Plastic injection mold based on heat dissipation

A heat-dissipating technology for injection molds, which is applied in the fields of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., and can solve problems such as staining, residue on the inner wall of the mold, and high heat in the mold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

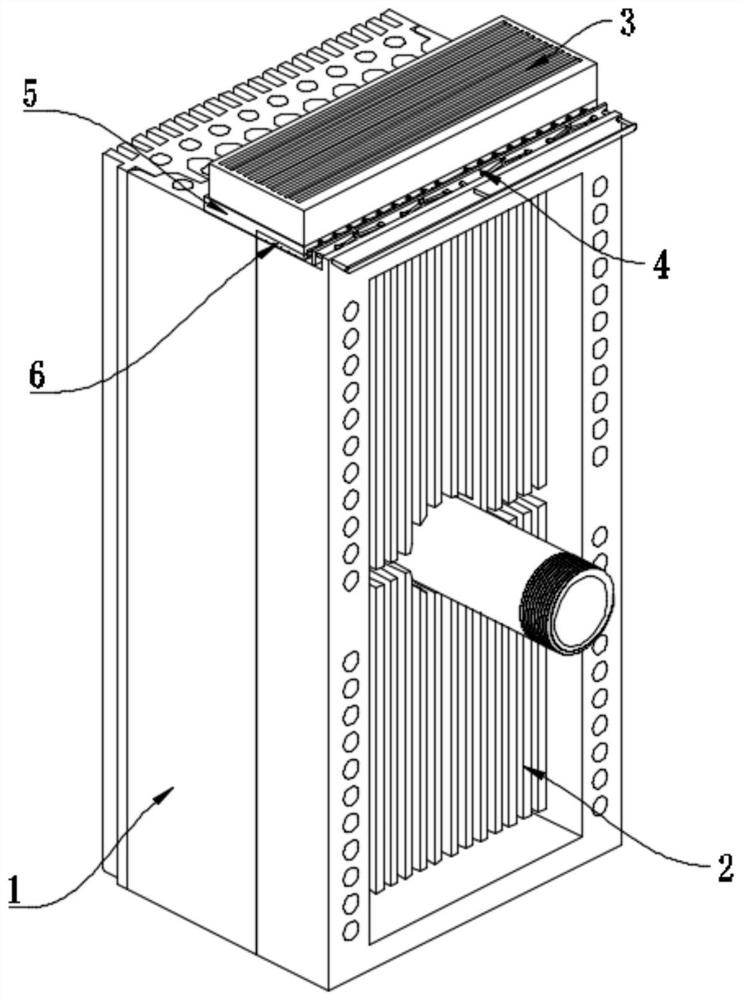

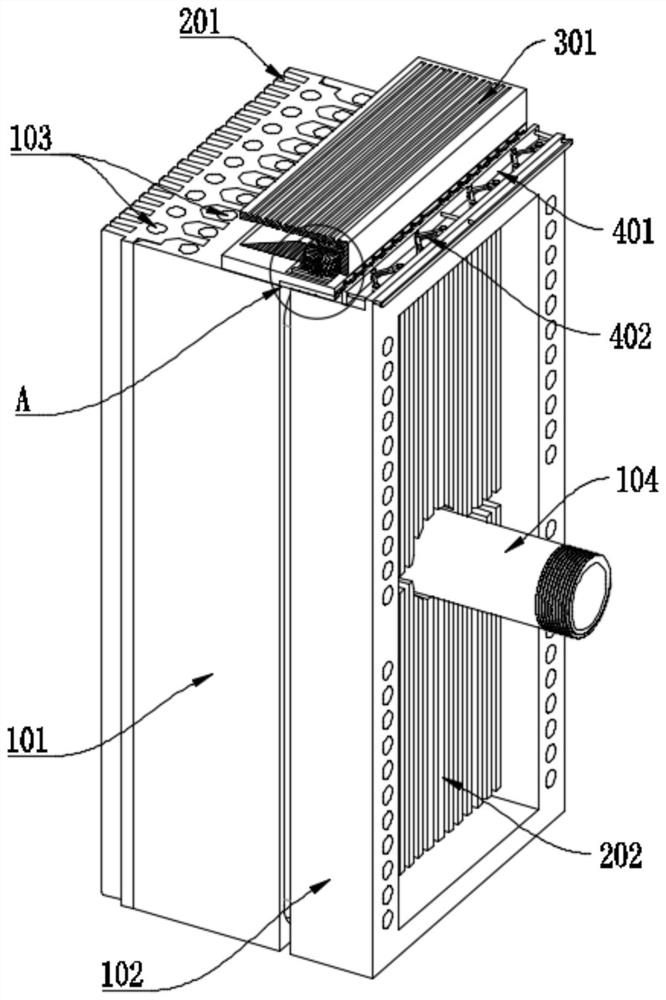

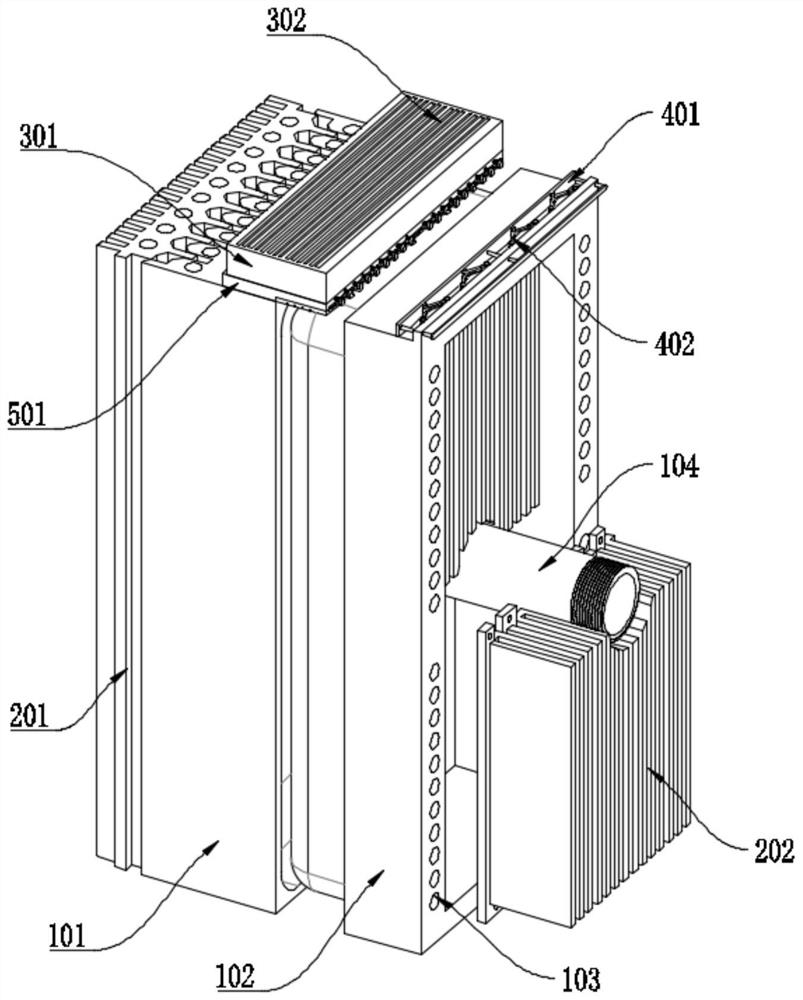

[0036] as attached figure 1 to attach Figure 9Shown:

[0037] The invention provides a plastic injection mold based on heat dissipation, which includes a mold structure 1; a heat dissipation structure 2 is arranged on the outer surface of the mold structure 1, and a fan structure 3 is arranged at the top of the mold structure 1; a spray nozzle is installed at the bottom of the fan structure 3. A medicine structure 5, and a one-way structure 6 is installed at the lower end of the medicine spraying structure 5; a discharge structure 7 is arranged between the one-way structure 6 and the medicine spraying structure 5; the fan structure 3 includes a fan box 301, a filter screen 302, and an air chamber 304 , mounting holes 305, the fan case 301 is arranged on the top of the mold structure 1, and the top of the fan case 301 is provided with a filter screen 302, the front end of the fan case 301 is provided with a mounting hole 305, and the inside of the fan case 301 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com