Finish machining robot for large motor rotor after casting molding

A technology of casting and large-scale motors, which is applied in the manufacture of stator/rotor bodies, etc., can solve the problems of reducing work efficiency, high cost, and increasing labor intensity of workers, so as to achieve the effect of improving work efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

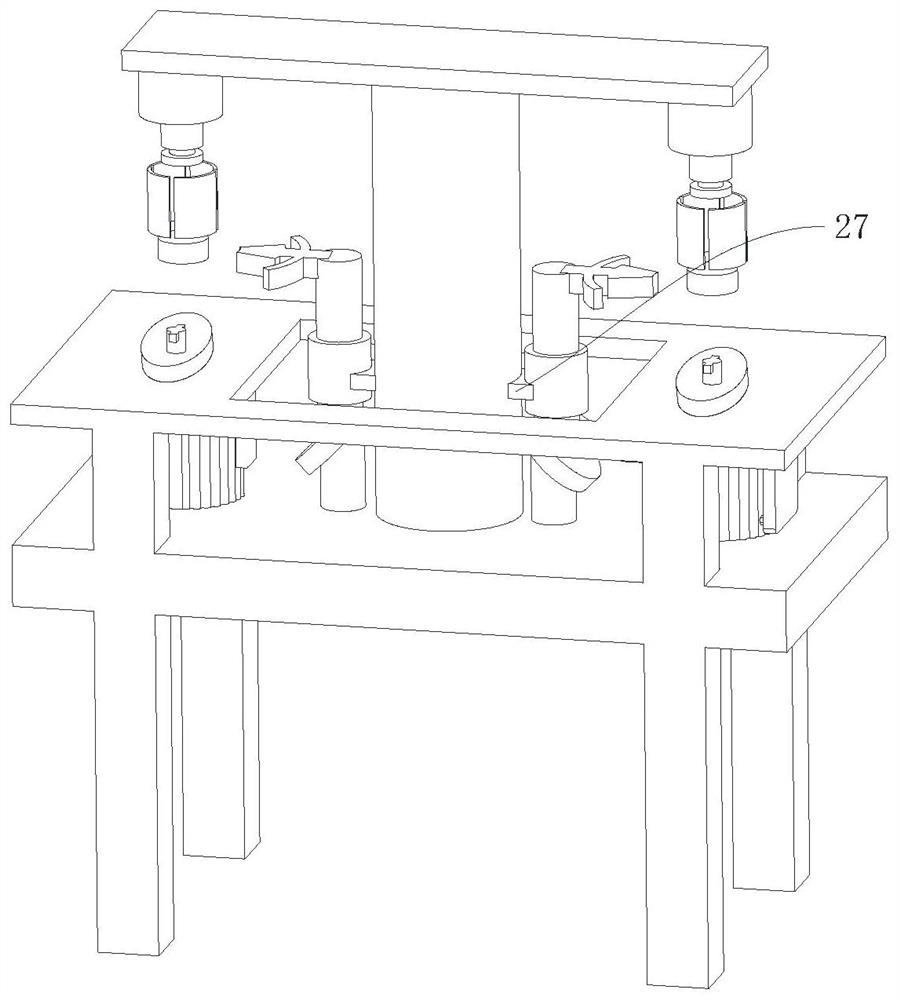

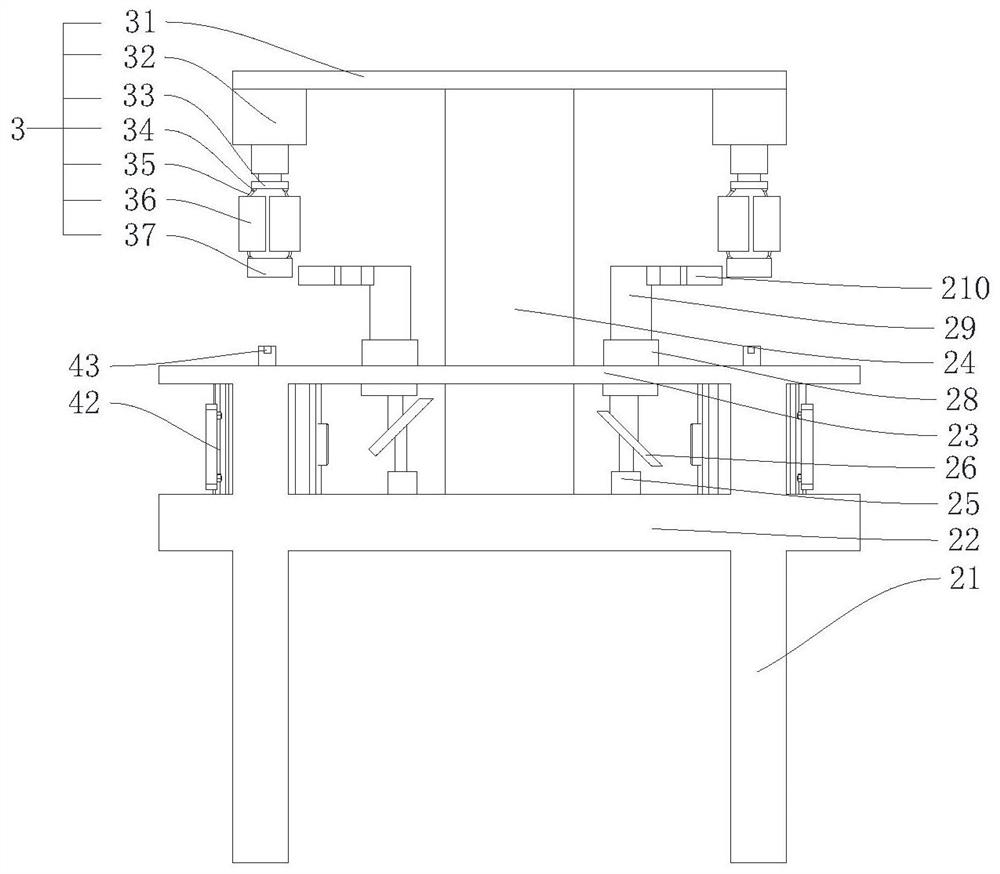

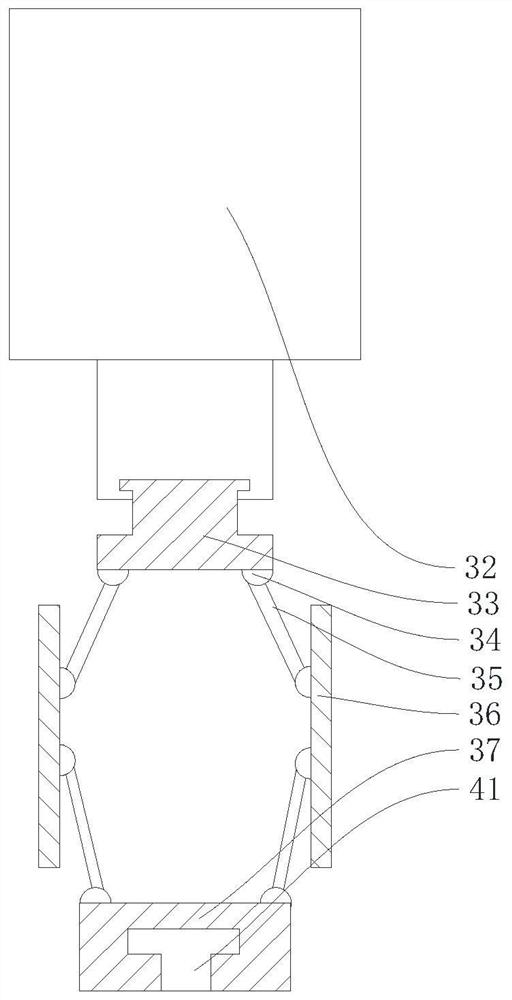

[0033] refer to figure 1 As shown, it is a large-scale motor rotor finishing casting robot disclosed in the present invention, which includes a motor rotor 1. In order to achieve automatic grinding, improve work efficiency, and reduce labor intensity, it includes an automatic grinding device for automatic grinding. 2 and a fixing device 3 for fixing the motor rotor 1;

[0034] refer to figure 1 , figure 2 as well as image 3As shown, the automatic grinding device 2 includes a mounting pillar 21, a mounting plate 22, a placing plate 23, a fixed column 24, a rotating motor 25, a rotating plate 26, a fixed plate 27, a limit cylinder 28, a sliding rod 29 and a grinding head 210; The installation pillars 21 are four quadrangular prism structural profiles made of metal, which are fixedly installed on the workshop floor by welding and set up vertically. In the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap