodiment 1

[0047] This example is used to illustrate the method for fermenting and composting poultry manure of the present disclosure.

[0048] use as figure 1 The device shown is for fermenting and composting poultry manure, and the mixed material is fresh pig manure (containing 21.1 mg / kg of tetracycline antibiotics, 0.32 mg / kg of arsenic ions, 1.63 mg / kg of chromium ions and 11.95 mg / kg of copper ions), Straw, after adjusting livestock and poultry manure and straw according to the ratio of carbon to nitrogen ratio of 20-25, add 0.3% composite catalyst, adjust the moisture content of the mixed material to 65%, the initial temperature is the ambient temperature, and the pH value is 7.8. Enter the device through the feed port 10, and apply voltage at both ends of the mixed material heap during the fermentation process, so that the organic matter, antibiotics and heavy metals in the mixed material heap undergo electrolytic reactions, compost for 10 days, and the compost filtrate is disch...

Embodiment 2

[0050] The raw materials, device and method of Example 1 are used to ferment and compost poultry manure, but the difference is that the amount of composite catalyst is 5% of the weight of poultry manure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com