Washing barrel assembly and washing machine

A washing tub and component technology, applied in the field of washing machines, can solve the problems of shortening the soaking time of clothes and increasing the cost of electricity consumption, and achieve the effects of simplifying product composition, reducing structure cost and use cost, and good visual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

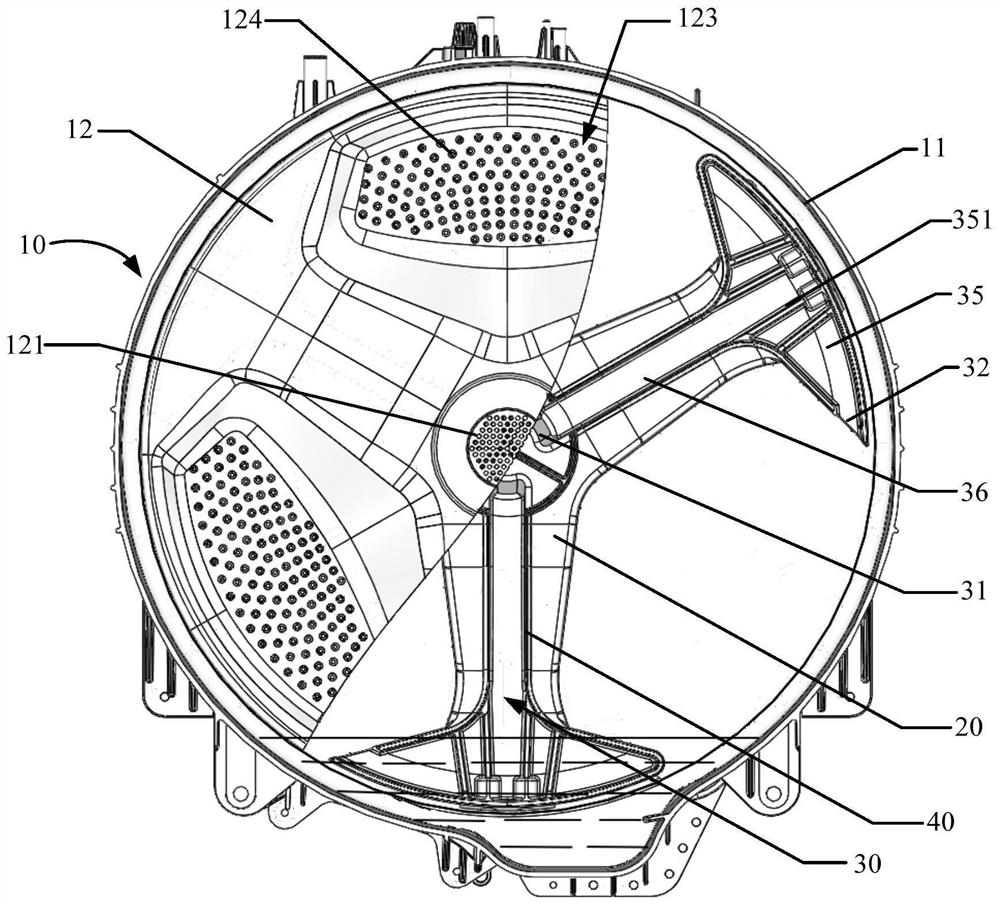

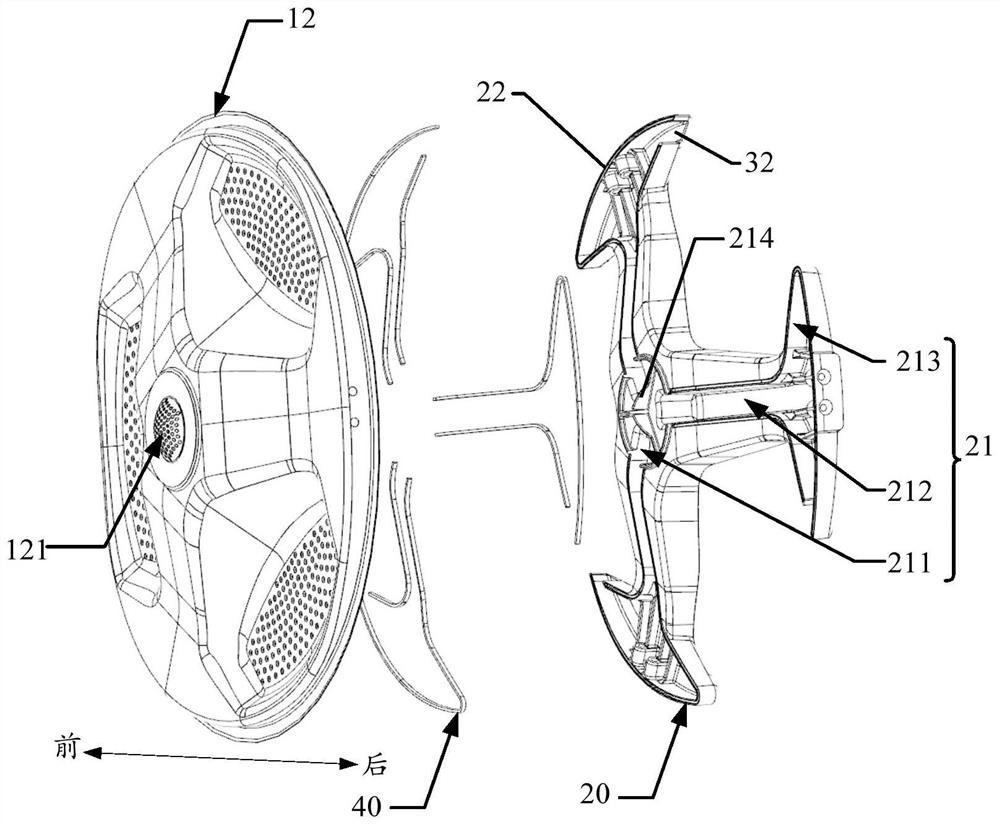

[0066] Such as figure 2 and Figure 7 As shown, in addition to the features of the above embodiments, it is further defined that: the flow channel 30 includes an expansion cavity 31 , the expansion cavity 31 is arranged corresponding to the water outlet 121 and communicated with the water outlet 121 , and the expansion cavity 31 communicates with the water inlet 32 . In this way, the support frame 20 and the rear cover 12 can form a flow channel structure with more sufficient space, thereby improving the water guiding efficiency of the flow channel 30 and further improving the spraying effect.

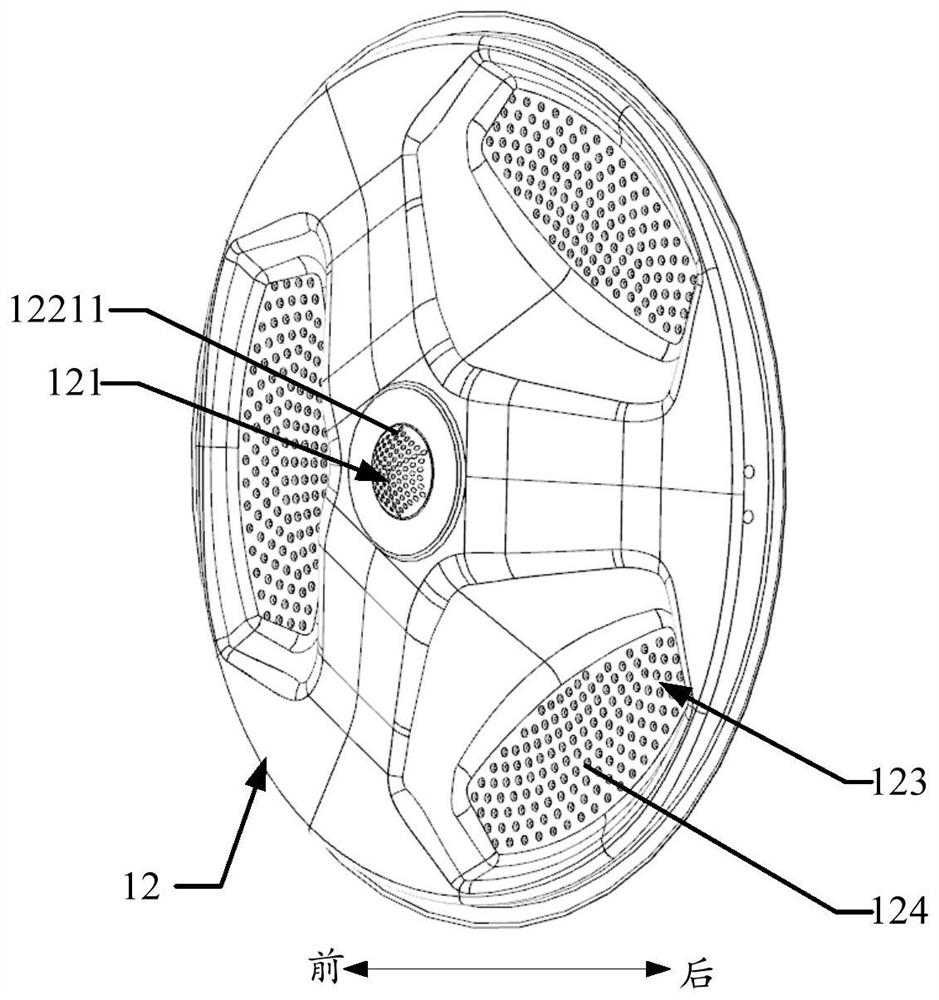

[0067] In detail, such as Figure 7 As shown, an expansion area 122 is formed on the back cover 12, and the expansion area 122 is surrounded by the support frame 20 to define the expansion cavity 31. The expansion area 122 includes a water outlet area 1221 and a sealing area 1222 arranged along the outer periphery of the water outlet area 1221. The water outlet area 1221 is provid...

Embodiment 2

[0070] Such as Figure 5 and Figure 7 As shown, in addition to the features of the above embodiments, it is further defined that: the expansion area 122 includes a boss wall 1223, and the boss wall 1223 includes a top wall 12231 and a side wall 12232, and the top wall 12231 is provided with a water outlet 121, as Figure 4 As shown, the support frame 20 is provided with an expansion cavity 211 and ribs 214 arranged along the opening of the expansion cavity 211, and the top wall 12231 is arranged opposite to the opening of the expansion cavity 211 and blocks the opening of the expansion cavity 211. The rib 214 is inserted into the space enclosed by the side wall 12232 .

[0071] For example, the convex platform wall 1223 and the expansion concave cavity 211 form a convex and concave expansion cavity 31, which further increases the capacity of the expansion cavity 31 to ensure the spray water output, thereby increasing the spray volume accordingly, and the convex ribs 214 are ...

Embodiment 3

[0073] Such as Figure 7 As shown, in addition to the features of any of the above-mentioned embodiments, it is further defined that: the expansion chamber 31 is provided with one or more water outlet retaining ribs 33, and one or more water outlet retaining ribs 33 will expand the space in the chamber 31 Divided into a plurality of water outlet chambers 34 , the flow channel 30 is provided with a plurality of water inlets 32 , and the plurality of water inlets 32 communicate with the plurality of water outlet chambers 34 correspondingly.

[0074]For example, the water outlet retaining rib 33 is set to divide the space in the expansion cavity 31 into a plurality of water outlet chambers 34 along the circumferential direction, and the plurality of water inlets 32 communicate with the plurality of water outlet chambers 34 one by one, so that each water inlet 32 flows to the corresponding water outlet chamber 34, the water in each water outlet chamber 34 will not flow away from e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com