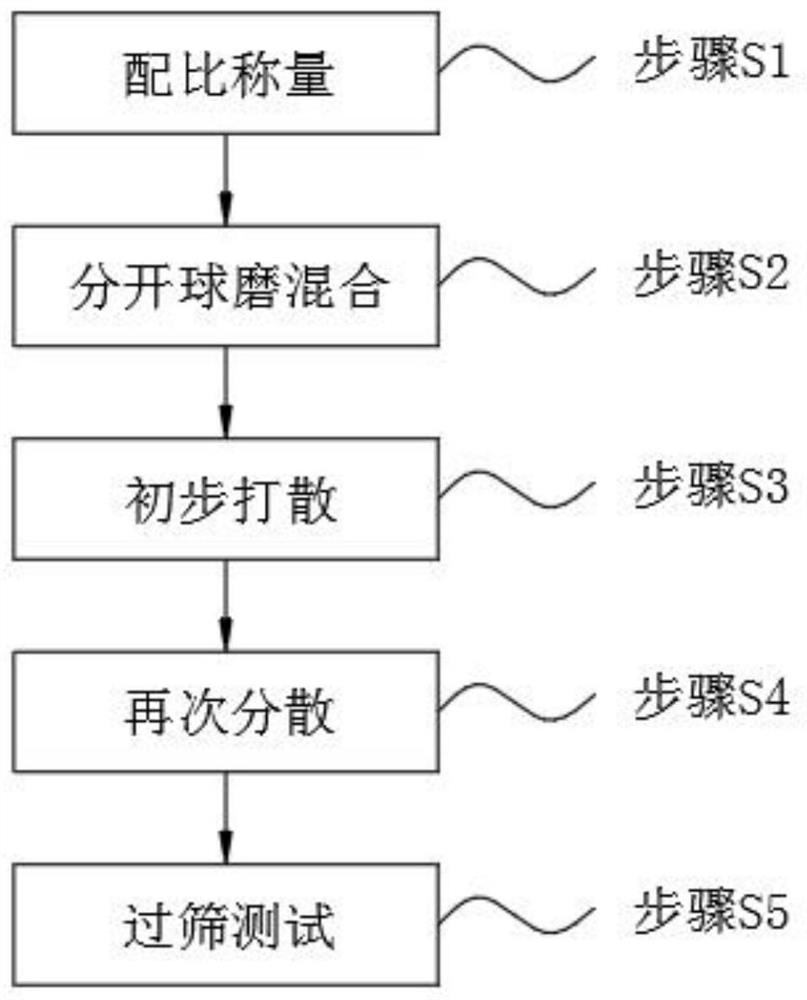

Mixing process for improving low-temperature performance of lithium battery

A low-temperature performance and mixed process technology, applied in the direction of lithium batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve problems such as poor work performance, achieve uniform dispersion, and improve the overall overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

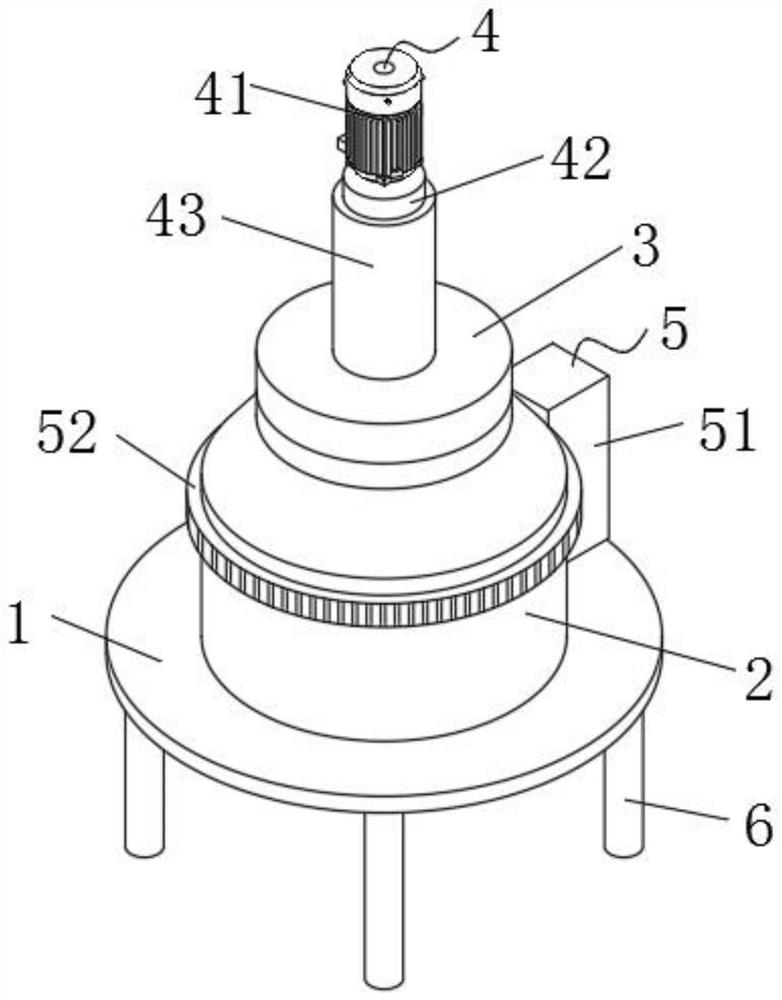

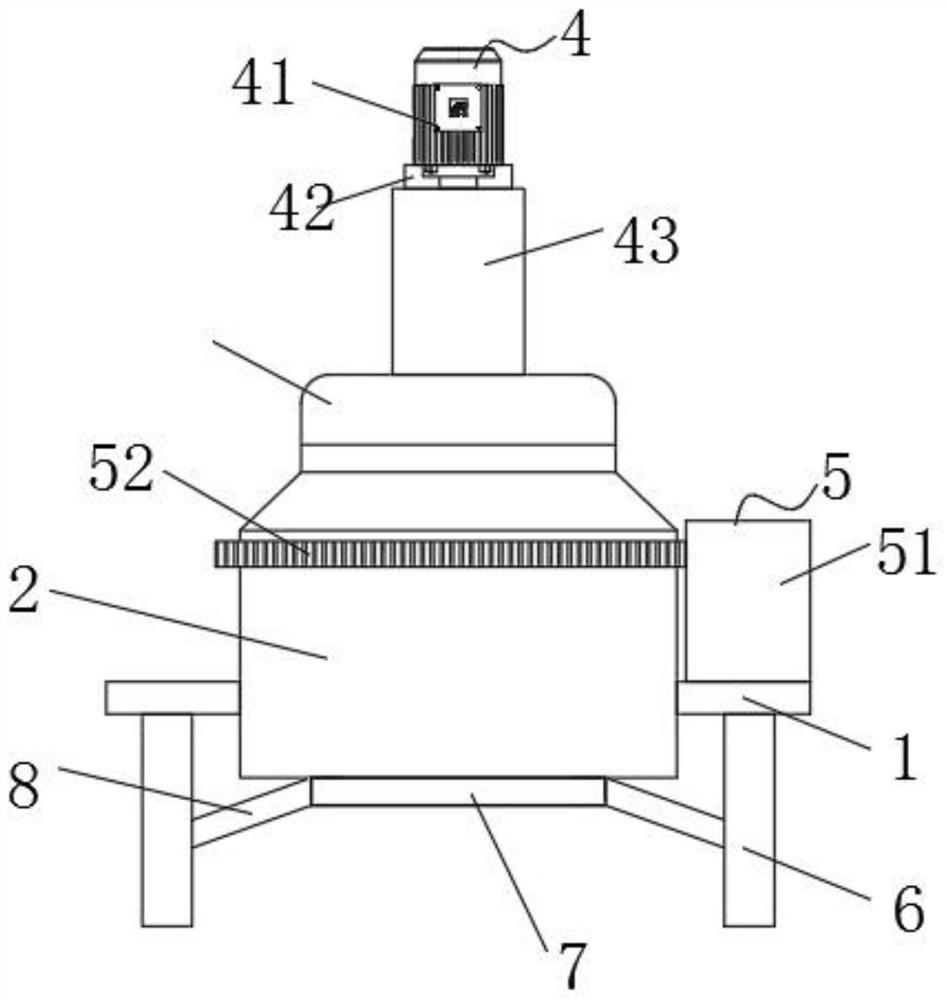

[0036] As an embodiment of the present invention, the dispersing equipment includes a bottom plate 1, a dispersing casing 2, a dispersing cover 3, a dispersing assembly 4, a rotating assembly 5 and a support leg 6, and the top center of the bottom plate 1 is embedded with the dispersing casing 2, and The top of the dispersing housing 2 is equipped with a dispersing cover 3, and the top of the dispersing cover 3 is embedded with a dispersing assembly 4, and the top side of the bottom plate 1 is provided with a rotating assembly 5, and the rotating assembly 5 is arranged on the side of the dispersing housing 2;

[0037]Dispersion assembly 4 comprises dispersion motor 41, fixed seat 42 and stable housing 43, dispersed motor 41 is installed on the top of stable housing 43 by fixed seat 42, and the output end of dispersed motor 41 runs through fixed seat 42 and stable housing 43 tops Fixedly connected with the top of the rotating shaft 47, the inside of the stabilizing housing 43 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com