Automatic receiving and receiving ball training device

An automatic sending and receiving and training device technology, applied in the direction of sports accessories, etc., can solve the problems of wasting time, accidental injury of personnel, use cost, failure to recover the ball in time, etc., and achieve the effect of saving time and low use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

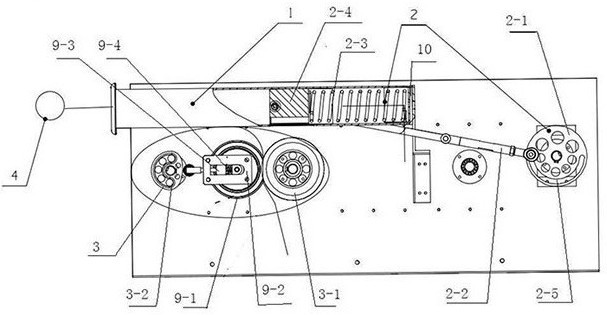

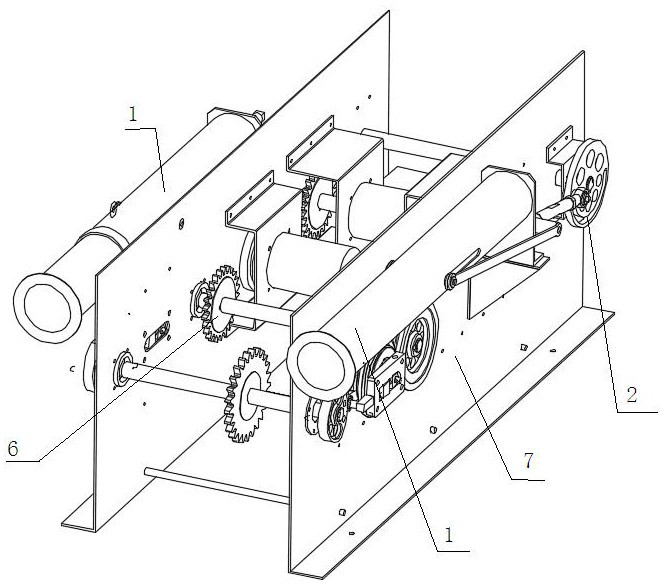

[0023] Such as figure 1 , 3 As shown, the automatic receiving and receiving ball training device includes the following technical characteristics.

[0024] (1) Fuselage 7, the fuselage 7 is an all-aluminum structure, and the fuselage 7 is used as the main body to install the directional control guide rope launcher 1, the cyclic elastic energy storage firing mechanism 2, and the mechanical cam cycle control friction rope retraction mechanism 3 Or an electronically controlled friction rope receiving mechanism 5; a power device is installed inside the fuselage 7, and the power device is a motor or a reducer connected with the motor.

[0025] (2) Orientation control guide rope launcher 1, directional control guide rope launcher 1 is cylindrical, directional control guide rope launcher 1 is installed on the fuselage 7, the port of directional control guiderope launcher 1 is forward, and directional control The rear end of the guide rope launching tube 1 is closed; there is a long...

Embodiment 2

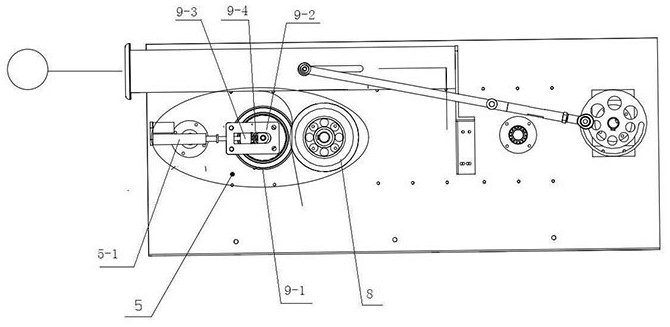

[0034] Such as figure 2 As shown, this embodiment adopts the electronically controlled friction rope receiving mechanism 5 instead of the mechanical cam period control friction rope receiving mechanism 3, and other structures are the same as those of the first embodiment.

[0035] The electric-controlled friction rope receiving mechanism 5 includes an electric push rod 5-1, which is fixed on the lower side of the directional control guide rope launching cylinder 1, and the rod end of the electric push rod 5-1 is connected with an elastic loading slider The body of rod end of the small slide block 9-3 of mechanism.

[0036] Such as figure 2 , the push rod of the electric push rod 5-1 pops up, pushes the friction disc 9-1 and the rope receiving disc 8 through the small slider to clamp the rope, and the rope receiving disc 8 rotates counterclockwise to drive the rope downward through the friction force to realize the rope receiving action; otherwise, the electric push rod 5-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com