Constant-temperature transport vehicle for chemical industry chemicals

A chemical and chemical industry technology, applied in the field of chemical industry constant temperature transport vehicles, can solve some problems such as residual temperature, and achieve the effect of avoiding too high or too low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

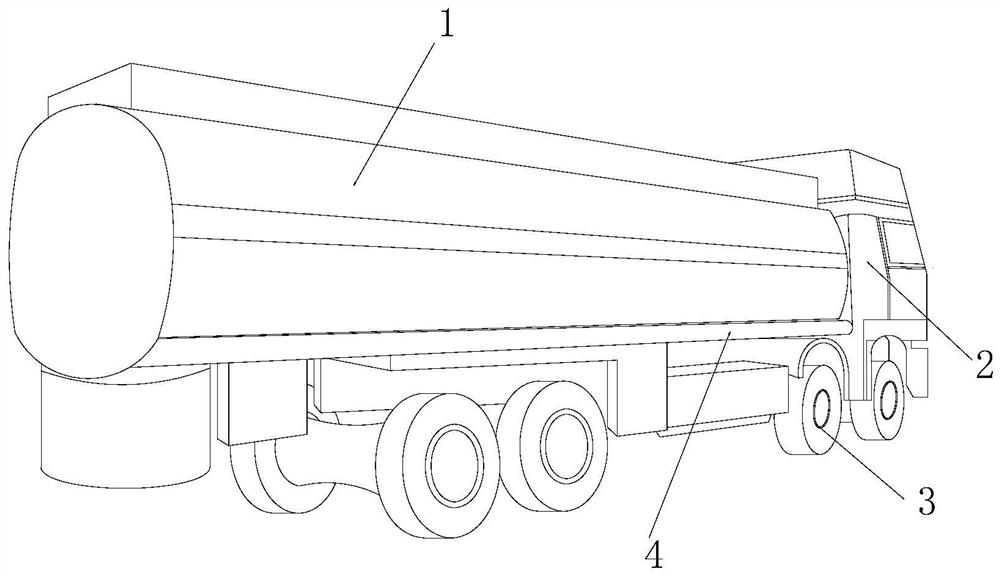

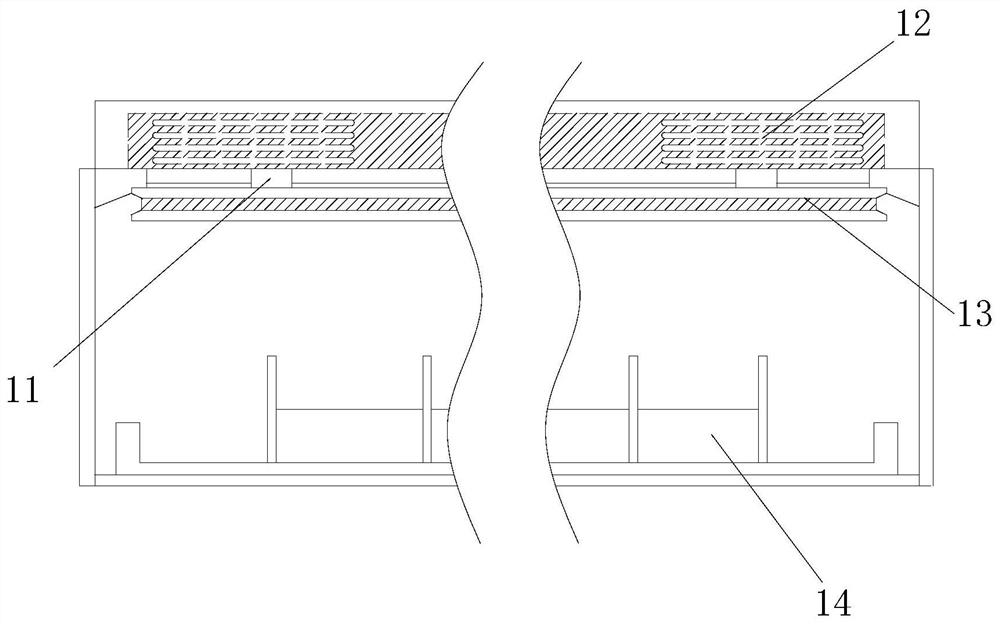

[0025] as attached figure 1 to attach Figure 5 Shown:

[0026] The present invention provides a chemical constant temperature transport vehicle for the chemical industry. Its structure includes a warehouse 1, a driver's cab 2, a driving wheel 3, and a vehicle body 4. The cargo warehouse 1 is embedded and installed on the back end surface of the driver's cab 2. Said driver's cab 2 is fixedly installed directly above the driving wheel 3, and said driving wheel 3 is evenly and symmetrically installed on the left and right sides of the lower end of the vehicle body 4, and said vehicle body 4 is inlaid directly below the warehouse 1; 1 includes a cooling port 11, a cooling air 12, a collection mechanism 13, and a placement table 14. The cooling port 11 is symmetrically installed on the left and right sides of the lower end of the cooling air 12, and the cooling port 11 is mounted on the lower end of the cooling air 12 , the collection mechanism 13 is embedded and installed direc...

Embodiment 2

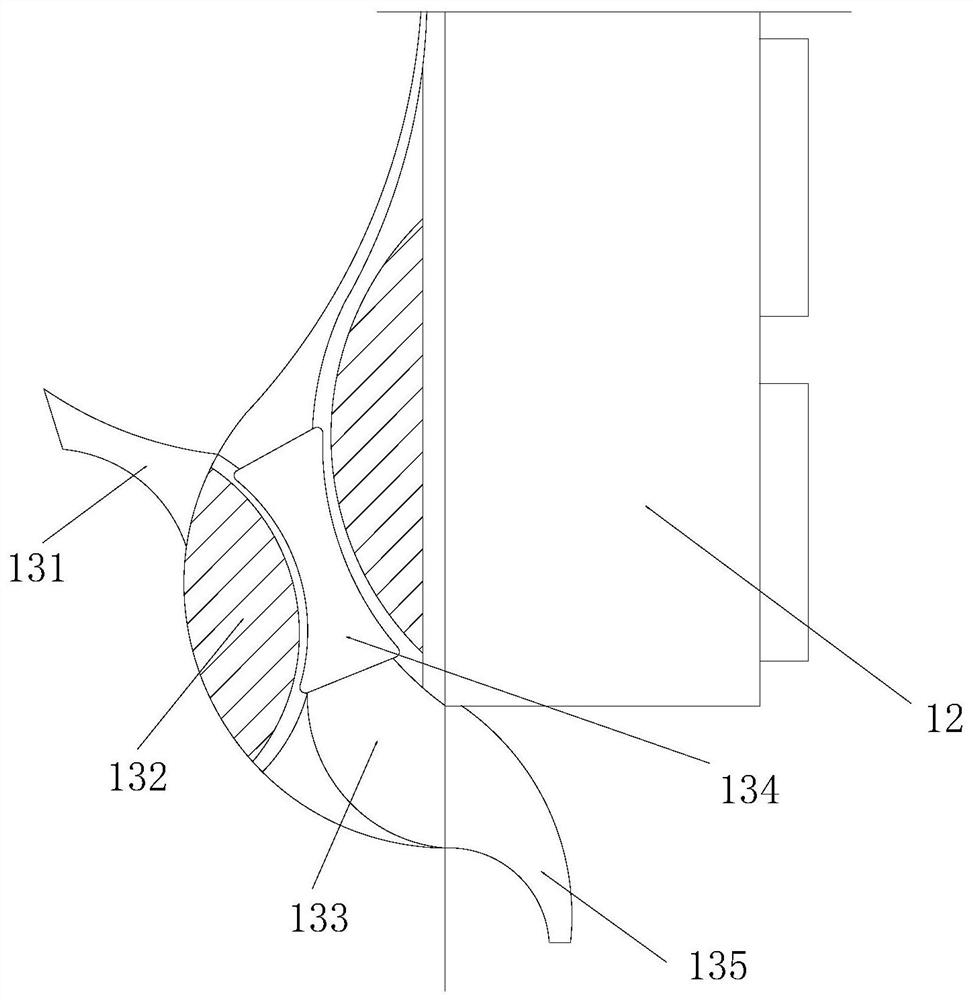

[0033] as attached Figure 6 to attach Figure 7 As shown: the heat preservation mechanism 132 includes an arc copper sheet 321, an embedding block 322, a second conductive layer 323, and a heat capacity groove 324, and the arc copper sheet 321 is inlaid and attached to the upper end of the second conductive layer 323 On the side, the embedding block 322 is symmetrically installed on the left and right sides of the lower end of the second conductive layer 323, the inner end surface of the second conductive layer 323 is attached to the heat capacity groove 324, and the arc of the arc copper sheet 321 The inner contour of the shape is consistent with the outer contour of the heat capacity groove 324 to form a wrapping shape, which is attached to the upper surface of the heat capacity groove 324, and can effectively and uniformly conduct the external low temperature to the inner side of the heat capacity groove 324 through the arc copper sheet 321 end.

[0034] Wherein, the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com